Localizing Operations in a Routing Plan Context

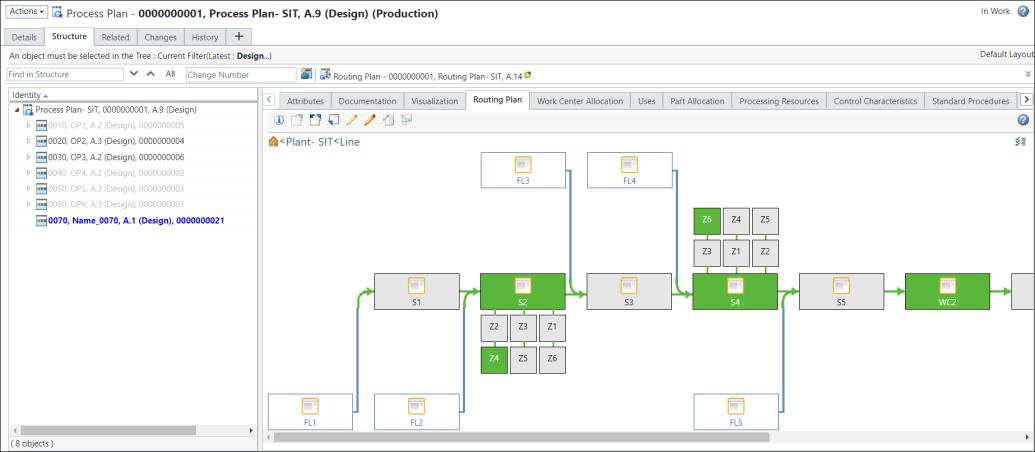

Localizing operations is a way to assign operations to a specific workstation within a plant. Localizing an operation on a station means you are instructing the system to perform or implement the particular operation on the particular workstation. As a manufacturing engineer or a plant engineer, if you have a set of operations and a set of workstations on your line, based on business considerations you will decide which operation should be performed on which workstation to achieve the optimal output of your plant. This process includes managing cost, time, and other entities. For more information, see Localizing Operations. You can localize the operations using the process plan tree structure and the Routing Plan tab. To localize, drag the operations from the process plan tree structure to the following entities in the Routing Plan tab.

• Zones and stations on the main line

• Zones and stations on the feeder line

Key Points — Localizing an Operation

• When you localize the operation on the workstation, the workstation turns green. That is, when you drag the operations from the process plan tree structure to a workstation in the Routing Plan tab, the workstation turns green.

• The most recent localized operation is highlighted in blue color in the process plan tree structure.

• You can localize an operation only on one station.

• The faded operations in the process plan tree structure indicate that the operations are already localized. Note that an already localized operation cannot be relocalized to any other station from the Process Plan Browser (PPB) tree structure.

• The available or non-faded operations in the process plan tree structure indicate that the operations are not localized. Based on your business requirements, you can use these operations for localization.

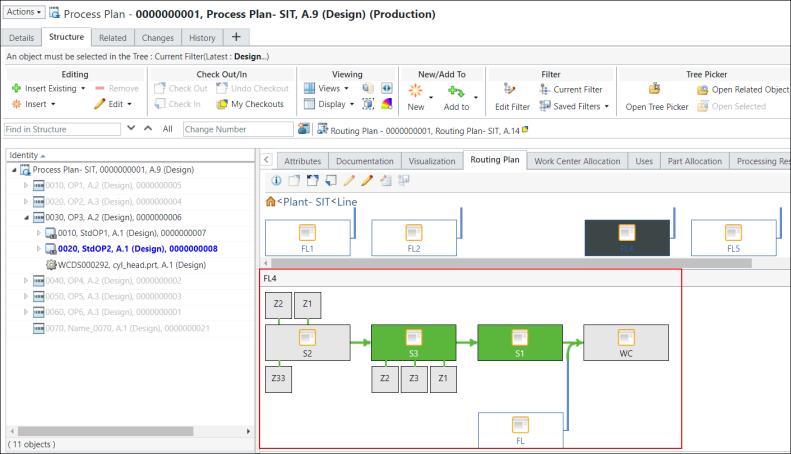

• In the Routing Plan tab, when you click a feeder line, the system displays the stations and zones associated with the feeder line in the bottom portion.

• When you localize the operation on the stations or zones, the stations or zones turn green. After selecting the station or zone, the station or zone turns black, and the system displays the following respective child items of the station or zone:

◦ Localized Operations — View a list of all localized operations.

◦ Work Centers — View a list of all work centers

◦ Skills — View a list of all skills.

◦ Tooling — View a list of all tooling.

◦ Process Materials — View a list of all process materials.

For more information, see Actions for Localized Operations.

The Skills, Tooling, and Process Materials are associated with the stations or zones. |

• The system does not allow the same operation to be localized on more than one workstation.

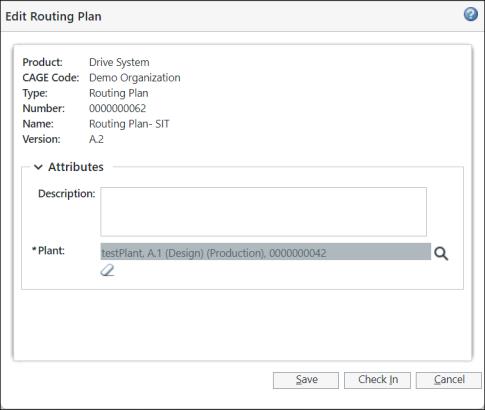

• The system checks out the routing plan when you localize an operation.

• If a zone exists under a workstation, you can localize an operation either on the workstation or zone.

• When you select one or more operations, the system decides the localized operation precedence according to the label number. You can change the precedence or sequence of a localized operation within the context of the workstation. You can re-sequence the operations by dragging or rearranging them after or before the specific operation in the Localized Operations tab within the context of the workstation. You can utilize the Uses tab in PPB to change the label numbers. For more information, see Label Numbers in Process Plans.

When you select only one operation, the system decides the precedence according to your selection, and not according to the label number.

• In the Routing Plan tab, workstations to which no operation is localized are displayed in grey. If all operations are localized and there are still workstations without a single localized operation, then it indicates that those particular workstations are not part of that particular routing plan.

• If you localize an operation on the zone, the system highlights the following entities in green:

◦ The zone

◦ The workstation associated with the zone

Relocalizing an Operation

The system allows you to relocalize an operation. Consider the following scenario, While building the manufacturing strategy to reduce time and cost, the manufacturing engineer can try various scenarios related to a routing plan. In such scenario, they may try to correct the localization of the operations and relocalize them from one station to another. The localized operations records and information are available in the Localized Operations table. To relocalize an operation, drag an operation from one station to another station. For example, you browse to the station from where you want to relocalize the operation, select that operation which you want to relocalize and drag it to the station where you want to localize it. The record of the operation is removed from the previous station and is added to the station where you dropped the localized operation.

Consider the following points related to relocalizing an operation:

• The system checks out the routing plan during the relocalization.

• The relocalization process fails if the routing plan is checked out by other users.

• The precedency of the relocalized operation may not remain the same at the target station. If the target station already has few localized operations, then the relocalized operation takes the next precedence. For example, station A2 has three localized operations under it. An operation from station A1 is dragged to station A2. The newly added operation is given fourth precedence by the system. The system allows you to change the precedence order. You can do that by rearranging the operations in the Localized Operations table. For more information, see Actions for Localized Operations.

• If you relocalize all localized operations from the station, then the station's color changes to grey, as it does not have any localized operations associated with it.

• After relocalizing, the system creates a new link. This link contains the localization information from the operation, such as time information, processing resource information, and so on.

Localizing Operations on Workstations under the Feeder Line

You can localize the operations on workstations under the feeder line. Consider the following points:

• When you click on the feeder line, the system renders the workstations and zones under it.

• You can drag and drop any operations directly on the workstations/zones under the feeder line.

• You can add, remove, and edit time values.

• Consider that a workstation is present under a feeder line. If you localize an operation to this workstation, the color of the feeder line does not change.

• You can click on the workstation to show all the localized operations. The system allows you to change the precedence order of the localized operations.