|

|

|

|

|

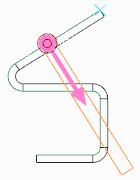

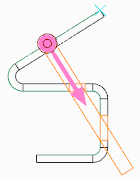

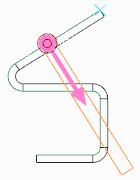

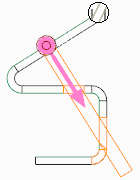

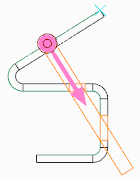

Solid cut

|

Cut normal to both driving and offset surfaces

|

Cut normal to driving surface

|

Cut normal to offset surface

|

|

|

|

|

|

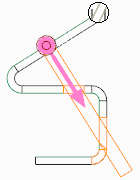

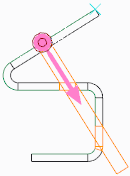

Solid cut

|

Cut normal to both driving and offset surfaces

|

Cut normal to driving surface

|

Cut normal to offset surface

|

|

|

|

|

|

|

|

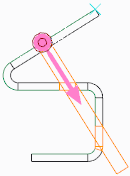

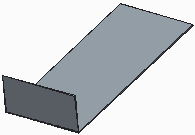

Original bent wall

|

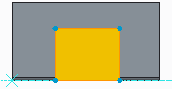

Blind cut sketch

|

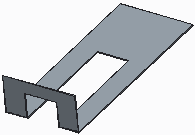

Blind cut

|

|

|

• A cut cannot cross two bend lines.

• A cut can never be made on an edge.

• Cutting on angles or bend areas might require a larger dimension scale for proper clearance.

• Cuts can be used to create notch and punch UDFs.

|