System Reliability Model

A reliability model for a group of items is derived by combining the reliabilities of the individual items according to set rules for combining probabilities. The two most common groups of items are:

• Series configuration. All items must operate successfully for the group to be successful. Here the group reliability is the product of the reliabilities of the individual items if they are independent, that is:

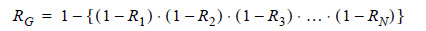

• Parallel (Active) Redundancy configuration. In its simplest form, all items must fail for the group to fail. Here, the group reliability is equal to one minus the product of the unreliability of individual blocks if they are independent, that is:

Further expressions that can be used for other configurations (including M/N and Standby Redundancy) are given later in this chapter.

To construct a system reliability model, the RBDs must be studied and the reliabilities of individual blocks combined according to the appropriate rules. This is straightforward when the blocks are independent and in a series or simple redundancy configuration. For more complex systems, however, it is generally better to sub-divide the system into convenient areas that can be evaluated separately and then brought together to provide the system reliability. This is particularly so when blocks are in more complex redundancy configurations because these must be solved by progressive re-grouping, which allows standard expressions to be used. A simple example of the way in which this may be done is shown in Figure 4-2.

Common rules for combining reliabilities follow:

• When preparing an RBD, it is important to be aware of common shared items. A common example is shown on the next page.

• When preparing an RBD, the lowest level block would normally be associated with the system’s maintenance philosophy, i.e., those items that are replaced during maintenance.