The Maintenance Process

The primary goal of maintenance is to keep a component or system in operational condition. With its advanced analysis capabilities, the RBD module considers both corrective maintenance and general maintenance. Corrective maintenance is reactive, which means that it is performed after an unwanted event (failure) has occurred. General maintenance is proactive, which means that it is performed to prevent an unwanted failure event from occurring.

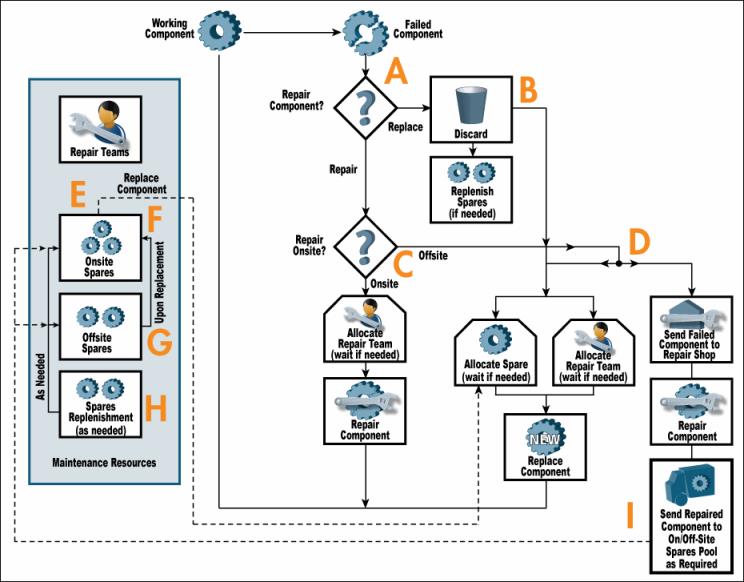

The maintenance process supported in shown in the following flowchart. The paragraphs that follow the flowchart reference the different labels (A − I) within the flowchart.

When a working component fails, it can be repaired (A) or discarded (B). If the component is repaired, the repair can be performed onsite by an allocated repair team (C) or offsite at a repair shop (D).

If a failed component cannot be repaired quickly onsite, it is probably replaced with a spare component (E). You can indicate the number of spares available both onsite (F) and offsite (G). Additionally, you can specify the costs associated with storing spares onsite and offsite as well as the costs associated with transporting spares between onsite, offsite, and repair shop locations. These values are then used in both cost and optimization calculations.

For onsite and offsite spare locations, you can indicate the level to which the quantity of spares can fall before additional spares must be ordered for replenishment (H). Once a failed component is repaired at the repair shop, it can join those in the spares pool (I).

You can optimize maintenance intervals and the number of repair resources and spares needed to achieve a variety of goals. These optimized values can then be used in all RBD calculations.

The following topics provide additional topics that further describe the maintenance process: