Example: Rework Ratio KPI

This example creates a new KPI named Rework Ratio (ISO_22400). The rework ratio is the relationship between the rework quantity (RQ) and produced quantity (PQ) for a work unit, product, production order, or defect type:

RQ/PQ

The rework quantity (RQ) KPI element is created as part of this example.

1. Create a new Thing Shape named ACME_CORP.KPI.ReworkRatioThingShape with the following properties:

◦ ReworkRatio_currentValue,with Base Type=Number

◦ ReworkRatio_lastCalculatedTime, with Base Type=DateTime

◦ ReworkRatio_unitOfMeasure, with Base Type=String

Ensure that the Persistent checkbox is selected for each of these properties.

2. Implement the following services on the ACME_CORP.KPI.ReworkRatioThingShape Thing Shape:

◦ Get_ReworkRatio_CurrentValue

◦ Get_ReworkRatio_ThresholdValues

◦ Get_ReworkRatio_Trend

◦ ReworkRatio_Calculate

◦ Set_ReworkRatio_CurrentValue

3. On the Thing Template of each equipment type for which this KPI is to be calculated, override the GetKPINames service. Add the ACME_CORP.KPI.ReworkRatioThingShape Thing Shape, as in the following example code:

var kpiInfoJSON = new Object();

// JSON of KPI information we want to test if they are implemented on "me"

// For custom KPI, please add into this JSON and following given format

// Warning the order is important

kpiInfoJSON.kpiInfoArray = [

{kpiThingShapeName: 'PTC.SCA.SCO.AvailabilityThingShape', kpiName: 'Availability'},

{kpiThingShapeName: 'PTC.SCA.SCO.QualityRatioThingShape', kpiName: 'QualityRatio'},

{kpiThingShapeName: 'PTC.SCA.SCO.EffectivenessThingShape', kpiName: 'Effectiveness'},

{kpiThingShapeName: 'PTC.SCA.SCO.OEEThingShape', kpiName: 'OEE'},

{kpiThingShapeName: 'ACME_CORP.KPI.ReworkRatioThingShape', kpiName: 'ReworkRatio'}

];

var result = Things["PTC.SCA.SCO.DefaultKPIManager"].GetImplementedKPIsOnThing({

thingName: me.name,

kpiInfo: kpiInfoJSON

});

// JSON of KPI information we want to test if they are implemented on "me"

// For custom KPI, please add into this JSON and following given format

// Warning the order is important

kpiInfoJSON.kpiInfoArray = [

{kpiThingShapeName: 'PTC.SCA.SCO.AvailabilityThingShape', kpiName: 'Availability'},

{kpiThingShapeName: 'PTC.SCA.SCO.QualityRatioThingShape', kpiName: 'QualityRatio'},

{kpiThingShapeName: 'PTC.SCA.SCO.EffectivenessThingShape', kpiName: 'Effectiveness'},

{kpiThingShapeName: 'PTC.SCA.SCO.OEEThingShape', kpiName: 'OEE'},

{kpiThingShapeName: 'ACME_CORP.KPI.ReworkRatioThingShape', kpiName: 'ReworkRatio'}

];

var result = Things["PTC.SCA.SCO.DefaultKPIManager"].GetImplementedKPIsOnThing({

thingName: me.name,

kpiInfo: kpiInfoJSON

});

4. Declare the thresholds for the Rework Ratio KPI. On the Configuration page of the PTC.SCA.SCO.DefaultKPIManager Thing, add a new configuration table.

a. On the PTC.SCA.SCO.DefaultKPIManager Thing, add a configuration table with the following values:

▪ Table Name—ReworkRatioThresholdValues

▪ Data Shape—PTC.SCA.SCO.KPIThresholdValues

▪ Allow Multiple Rows—Ensure that this checkbox is selected.

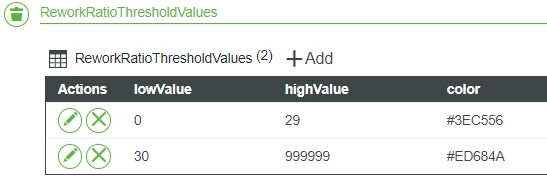

b. Add rows to the ReworkRatioThresholdValues configuration table for the desired value ranges, similar to the following image:

5. Define the rework quantity (RQ) KPI element.

a. Create a property on the ACME_CORP.KPI.ReworkRatioThingShape Thing Shape named reworkQuantity_RQ, with a Base Type of Number, and the Persistent checkbox selected.

b. Create a new service on the ACME_CORP.KPI.ReworkRatioThingShape Thing Shape named reworkQuantity_RQ_Calculate with the following code:

function isUndefinedOrNull(value){

return (value === null || typeof(value) === "undefined" );

}

result = me.reworkQuantity_RQ;

//Register first value to cache

me.RegisterValueToKPICache({

key: "reworkQuantity_RQ_firstValue" /* STRING */,

value: result, /* NUMBER */

TimeInfo : TimeInfo

});

return (value === null || typeof(value) === "undefined" );

}

result = me.reworkQuantity_RQ;

//Register first value to cache

me.RegisterValueToKPICache({

key: "reworkQuantity_RQ_firstValue" /* STRING */,

value: result, /* NUMBER */

TimeInfo : TimeInfo

});

c. On the Thing Template of each equipment type for which this KPI is to be calculated, override the GetKPIElementNames service. Add the new property to the list. For example:

result = "actualProductionTime_APT,goodQuantity_GQ,plannedBusyTime_PBT,plannedRunTimePerItem_PRI,producedQuantity_PQ,reworkQuantity_RQ";

d. Update the ReworkRatio_Calculate service created in step 2 to include the new rework quantity (RQ) KPI element. For example:

var customLogger = logger.getLoggerContext().getLogger(logger.getName()+".com.ptc.sca.sco.KPICalculation.ReworkRatio");

var reworkRatio = me.reworkQuantity_RQ;

var producedQuantity = me.producedQuantity_PQ;

if (TimeInfo.getRowCount() > 0){

var row = TimeInfo.getRow(0);

var startTime = row.StartTimeDate;

var generatedID= row.GeneratedID;

// result from service GetKPIElementStartValue: INFOTABLE dataShape: "PTC.SCA.SCO.KPIElementValue"

var reworkQuantity_RQ_firstValue = me.GetKPICacheValue({

generatedID: generatedID/* STRING */,

name: "reworkQuantity_RQ_firstValue" /* STRING */

});

var producedQuantity_PQ_firstValue = me.GetKPICacheValue({

generatedID: generatedID/* STRING */,

name: "producedQuantity_PQ_firstValue" /* STRING */

});

var producedTotalQuantity = 0;

var producedReworkQuantity = 0;

if ( (typeof producedQuantity_PQ_firstValue !== 'undefined') && (typeof reworkQuantity_RQ_firstValue !== 'undefined') ){

producedTotalQuantity = (producedQuantity - producedQuantity_PQ_firstValue);

producedReworkQuantity = (reworkRatio - reworkQuantity_RQ_firstValue);

if ( producedTotalQuantity === 0 ){

// Until items are produced, rework ratio cannot be measured and will default to 1

// with producedReworkQuantity greater than 0, then the service will return 0.

reworkRatio = producedReworkQuantity > 0 ? 0: 1;

}

else{

reworkRatio = producedReworkQuantity / producedTotalQuantity;

}

customLogger.debug("ReworkRatio_Calculate: produced quantity value when time info started - last produced quantity :"+ producedQuantity_PQ_firstValue+"-"+producedQuantity);

customLogger.debug("ReworkRatio_Calculate: rework quantity value when time info started - last good quantity: "+ reworkQuantity_RQ_firstValue+"-"+reworkRatio);

customLogger.debug("ReworkRatio_Calculate: produced Rework Quantity / produced total quantity = quality ratio: " +producedReworkQuantity+ " / " + producedTotalQuantity + " = " + reworkRatio);

}

else{

customLogger.warn("ReworkRatio_Calculate for "+me.name+" could not retrieve the good quantity or produced quantity at the start of the time info.");

}

}

else{

customLogger.warn("ReworkRatio_Calculate for "+me.name+" could not retrieve the current time info. ReworkRatio = 0.");

}

var result = reworkRatio;

me.Set_ReworkRatio_CurrentValue({

value: result

});

var now = new Date();

me.ReworkRatio_lastCalculatedTime = now;

var reworkRatio = me.reworkQuantity_RQ;

var producedQuantity = me.producedQuantity_PQ;

if (TimeInfo.getRowCount() > 0){

var row = TimeInfo.getRow(0);

var startTime = row.StartTimeDate;

var generatedID= row.GeneratedID;

// result from service GetKPIElementStartValue: INFOTABLE dataShape: "PTC.SCA.SCO.KPIElementValue"

var reworkQuantity_RQ_firstValue = me.GetKPICacheValue({

generatedID: generatedID/* STRING */,

name: "reworkQuantity_RQ_firstValue" /* STRING */

});

var producedQuantity_PQ_firstValue = me.GetKPICacheValue({

generatedID: generatedID/* STRING */,

name: "producedQuantity_PQ_firstValue" /* STRING */

});

var producedTotalQuantity = 0;

var producedReworkQuantity = 0;

if ( (typeof producedQuantity_PQ_firstValue !== 'undefined') && (typeof reworkQuantity_RQ_firstValue !== 'undefined') ){

producedTotalQuantity = (producedQuantity - producedQuantity_PQ_firstValue);

producedReworkQuantity = (reworkRatio - reworkQuantity_RQ_firstValue);

if ( producedTotalQuantity === 0 ){

// Until items are produced, rework ratio cannot be measured and will default to 1

// with producedReworkQuantity greater than 0, then the service will return 0.

reworkRatio = producedReworkQuantity > 0 ? 0: 1;

}

else{

reworkRatio = producedReworkQuantity / producedTotalQuantity;

}

customLogger.debug("ReworkRatio_Calculate: produced quantity value when time info started - last produced quantity :"+ producedQuantity_PQ_firstValue+"-"+producedQuantity);

customLogger.debug("ReworkRatio_Calculate: rework quantity value when time info started - last good quantity: "+ reworkQuantity_RQ_firstValue+"-"+reworkRatio);

customLogger.debug("ReworkRatio_Calculate: produced Rework Quantity / produced total quantity = quality ratio: " +producedReworkQuantity+ " / " + producedTotalQuantity + " = " + reworkRatio);

}

else{

customLogger.warn("ReworkRatio_Calculate for "+me.name+" could not retrieve the good quantity or produced quantity at the start of the time info.");

}

}

else{

customLogger.warn("ReworkRatio_Calculate for "+me.name+" could not retrieve the current time info. ReworkRatio = 0.");

}

var result = reworkRatio;

me.Set_ReworkRatio_CurrentValue({

value: result

});

var now = new Date();

me.ReworkRatio_lastCalculatedTime = now;