Processing a Shipment with Inventory Updates

When parts are ready to ship to the location specified in a Shipment Order, you should process the shipment in ServiceMax for inventory accountability and to complete the Shipment Order.

To process shipments for a Shipment Order:

1. Locate the Shipment Order by searching in the sidebar or from a list view in Parts Order tab and then click the Shipment Order number associated with the shipment you want to process. Ensure that the Shipment Order is Open and the destination location is not blank. Also ensure that the Shipment Order has at least one product to be shipped.

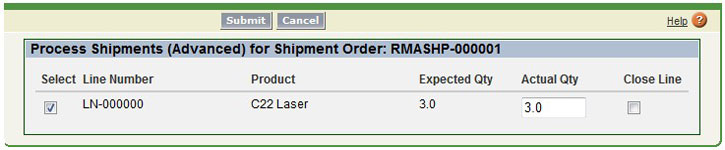

2. Click Process Shipments (Inv). A screen is displayed where you can enter the actual shipment information. The screen lists all products in the Shipment Order that are not yet shipped. The Quantity Shipped is defaulted to the pending quantity requested.

3. Click Submit to confirm the entries. The Shipment Order screen will be refreshed and the Shipment Order Line and Shipment Order Status are updated.

4. If your organization tracks inventory at the serial number level, the bottom section of the screen allows you to enter/select serial numbers for serialized products. To enter serial numbers for a product, check the check box against the product in the list. For more information about how serialized tracking of inventory works, see Serial Number Selection.

A serialized product is shipped to a non-stocking location. The Available stock the source location is reduced by the shipped quantity, and DECREASED stock at the source location is increased by the shipped quantity. The shipped serials are associated with the DECREASED stock record. |

When entering shipped quantities, one or more of the following scenarios might be applicable:

Shipment Scenario | How to Process it |

|---|---|

All the products in the Shipment Order have been shipped as requested. | Click Submit. All the open lines and the Shipment Order will be closed automatically. |

A product has not been shipped now but may be later. | Enter Zero in Actual Qty. Ensure that the Close Line check box is unchecked. This leaves the line open for future shipment. |

A product has not been shipped and it will not be shipped at all. | This amounts to the cancellation of an open Shipment Order Line. Enter Zero in Actual Qty. Ensure that the Close Line check box is selected. If your organization does not permit short-closing lines, this check box might be disabled. |

A product has been shipped partially now. The remaining quantity is expected to be shipped later. | Enter the quantity shipped. Ensure that the Close Line checkbox is unchecked. This leaves the line open for future shipment. |

A product has been shipped partially now. The remaining quantity will not be shipped at all. | This indicates the short-closure of a Shipment Order Line. Enter the quantity shipped. Ensure that the Close Line checkbox is checked. If your organization does not permit short-closing line, this check box might be disabled. |