Entering Seals

The following table describes the part parameters required for seals. This includes the following subcategories:

• Seal, Dynamic Spring

• Seal, Static, Gasket

|

Parameter

|

Type

|

Description

|

|---|---|---|

|

Meyer Hardness

|

Real (psi). Used in Ch calculation.

|

The Meyer Hardness factor in pounds per square inch (psi). Young's modulus is equivalent to Meyer's hardness for rigid material. Meyer’s hardness can be calculated using the following equation:  Where: • Pf = The load applied to the sample in pounds (lbs). • Din = The diameter of indentation of sample in inches (in). |

|

Contact Pressure

|

Real (psi). Used in Ch calculation.

|

The minimum contact pressure in psi. For ranges for common seal materials, see Contact Pressure Values. You can also calculate the minimum contact pressure using the following equation:  Where: • C = The contact pressure in psi. • FC = The force compressing seals in lbs. • ASC = The area of seals in square inches. |

|

Surface Finish

|

Real (microinches). Used in Cf calculation.

|

The surface finish in micro inches. Common values range from 0 to 100.

|

|

# Particles/Hr/GPM

|

Real (N10). Used in Cn calculation.

|

The number of particles (mg) under 10 micron per hour per GPM (N10). For more information, see Particle Quantities.

|

|

Allowable Leakage

|

Real (inches cubed/minute/Max Rated GPM). Used in Cq calculation.

|

The allowable leakage in inches cubed/minute/Max Rated GPM. The range is commonly from 0.005 to 0.1.

|

|

Actual PV

|

Real. Used in Cpv calculation.

|

Required only for the Seal, Dynamic Spring subcategory.

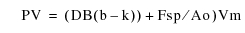

The pressure-velocity coefficient factor of the actual seal operation. The pressure velocity (PV) can be calculated using the following equation:  Where: • DP = The pressure differential across seal face in psi. • b = The seal balance; ratio of hydraulic closing area to seal face area. • Fsp = The seal spring load in lbs. • A0 = The seal face area in inches squared. • Vm = The velocity at the seal mean diameter in ft/min. |

|

Rated PV

|

Real. Used in Cpv calculation.

|

Required only for the Seal, Dynamic Spring subcategory.

The pressure-velocity coefficient factor of the original design. This indicates the effect of wear from seal face pressure and fluid velocity. For the equation, see the previous description.

|

|

Inner Seal Diameter

|

Real (in). Used in Cdl calculation.

|

Required only for the Seal, Static, Gasket subcategory.

The diameter of the inner seal in inches. Common values range from 0 to 2.

|

|

Fluid Pressure

|

Real (psi). Used in Cp calculation.

|

Required only for the Seal, Static, Gasket subcategory.

The fluid pressure in psi. Range is commonly from 0 to 9000.

|

|

Filter Size

|

Real (microns). Used in Cn calculation.

|

The system filter size in microns.

|

|

Viscosity (xE-8)

|

Real (Lb Min/Sq In * E-8). Used in Cv calculation.

|

The viscosity of the fluid. Entered values are multiplied by 1E-8 to obtain actual viscosity. Fluid viscosity changes with temperature. For more information, see Viscosity.

|

|

Temperature Rise

|

Real (Degrees C). Used in Ct calculation.

|

The temperature rise from the ambient subassembly temperature to this component. The temperature rise plus the ambient temperature is equal to the operating temperature of the device.

|

|

Rated Temperature

|

Real (Degrees C). Used in Ct calculation.

|

The maximum temperature rating specified by the manufacturer or the maximum design temperature. For more information, see Rated Temperatures.

|

|

Rated Flow Rate

|

Real (Gallons/Minute). Used in Cn calculation.

|

The maximum rated flow in gallons/minute.

|

|

[Derating Parameters]

|

---

|

For more information, see Derating Parameters.

|