Time Calculations in DPM

In DPM, time is used as currency for intuitive impact assessment and comparison of all metrics. Every loss type, from downtime to scrap, is normalized into the common unit of time to clarify the relative importance of the loss and to know exactly what is constraining your performance. This is accomplished by using the ideal cycle time to convert counts, such as scrap count, into time measurements. The ideal cycle time is defined for each material that is produced by the pacemaker for a given work center. For example, the ideal cycle time for Material A on Work Center 12 is 2 minutes, and 5 produced units fail quality inspection and must be scrapped. By multiplying the scrap count of 5 by the ideal cycle time of 2, the scrap count is converted into a time loss of 10 minutes.

By leveraging time as a business metric rather than using disconnected percentages, DPM allows for like-for-like comparison of data to better understand the relative impact of various loss types.

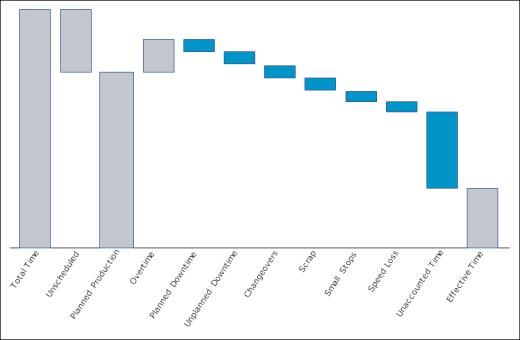

While these time calculations are used throughout DPM, they are most easily seen on the waterfall chart in Performance Analysis, which is similar to the following image.

The Total Time bar represents the total amount of time that is available for production, both scheduled and unscheduled. Scheduled time is time during a scheduled shift which is not designated as an overtime shift. The Unscheduled bar represents all time that is not part of a scheduled shift, thus not scheduled for production. Subtracting the Unscheduled time from the Total Time leaves the Planned Production time. The Planned Production bar represents all time during which the equipment is scheduled to be in production, that is all time that is part of a scheduled shift. The Overtime bar represents any time during which the equipment is in production outside of a scheduled shift and any shift that is designated as an overtime shift. The blue bars, other than Unaccounted Time, represent categories of time loss as accounted for by loss events entered in the Production Dashboard and through automation. The Unaccounted Time bar represents all the time loss that has not yet been accounted for by loss events. The Effective Time bar represents the amount of production time that is producing good product.

Calculations

The following table describes the high-level time calculations that are used in DPM and their formulae. All calculations are based on the date range and number of pacemakers that are being queried. In Performance Analysis or Action Tracker, these are the filter selections applied by the user. In Production Dashboard, these are the duration of the production block and the pacemaker for the selected work center.

Calculation | Description | Formula |

|---|---|---|

Effective Time | The amount of production time that is producing good product. | |

OEE | The key performance indicator (KPI) showing overall equipment efficiency. | |

Overtime | Any time during which equipment is in production outside of a scheduled shift (unplanned production) and any shift that is designated as overtime. A shift is designated as overtime when the Overtime checkbox is selected for the shift. Shifts that are designated as overtime are considered part of the Overtime calculation rather than the Scheduled Time calculation. Overtime shifts are not considered to be scheduled shifts. | Unplanned Production + (Overtime shift) |

Planned Production | Time during which equipment is planned to be in production. This is time during scheduled shifts and does not include overtime shifts. | |

Total Time | All time available for production, whether it is scheduled or unscheduled. | (Hours in the time range) * (number of pacemakers) |

Unaccounted Time | The difference between the operational time and production time, which has not yet been accounted for by loss events. | |

Unscheduled Time | Time during which equipment is not scheduled to be in production. This includes both time that is outside of a scheduled shift and any shift that is designated as overtime. |

Additional Calculations

The following table describes additional calculations used in DPM and how they are calculated.

Calculation | Description | Formula |

|---|---|---|

Actual Cycle Time | The time to produce one unit of material as calculated for the job order. This value is recalculated whenever a loss event or production count is added in the Production Dashboard, or an automated event (production count scrap count, loss event, or availability event) is received. | (Duration of all completed production blocks and the current production block up to the time of the latest production count entry, scrap count entry, or automated event) / (Produced Quantity for the job order through the current time) |

Available Time | The time during which the equipment is actually available for production. | |

Downtime | Time during which the equipment is non-operational or not available for production. | |

Estimated Completion Time | The date and time when the job order will be complete, based on the current date and time and the calculated time remaining to complete the job order. | |

Expected Production | For a production block: The number of units that can be produced during a production block, based on ideal cycle time. For a job order: The number of units that could be produced during all completed production blocks for the job order, based on ideal cycle time. | For a production block: (Length of the current production block) / Ideal Cycle Time For a job order: (Duration of all completed production blocks) / Ideal Cycle Time |

Operational Time | The time during which the equipment was actually operational and producing. | |

Performance Loss | The time lost to small stops and speed loss. | |

Produced Quantity | The total number of units produced, both good counts and scrap counts. Also referred to as production count. | |

Production Time | The time spent producing units for a job order. | |

Remaining Time | The calculated time remaining to complete the job order, based on the remaining quantity of units to be produced and the ideal cycle time. | |

Scrap Time | The time loss equivalent for scrapped product. | |

Time Loss (for a job order) | The calculated time loss for a job order, calculated as the good count multiplied by the ideal cycle time for the material, subtracted from the duration of all completed production blocks for the job order. | |

Total Time Loss (for a production block) | The calculated time loss for a completed production block, calculated as the length of the production block minus the good time (the good count multiplied by the ideal cycle time). | |

Time Loss Unaccounted For (for a production block) | The time loss for the production block that is not yet accounted for, calculated as the total time loss for the production block minus the duration of all non-scrap loss events and the scrap time (the scrap count multiplied by the ideal cycle time). |

Variables

The following table describes additional variables that are used within DPM calculations.

Variable | Description |

|---|---|

Changeover | Time spent re-configuring equipment to produce a different material. |

Current Time | The current date and time. |

Good Count | The quantity of the total produced units for a job order which pass quality inspection. |

Ideal Cycle Time | The ideal time to produce one unit of material. The ideal cycle time is defined on each work center which produces the material. |

Planned Downtime | Time during which the equipment is expected to be non-operational, for example, during routine maintenance. |

Production Block | A defined period of production during which operators are asked to account for all materials that are produced and for any time loss. For more information, see Production Blocks. |

Scheduled Time | Time during any scheduled shift. Shifts that are designated as overtime are not considered to be scheduled shifts. Overtime shifts are considered part of the Overtime calculation rather than the Scheduled Time calculation. |

Scrap Count | The quantity of the total produced units that fail inspection and must be scrapped. |

Small Stops | Time lost to minor stops in operation that are too small to be considered downtime. |

Speed Loss | A loss in efficiency while the equipment is operational. |

Target Quantity | The quantity of material to be produced for a job order. |

Unplanned Production | Any time during which equipment is in production outside of a scheduled shift. |

Unplanned Downtime | Unexpected time during which the equipment is non-operational, for example, during a power loss. |

Time Loss Accounted For (for a production block) | The total duration of all non-scrap loss events for the production block. |

Unknown | Time loss with an unknown cause. |