Generating and Updating the Mass mBOMs in the BOM Transformer

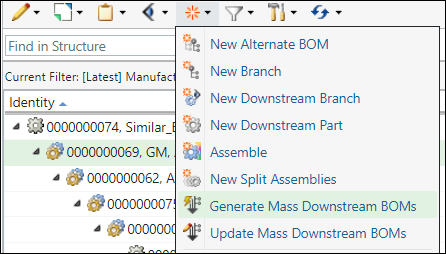

When starting any new product development process, you typically begin by reusing the existing products and then improving the original design. Similarly, for BOM variants, you want to reuse the existing parts and BOM as much as possible for a faster development and reduced cost. If you have built an mBOM from an eBOM, you can use the same mBOM to generate other mBOMs, as the differences will be insignificant. That way you can use the mBOM as a template to generate other mBOMs. The  Generate Mass Downstream BOMs and

Generate Mass Downstream BOMs and  Update Mass Downstream BOMs actions in the downstream view of the BOM Transformer enable you to generate and update mass mBOMs in the BOM Transformer.

Update Mass Downstream BOMs actions in the downstream view of the BOM Transformer enable you to generate and update mass mBOMs in the BOM Transformer.

Generate Mass Downstream BOMs and

Generate Mass Downstream BOMs and  Update Mass Downstream BOMs actions in the downstream view of the BOM Transformer enable you to generate and update mass mBOMs in the BOM Transformer.

Update Mass Downstream BOMs actions in the downstream view of the BOM Transformer enable you to generate and update mass mBOMs in the BOM Transformer.

It is essential to have knowledge about managing configurable products before using these actions. For more information, see Managing Configurable Products and the topics under it. These topics provide the following information:

• Creating variants from the configurable module

• Using variant specifications

• Using parameters when defining variant specifications

• Using options and choices.

For more information about the terminology used for the mass mBOM feature, see Terminology Used in Mass mBOMs.

For more information about the generate and update logic, see Generate and Update Logic.

Generating Mass mBOMs in the BOM Transformer

Use the  Generate Mass Downstream BOMs action to create mass mBOMs from related upstream variants or generic mBOMs. In this case, the system uses the generic mBOM as a template for generating mBOM variants. Before using the

Generate Mass Downstream BOMs action to create mass mBOMs from related upstream variants or generic mBOMs. In this case, the system uses the generic mBOM as a template for generating mBOM variants. Before using the  Generate Mass Downstream BOMs action, you ensure that the following entities are available:

Generate Mass Downstream BOMs action, you ensure that the following entities are available:

Generate Mass Downstream BOMs action to create mass mBOMs from related upstream variants or generic mBOMs. In this case, the system uses the generic mBOM as a template for generating mBOM variants. Before using the

Generate Mass Downstream BOMs action to create mass mBOMs from related upstream variants or generic mBOMs. In this case, the system uses the generic mBOM as a template for generating mBOM variants. Before using the  Generate Mass Downstream BOMs action, you ensure that the following entities are available:

Generate Mass Downstream BOMs action, you ensure that the following entities are available:• A generic eBOM

• A generic mBOM

• A variant eBOM

Refer to the following tutorials for more details:

The system generates variant mBOMs once the  Generate Mass Downstream BOMs action is completed. The system generates variant mBOMs by referring or using a generic mBOM and by using a variant specification of each E-variant.

Generate Mass Downstream BOMs action is completed. The system generates variant mBOMs by referring or using a generic mBOM and by using a variant specification of each E-variant.

Generate Mass Downstream BOMs action is completed. The system generates variant mBOMs by referring or using a generic mBOM and by using a variant specification of each E-variant.

Generate Mass Downstream BOMs action is completed. The system generates variant mBOMs by referring or using a generic mBOM and by using a variant specification of each E-variant.For more information about the terminology used for the mass mBOM feature, see Terminology Used in Mass mBOMs.

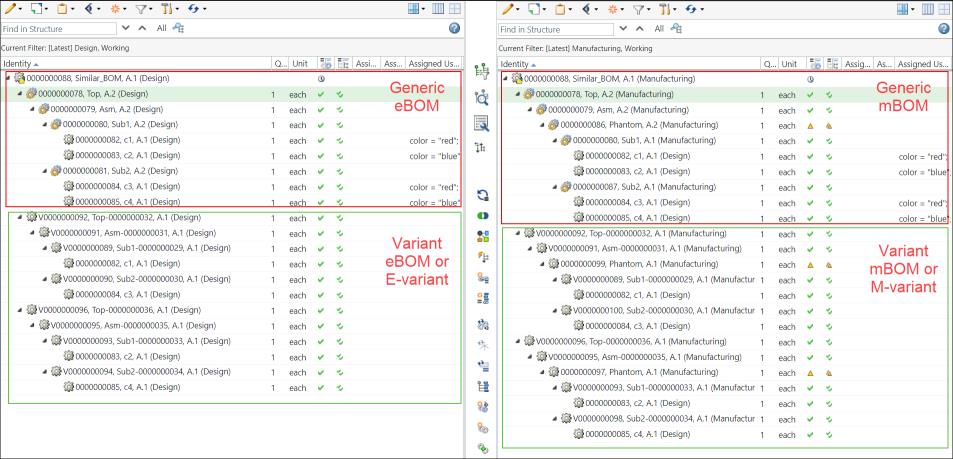

The next image shows the various entities involved in the functioning of the  Generate Mass Downstream BOMs action.

Generate Mass Downstream BOMs action.

Generate Mass Downstream BOMs action.

Generate Mass Downstream BOMs action.

This structure can contain a list of generic eBOMs, related generic mBOMs, generated variant eBOMs, and related variant mBOMs.

• The system creates links between the variant eBOMs and variant mBOMs once the  Generate Mass Downstream BOMs action is complete.

Generate Mass Downstream BOMs action is complete.

Generate Mass Downstream BOMs action is complete.

Generate Mass Downstream BOMs action is complete.• For generating variant mass mBOMs using the  Generate Mass Downstream BOMs action, the system uses variant specifications associated with all or the selected E-variants. Based on the information contained in the variant specifications, the system generates the variant mass mBOMs.

Generate Mass Downstream BOMs action, the system uses variant specifications associated with all or the selected E-variants. Based on the information contained in the variant specifications, the system generates the variant mass mBOMs.

Generate Mass Downstream BOMs action, the system uses variant specifications associated with all or the selected E-variants. Based on the information contained in the variant specifications, the system generates the variant mass mBOMs.

Generate Mass Downstream BOMs action, the system uses variant specifications associated with all or the selected E-variants. Based on the information contained in the variant specifications, the system generates the variant mass mBOMs.• For the  Generate Mass Downstream BOMs and

Generate Mass Downstream BOMs and  Update Mass Downstream BOMs actions to work, the link between the E-variant and the variant specification must always be available to the system.

Update Mass Downstream BOMs actions to work, the link between the E-variant and the variant specification must always be available to the system.

Generate Mass Downstream BOMs and

Generate Mass Downstream BOMs and  Update Mass Downstream BOMs actions to work, the link between the E-variant and the variant specification must always be available to the system.

Update Mass Downstream BOMs actions to work, the link between the E-variant and the variant specification must always be available to the system.• You can also selectively generate the variant mBOMs for a particular variant eBOM using the  Generate Downstream BOMs action available in the middle pane toolbar of the BOM Transformer. For more information, see Tutorial 3: Selectively Generating Mass mBOMs.

Generate Downstream BOMs action available in the middle pane toolbar of the BOM Transformer. For more information, see Tutorial 3: Selectively Generating Mass mBOMs.

Generate Downstream BOMs action available in the middle pane toolbar of the BOM Transformer. For more information, see Tutorial 3: Selectively Generating Mass mBOMs.

Generate Downstream BOMs action available in the middle pane toolbar of the BOM Transformer. For more information, see Tutorial 3: Selectively Generating Mass mBOMs.Updating Mass mBOMs in the BOM Transformer

Use the  Update Mass Downstream BOMs action in the downstream view to update the already generated variant mBOMs. It is recommended that you use the

Update Mass Downstream BOMs action in the downstream view to update the already generated variant mBOMs. It is recommended that you use the  Update Mass Downstream BOMs action only when the generic eBOM, generic mBOM and variant eBOMs are up to date. That is, all these entities must not be

Update Mass Downstream BOMs action only when the generic eBOM, generic mBOM and variant eBOMs are up to date. That is, all these entities must not be  out of date. Also, all entities in the upstream view, that is generic eBOM and variant eBOMs, must be in the updated state. Refer the following topics for more details:

out of date. Also, all entities in the upstream view, that is generic eBOM and variant eBOMs, must be in the updated state. Refer the following topics for more details:

Update Mass Downstream BOMs action in the downstream view to update the already generated variant mBOMs. It is recommended that you use the

Update Mass Downstream BOMs action in the downstream view to update the already generated variant mBOMs. It is recommended that you use the  Update Mass Downstream BOMs action only when the generic eBOM, generic mBOM and variant eBOMs are up to date. That is, all these entities must not be

Update Mass Downstream BOMs action only when the generic eBOM, generic mBOM and variant eBOMs are up to date. That is, all these entities must not be You can also selectively update the variant mBOMs. For more information, see the Additional Information section in Tutorial 1: Updating Mass mBOMs.

Key Points

• A generated process plan is a variant extracted from the generic process plan. The structure of a generated process plan is a combination of operations, associations, and allocations from the generic process plan and variant mBOM that is filtered based on a variant specification or part tags. A generic process plan is associated with a generic mBOM and includes configurable operations to support the ability to create multiple generated process plans. For more information, see Generated Process Plans.

• The behavior of the  Generate Mass Downstream BOMs and

Generate Mass Downstream BOMs and  Update Mass Downstream BOMs actions depend on the value set in the Life Cycle States to Revise an Object When Updating its Structure preference. For more information on this preference, see Preferences in MPMLink.

Update Mass Downstream BOMs actions depend on the value set in the Life Cycle States to Revise an Object When Updating its Structure preference. For more information on this preference, see Preferences in MPMLink.

Generate Mass Downstream BOMs and

Generate Mass Downstream BOMs and  Update Mass Downstream BOMs actions depend on the value set in the Life Cycle States to Revise an Object When Updating its Structure preference. For more information on this preference, see Preferences in MPMLink.

Update Mass Downstream BOMs actions depend on the value set in the Life Cycle States to Revise an Object When Updating its Structure preference. For more information on this preference, see Preferences in MPMLink.• For generating variant mass mBOMs using the  Generate Mass Downstream BOMs action, the system uses variant specifications associated with related E-variants. Based on the information contained in the variant specifications, the system generates the variant mass mBOMs.

Generate Mass Downstream BOMs action, the system uses variant specifications associated with related E-variants. Based on the information contained in the variant specifications, the system generates the variant mass mBOMs.

Generate Mass Downstream BOMs action, the system uses variant specifications associated with related E-variants. Based on the information contained in the variant specifications, the system generates the variant mass mBOMs.

Generate Mass Downstream BOMs action, the system uses variant specifications associated with related E-variants. Based on the information contained in the variant specifications, the system generates the variant mass mBOMs.