Recommendations for Successful Draping Simulation

Consider the following recommendations for the successful draping simulation:

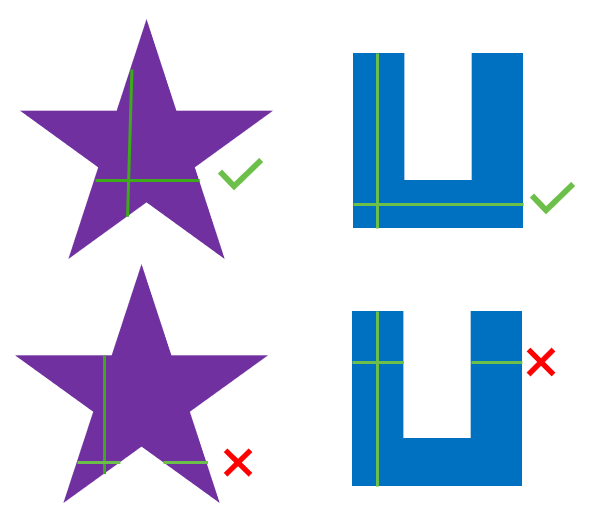

• Select a location for the seed point such that the fixed warp fiber or the fixed weft fiber does not enter and exit the ply boundary multiple times.

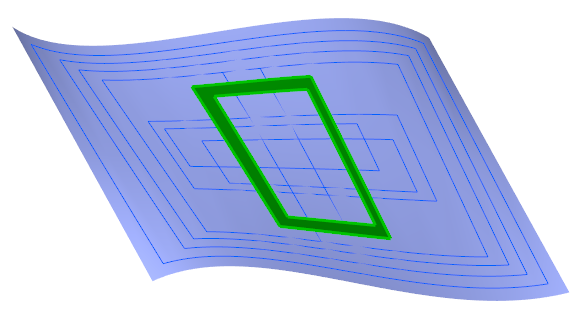

• Draping over inner loops is supported. However, you may not achieve good results in the following cases:

◦ The ply contains a large, slightly non-planar or twisted inner loop.

◦ The ply contains a small, extremely non-planar or twisted inner loop.

Good results can be achieved by moving the seed point so that the fixed warp and fixed weft fibers do not pass over the inner loop.  |

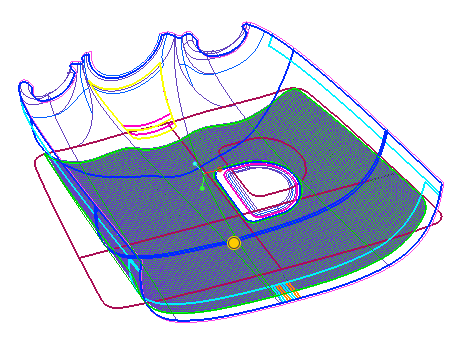

• Avoid draping a ply around a continuous shape, such as a cylindrical surface. You can drape only up to 350° around such shapes.

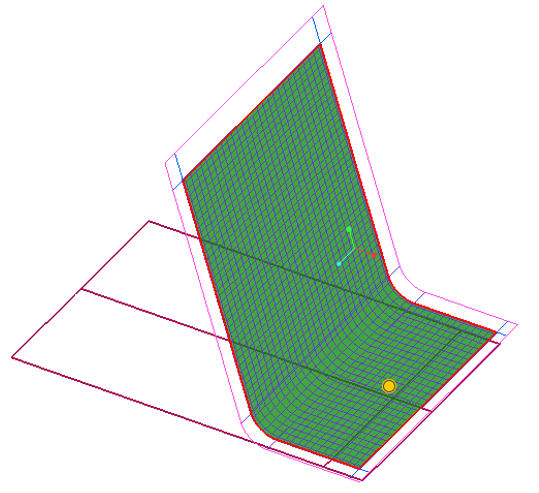

• Align the draping direction parallel or perpendicular to the areas of high curvature because when you drape a ply at an angle across an area of high curvature, such as 45° to an upstand or U-section, it may produce high shear deformations. You can align the draping direction parallel or perpendicular to the areas of high curvature.

• When a ply drops over a large stack of underlying plies or a thick core, then it can result in high shear deformations. You can use a larger step length value to reduce the modelled shear deformations.