|

Rule

|

Description

|

Default Value

|

Example

|

|

MIN_DIST_BTWN_CUTS

|

Checks the distance between two cuts or punches

|

5*T

|

1. 2T or 3T or Greater 2. Stock Thickness (T) |

|

MIN_CUT_TO_BOUND

|

Checks the distance between a part edge and a cut or punch.

|

2*T

|

|

|

MIN_CUT_TO_BEND

|

Checks the distance between a bend-line and a cut or punch.

|

2.5 *T + R

|

Where, H = Distance between the lowest edge and the hole T = Sheet metal thickness R = Bend radius Min H = 1.5*T+R |

|

MIN_WALL_HEIGHT

|

Checks the minimum bend height of formed walls.

|

1.5 * T + R

|

|

|

MIN_SLOT_TAB_WIDTH

|

Checks the minimum width of the slot.

|

T

|

1. Slot Height 2. Slot Width (T) |

|

MIN_SLOT_TAB_LENGTH

|

Checks the minimum length of the slot.

|

0.7

|

|

|

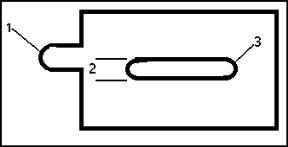

MIN_LASER_DIM

|

For outer contour—checks if it has an arc with a diameter smaller than this value.

For inner contour—checks if it has an arc with a diameter smaller than this value and checks the distance between two parallel edges.

|

1.5*T

|

1. Outer contour arc 2. distance between 2 parallel lines 3. Inner contour arc |