Estimate Management

Depot repairs on assets often involve non-covered labor, parts, or expenses. Asset 360 allows you to create Estimate Work Orders with a list and customized pricing so that you can present your end customers with an estimate prior to commencing work on the repair of the asset.

The depot technician is involved in the depot repair process.

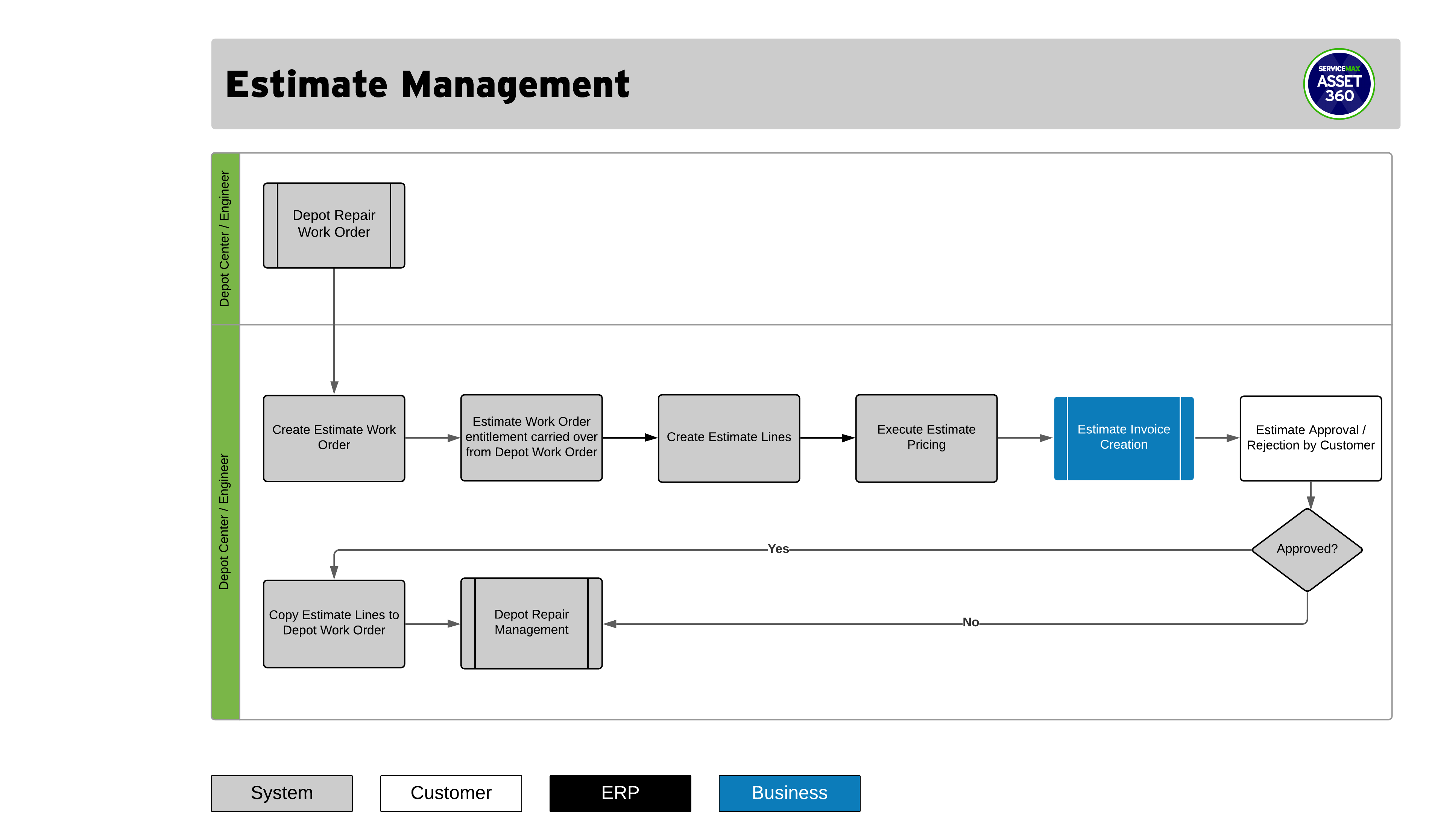

The following diagram displays the depot repair estimate process.

The following steps explain the Estimate Management process.

1. Create estimate work order: The depot engineer creates an Estimate Work Order from the Depot Work Order.

2. Create estimate lines: The depot engineer reviews and creates line items for the Estimate Work Order.

3. Execute estimate pricing: The depot engineer executes pricing for the repair items.

4. Create estimate invoice: The estimated invoice is generated with the total pricing.

Sample estimate invoices are not provided out of the box as Service Reports can not yet be packaged. Customers can create a Service Report specific to their business needs based on the Estimate Work Order provided. |

5. Approve or reject estimate: The customer approves or rejects the estimate.

6. Copy estimate lines to depot repair: If approved, the estimate lines are copied to the Depot Work Order.

7. Debrief depot work order: The depot engineer debriefs the repair of the asset by indicating any parts, labor, travel, and/or expenses consumed.