Production Blocks

A production block is a defined period of time during which operators are asked to account for all materials that are produced and for any time loss. This allows operators to enter data during production or at reasonable intervals, rather than trying to track and recall details at the end of a shift.

The standard duration of a production block is defined by an administrator for each site. By default, all work centers within that site inherit the production block duration from the site. The default standard production block duration is 1 hour. Each site, work center, and material configured for a work center can define the production block duration that makes the most sense for their use cases. Individual work centers can override the production block duration that is inherited from the site. The production block duration set for the work center is used for all materials that are produced by that work center, unless the production block duration is overridden for an individual material. For more information on setting the production block duration on an individual work center or material, see Material Settings Tab.

Production blocks are created for two reasons:

• Production blocks are created whenever a job order is in production, whether that production occurs during or outside of a scheduled shift. When production for a job order starts, a new production block is created. The production block ends when the standard production block duration has elapsed, when a shift starts, when a shift ends, or when production for the job order stops. As long as the job order is in production, the next production block is automatically created when the previous production block ends. These production blocks are all associated with the job order that is in production.

• Production blocks are created for the gaps in time during a scheduled shift when there is no job order in production. These time gap production blocks are created when production for the next job order starts or when the shift ends. The duration for a time gap production block does not follow the standard production block duration. A time gap production block lasts as long as necessary to cover the time gap between job orders and shift changes. Time gap production blocks are not associated with a job order. Loss events, other than scrap loss events, can be logged against these time gap production blocks. Production count and scrap loss events cannot be logged against time gap production blocks as there is no production during that time.

Only one production block at a time exists for a work center.

The following sections provide examples of how production blocks are created in different scenarios:

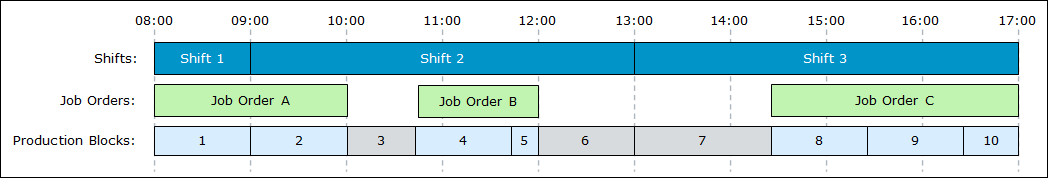

Example: Production Blocks with Continuous Shifts

The following image shows the production blocks that are created over a series of continuous shifts, with gaps between job orders.

In this example, Shift 1 starts outside of the time shown in the image and ends at 09:00. Shift 2 is from 09:00 to 13:00. Shift 3 is from 13:00 to 17:00. The standard production block duration for the site to which this work center belongs is 1 hour.

• Job Order A is in production from 08:00 to 10:00.

◦ Production Block 1 is created when production for Job Order A starts. It begins at 08:00 and ends at 09:00 when the standard production block duration has elapsed and Shift 1 ends. Production Block 1 is associated with Job Order A.

◦ Production Block 2 is automatically created when Production Block 1 ends, beginning at 09:00 and ending at 10:00 when production stops for Job Order A. Production Block 2 is associated with Job Order A.

• Job Order B is in production from 10:45 to 12:00.

◦ Production Block 3 is created when production for Job Order B starts to cover the time gap between Job Order A and Job Order B. This production block begins at 10:00 and ends at 10:45. Production Block 3 is not associated with any job order.

◦ Production Block 4 is created when production for Job Order B starts. It begins at 10:45 and ends at 11:45 when the standard production block duration has elapsed. Production Block 4 is associated with Job Order B.

◦ Production Block 5 is automatically created when Production Block 4 ends, beginning at 11:45 and ending at 12:00 when production stops for Job Order B. Production Block 5 is associated with Job Order B.

• Production Block 6 is created when Shift 2 ends to cover the time gap between Job Order B and the end of the shift. This production block begins at 12:00 when production is stopped for Job Order B, and ends at 13:00 when Shift 2 ends. Production Block 6 is not associated with any job order.

• Job Order C is in production from 14:30 to 17:00.

◦ Production Block 7 is created when Job Order C starts, to cover the time gap between the start of Shift 3 and the start of Job Order C. This production block begins at 13:00 and ends at 14:30. Production Block 7 is not associated with any job order.

◦ Production Block 8 is created when production for Job Order C starts. It begins at 14:30 and ends at 15:30. Production Block 8 is associated with Job Order C.

◦ Production Block 9 is automatically created when Production Block 8 ends, beginning at 15:30 and ending at 16:30. Production Block 9 is associated with Job Order C.

◦ Production Block 10 is automatically created when Production Block 9 ends, beginning at 16:30 and ending at 17:00 when production stops for Job Order C. Production Block 10 is associated with Job Order C.

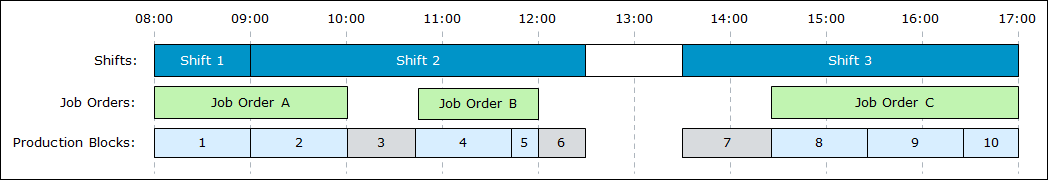

Example: Production Blocks with a Gap Between Shifts

The following image shows the production blocks that are created for a series of shifts, when there are gaps between job orders and between scheduled shifts.

In this example, Shift 1 starts outside of the time that is shown in the image and ends at 09:00. Shift 2 is from 09:00 to 12:30. Shift 3 is from 13:30 to 17:00. There is a gap between shifts from 12:30 to 13:30. The standard production block duration for the site to which this work center belongs is 1 hour.

• Production Block 1 and Production Block 2 are created for Job Order A while it is in production.

• Production Block 3 is created when production for Job Order B starts to cover the time gap during Shift 2 between Job Order A and Job Order B.

• Production Block 4 and Production Block 5 are created for Job Order B while it is in production.

• Production Block 6 is created when Shift 2 ends to cover the time gap between Job Order B and the end of the shift.

• No production block is created for the time gap between Shift 2 and Shift 3. There is neither a job order in production nor a scheduled shift during this time.

• Production Block 7 is created when production begins for Job Order C to cover the time gap between the start of Shift 3 and the start of production for Job Order C.

• Production Block 8, Production Block 9, and Production Block 10 are created for Job Order C while it is in production.

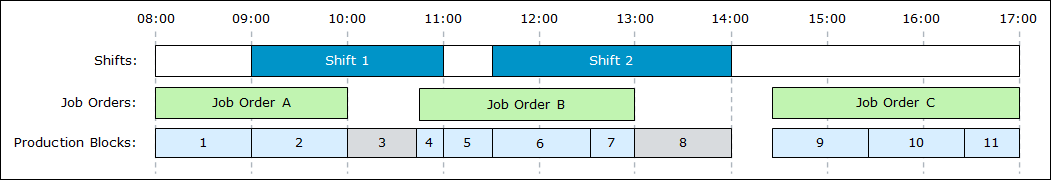

Example: Production Blocks and Overtime

The following image shows the production blocks that are created when job orders are in production outside of scheduled shifts. Any time during which a job order is in production outside of a scheduled shift is considered to be overtime. If a production block starts as overtime, while there is no scheduled shift, it ends when a new shift starts or production stops on the job order.

In this example, Shift 1 is from 09:00 to 11:00 and Shift 2 is from 12:00 to 14:00. Production for Job Order A happens both outside of and during Shift 1. Production for Job Order B happens both during and outside of Shift 1 and Shift 2. Production for Job Order C happens entirely outside of any scheduled shift.

• Production Block 1 and Production Block 2 are created for Job Order A while it is in production. All of Production Block 1 is considered overtime because it occurs outside of Shift 1.

• Production Block 3 is created when production for Job Order B starts to cover the time gap during Shift 1 between Job Order A and Job Order B.

• Production Block 4, Production Block 5, Production Block 6, and Production Block 7 are created for Job Order B while it is in production.

◦ Production Block 4 ends when Shift 1 ends.

◦ Production Block 5 is automatically created when Production Block 4 ends, and ends when Shift 2 starts.

◦ Production Block 6 is automatically created when Shift 2 starts. It ends after the standard production block duration has elapsed.

◦ Production Block 7 is automatically created when Production Block 6 ends, and ends when production stops for Job Order B.

• Production Block 8 is created when Shift 2 ends, to cover the time gap between production stopping for Job Order B and the end of Shift 2.

• Production Block 9, Production Block 10, and Production Block 11 are created for Job Order C while it is in production. All three production blocks are considered to be overtime because they occur outside of a scheduled shift.

• No production blocks are created for the time between the end of Shift 2 and the start of production on Job Order C. There is neither a job order in production nor a scheduled shift during this time.