AGREE Allocation Method Calculations

The AGREE allocation method is proposed by the Advisory Group on Reliability of Electronic Equipment, Office of the Assistant Secretary of Defense, USA. To compute allocated failure rates, it uses the number of subsystems as a measure of complexity and an importance factor and a mission time. This method is recommended for systems with a three-level hierarchical System Tree: System, Subassembly, and Item. When both deep and shallow branches are present in the system tree, this method may not be a good fit.

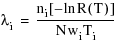

The equation for the AGREE allocation method is:

Where:

ni. = The number of subassemblies in the subsystem.

R(T) = The reliability goal.

N = The total number of all subassemblies.

wi = The importance factor.

Ti = The mission time.

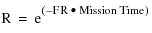

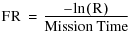

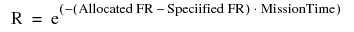

The equations for reliability (R) and failure rate (FR) follow.

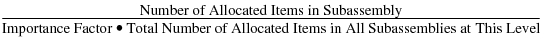

The equation for computing the weight factor is:

Note that only allocated items are included in the subassembly counts.

When the importance factors and mission times differ for the various subassemblies in the system, the sum of these failure rates is not necessarily equal to the system failure rate.

Example 1

Reliability Goal = 0.95. In this case, N = 19.

System Level 1 Subassemblies | Number of Items in Subassembly | Importance Factor | Mission Time of Subassembly |

|---|---|---|---|

A | 4 | 1.0 | 300 |

B | 8 | 0.8 | 100 |

C | 1 | 1.0 | 300 |

D | 6 | 0.9 | 100 |

For the top-most assembly (system), you enter a reliability goal of 0.95 in its Allocation pane. For more information, see AGREE Allocation Method. For subassemblies A through D, you enter respective importance factors and mission times in their Allocation panes.

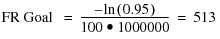

Assume that the failure rate multiplier for the System file is 1000000. This means that failure results are in failures per million hours (FPMH). Thus, everything is multiplied by 1000000. If the mission time from the Project’s Mission Profile file is 100, the equation for the failure rate goal for the system would be:

To compute the failure rates for subassemblies A, B, C, and D, the equations below are used.

Subassembly | Equation |

|---|---|

A |  |

B |  |

C |  |

D |  |

Example 2

An example follows for a subassembly with a non-allocated (specified) failure rate.

Reliability Goal = 0.95. In this case, N = 19.

System Level 1 Subassemblies | Number of Items in Subassembly | Importance Factor | Mission Time of Subassembly |

|---|---|---|---|

A | 4 | 1.0 | 300 |

B | 8 | 0.8 | 100 |

C | 1 | 1.0 | 300 |

D | 6 | 0.9 | 100 |

E, Specified FR = 250 | |||

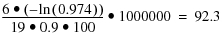

Given the same assumptions as in Example 1, the equation for the failure rate goal for this system is:

The equations follow for calculating the new reliability goal when the specified failure rate of subassembly E is included.

To compute the failure rates for subassemblies A, B, C, and D, the equations below are used. The specified failure rate for subassembly E is 250.

Subassembly | Equation |

|---|---|

A |  |

B |  |

C |  |

D |  |