Recommendations for Successful Solidification

Consider the following recommendations for the successful solidification of the laminate objects:

• The entire layup surface must be smooth with no sharp edges. You can use the Connection Analysis tool to perform a tangency check on the layup surface. When the tangency check passes, it indicates that the layup surface is smooth with no sharp edges. To learn how to use the Connection Analysis tool, see Analyzing Connections in Surfacing.

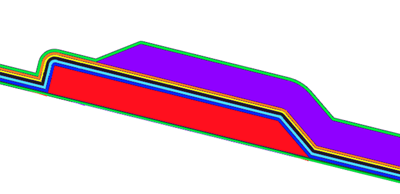

◦ The next figure shows a layup surface that passed the tangency check. It is suitable for solidification.

◦ The next figure shows a layup surface with failed tangency check. It is unsuitable for solidification.

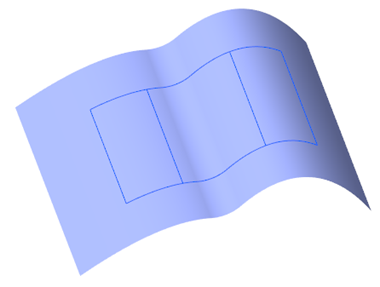

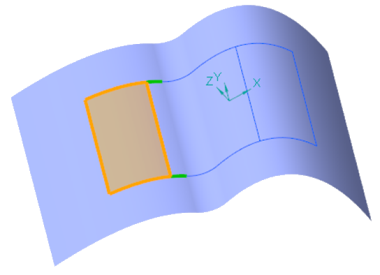

• The boundaries of the ply must not overlap the boundary of the layup surface.

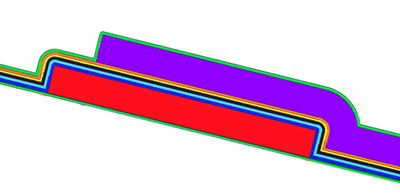

◦ The next figure shows the boundary of a ply is within the boundary of the layup surface and it does not overlap the boundary of the layup surface. This boundary is suitable for creation and solidification of the ply.

◦ The next figure shows the boundary of a ply overlaps the boundary of the layup surface. This boundary is unsuitable for creation and solidification of the ply.

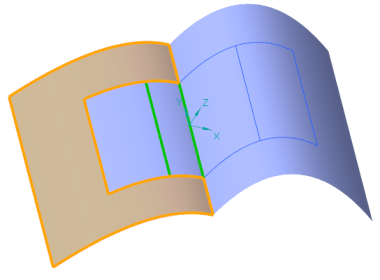

• One or more cores with tapers must not overlap one another.

◦ The next figure shows overlapping of cores that does not have tapers. This overlapping is suitable for solidification.

◦ The next figure shows the overlapping of cores that have tapers. This overlapping is unsuitable for solidification.