Managing Routing Plans

A routing plan is a manufacturing object that can be used in various scenarios, including validation. The routing plan object enables you to experiment with various scenarios before finalizing a process plan. For a process plan, you can create multiple routing plans. That is, you can associate multiple routing plans with a process plan.

Consider a scenario where you want to localize or run a process plan in your plant. You have two ways to evaluate the process plan for the time and cost. In such a case, a routing plan object is beneficial. You can create two routing plans to analyze and validate various structures or plans. You can use these two routing plans to perform localization in two different ways. For the first routing plan, you open the routing plan in Visualization, place the tools, check the ergonomic strategy, perform other tasks, and then get a result. You can perform similar tasks for the other routing plan. Then, you can compare the results to determine which routing plan better suits your business needs. This analysis helps in optimizing the process plan.

Refer the video for more details. To view the video in a larger window, click on the video title. This opens the video in YouTube in a new tab.

A routing plan requires a process plan, Bill of Material (BOM), and plant for its proper functioning. A routing plan acts as a link between these three entities.

You can use a routing plan as a production version. A routing plan determines which process plan should be used with which BOM for a specified quantity in a specific plant.

Optimizing the flow of material is an essential factor that contributes to improving productivity and reducing the manufacturing process cost. This flow could be related to how the material flows in the plant or how you route the manufacturing process plan in a plant. A routing plan enables you to define the flow of material or process plan in the plant and also optimize the flow and manage the artifacts, such as documents, processing resources, tools, and so on.

A routing plan helps you make the following decisions:

• Process to be followed based on quantity, date, lot.

• Tools, line, or work center to be used.

• How to utilize plant capabilities to optimize production if the quantity varies. For example, if the system must produce 100 quantities of Part A, it uses Process Plan 1, Line 1, Workstation 1, Operation 1, and Tool 1.

If it must produce 1500 quantities of Part A, it uses Process Plan 1, Line 1, workstation 2, Operation 1, and Tool 2. The system can also use a different process plan to produce 1500 quantities of Part A.

Benefits

A routing plan manufacturing object provides the following benefits:

• Enables you to try different scenarios before the actual production.

• Proactively validates the manufacturability of product designs, and reduces errors between engineering and production.

• Significantly reduces the time and cost spent on manufacturing activities.

• Improves productivity and user experience. With improved productivity and user experience, visualizing an actual manufacturing line that includes various manufacturing entities becomes easier.

Key Points

• You can associate multiple routing plans with a process plan.

• A routing plan object contains the following information:

◦ Part that is going to be produced in a certain quantity

◦ The process followed while producing the part

◦ The plant used to produce the part

• A routing plan needs the following entities for its proper functioning:

◦ A process plan — contains the operation information.

◦ BOM — defines what needs to be produced.

◦ Plant — specifies which plant and line will be used to produce the actual component or product.

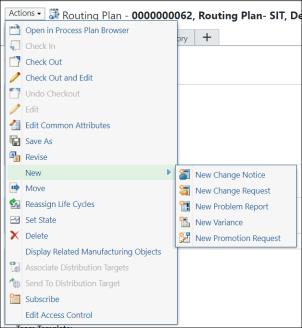

• A routing plan is a subset of a process plan. Use the Open in Process Plan Browser action to open a process plan in context of a routing plan. For more information, see Opening Routing Plan in Process Plan Browser.

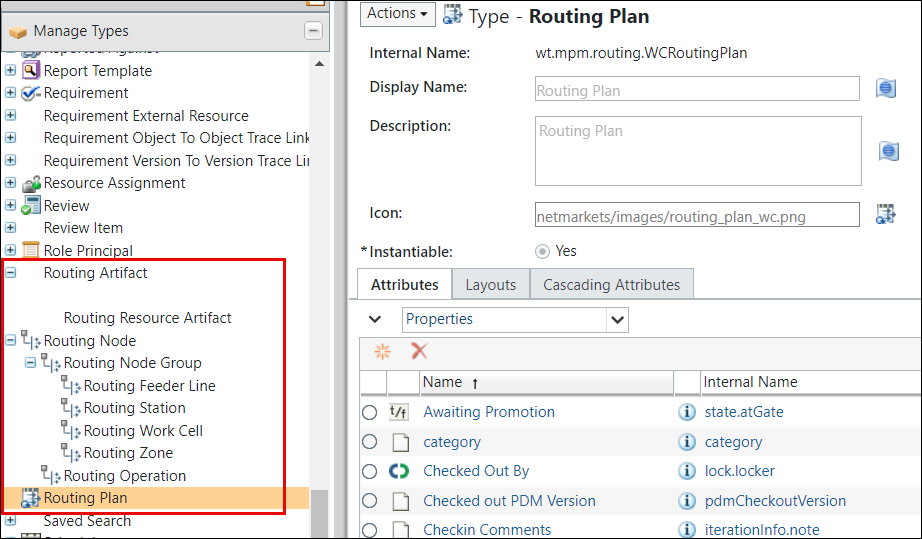

• The Type and Attribute Management utility contains the following entities related to a routing plan:

◦ Routing Plan

◦ Routing Artifact

▪ Routing Resource Artifact

◦ Routing Node

▪ Routing Node Group

▪ Routing Feeder Line

▪ Routing Station

▪ Routing Work Cell

▪ Routing Zone

▪ Routing Operation

For more information, see Working with the Type and Attribute Management Utility.

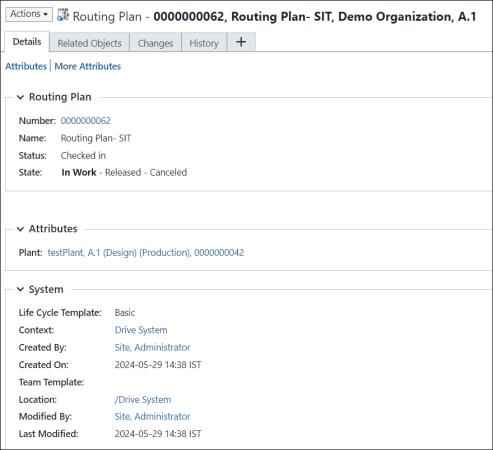

• The following layouts are available for a routing plan:

You can customize the layout and add new attributes according to your business requirement. For more information about attribute layout, see Layouts Tab and Editing Attribute Layouts.

• A routing plan object also supports cascading attributes.

Terminology Used in Routing Plan Features

The following terms are specific to the routing plan functionality in MPMLink.

Term | Definition |

|---|---|

Zone | A zone-based manufacturing approach is applied to manufacturing processes at an assembly line's workstation. Consider a workstation where the process of assembling four car doors is taking place. Four different operators are engaged at the same station. The operators are assembling the left front, right front, rear left, and rear right doors, respectively. In such scenario, the workstation can be considered to be virtually divided into four zones, where each zone consists of different operations being performed. You can allocate different operations to the different zones. For more information, see Adding a Zone in the Routing Plan Tab. |

Side and Level Attributes | Attributes defined for a Workcenter. These two attributes are most effective when working with zones. The Side attribute is only applicable for a feeder line and zones. That is, the system uses the value set for the Side when dealing with a feeder line or zones. The Level attribute is used by the system when it deals with zones. For more information, see Adding a Zone in the Routing Plan Tab and Using the Side and Level Attributes. |

Workcenter | A physical resource or a set of resources that can be assigned to an operation (for example, lines, work units, work cells, resource pools, workstations, and feeders). |

Feeder Line | A secondary assembly line that provides parts for use in a primary assembly line. |

For more information, see the following topics: