Floor 5 Axis Finish Sequences: Specific Scenarios

The following are some specific scenarios that you may encounter when using  Floor 5 Axis Finish.

Floor 5 Axis Finish.

Floor 5 Axis Finish.

Floor 5 Axis Finish.Scenario 1—Toolpath is not generated and an error message is displayed

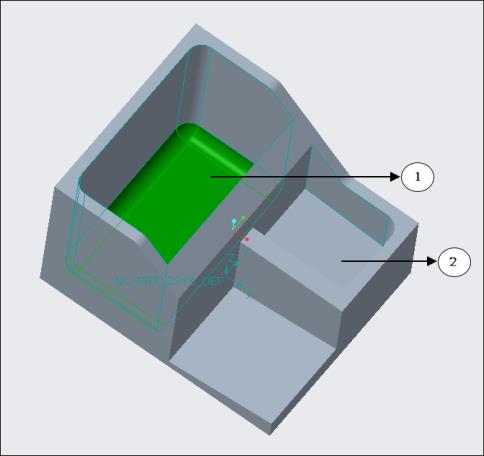

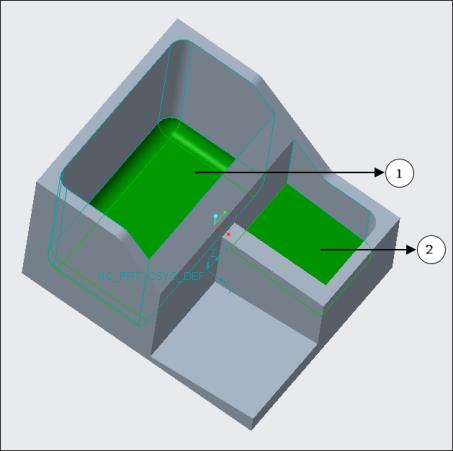

No toolpath is generated if the wall surfaces are joined together and one wall surface does not have a corresponding floor surface. For example:

1. First pocket with defined floor surfaces

2. Second pocket without defined floor surface

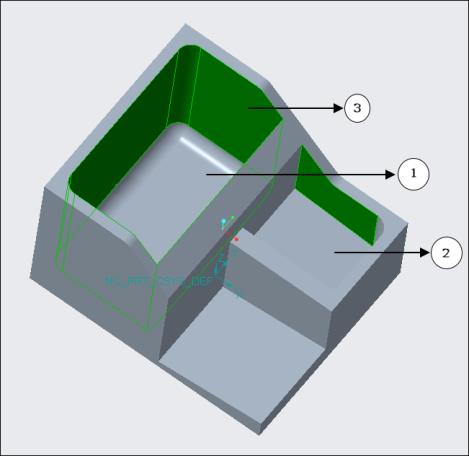

1. First pocket

2. Second pocket

3. Defined wall surfaces

To generate the toolpath on floor surfaces of both the pockets, select the floor surface corresponding to the wall surface of the second pocket. For example:

1. First pocket with defined floor surfaces.

2. Second pocket with defined floor surface.

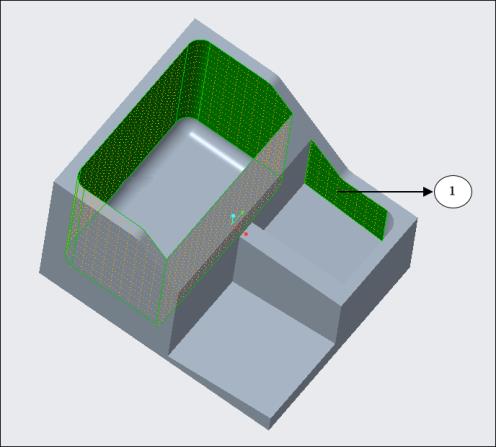

To generate the toolpath only on the floor surfaces of the first pocket, use mill surfaces in the wall surface collector, copy all required surfaces, and then exclude the extra contour. This ensures that the wall surface, which does not have a corresponding floor surface, is removed. For example:

1. Extra surface contour excluded

Scenario 2—Toolpath gets generated only in one pocket when using the Longest edge input option

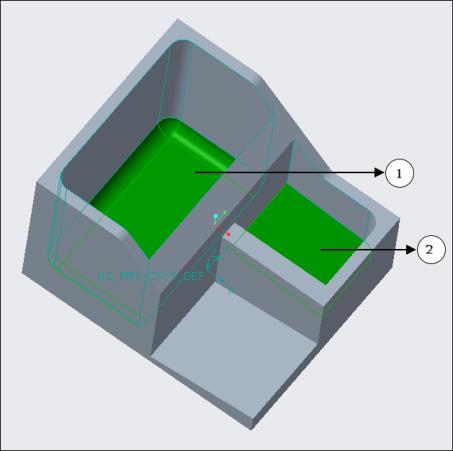

If you select floor surfaces from multiple pockets and use the Longest edge input option, then sometimes it is difficult to obtain automatic guide curves. Hence, toolpath gets generated in one pocket only. For example:

1. First pocket with defined floor surfaces.

2. Second pocket with defined floor surface.

For generating toolpath in both pockets, use the User defined input option instead of the Longest edge input option and then select the required guide curves manually.