•  Edge Rip—Tears the sheet metal along an edge. You can define edge treatment for the ripped edges.

Edge Rip—Tears the sheet metal along an edge. You can define edge treatment for the ripped edges.

Edge Rip—Tears the sheet metal along an edge. You can define edge treatment for the ripped edges.

Edge Rip—Tears the sheet metal along an edge. You can define edge treatment for the ripped edges. Edge Rip—Tears the sheet metal along an edge. You can define edge treatment for the ripped edges.

Edge Rip—Tears the sheet metal along an edge. You can define edge treatment for the ripped edges.

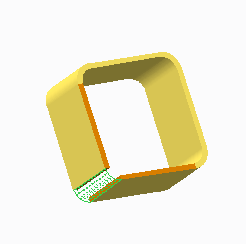

Surface Rip—Cuts out an entire surface patch from the model and removes volume from the model.

Surface Rip—Cuts out an entire surface patch from the model and removes volume from the model.

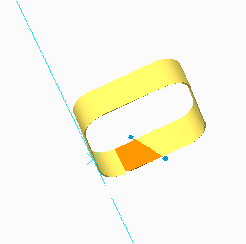

Sketched Rip—Tears the sheet metal along a sketched line. You can exclude surfaces to protect them from the rip.

Sketched Rip—Tears the sheet metal along a sketched line. You can exclude surfaces to protect them from the rip.

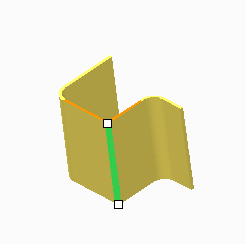

Rip Connect—Tears the sheet metal between two datum points or vertices, or a combination of both.

Rip Connect—Tears the sheet metal between two datum points or vertices, or a combination of both.