To Define Plug or Slot Weld Options

You must be on the Plug/Slot Weld tab to perform this procedure.

1. Click the Options tab.

2. To set how the weld is represented, under Weld geometry type, select Surface, Light, or Solid.

3. Select a predefined welding material from the Weld material list, or click Define to open the Weld Materials dialog box and define a new welding material.

4. Select a predefined welding process from the Weld process list, or click Define to open the Weld Processes dialog box and define a new welding process.

5. To define the weld as a field weld, select the

Field weld

Field weld check box.

6. To define a weld finish, choose one of the following options:

◦ ANSI: Select an option from the Finish list: None, Chipping, Grinding, Hammering, Machining, Rolling, or Unspecified.

◦ ISO: Select the

Finish

Finish check box to set the finish to ISO standards.

7. Select an option from the Contour list: None, Flat, Convex, or Concave.

8. To show the sequence ID number in the welding symbol tail, select the Display sequence ID check box. To hide the sequence ID number, clear the check box.

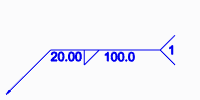

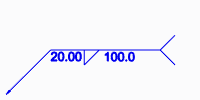

Show sequence ID | Hide sequence ID |

| |

9. To keep the weld ID number the same regardless of subsequent actions, select the Keep ID in sequence check box.

Field weld check box.

Field weld check box. Field weld check box.

Field weld check box. Field weld check box.

Field weld check box. Finish check box to set the finish to ISO standards.

Finish check box to set the finish to ISO standards.