Failure with Periodic Inspection

System reliability and availability are improved if the system is maintained periodically (preventive maintenance). It is a common practice to assume that the system is as good as new immediately after preventive maintenance has been performed. In most systems, the time spent on periodic inspection and maintenance is much less than the periodic inspection interval; consequently, it is a common practice to assume that the time is negligible.

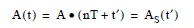

The availability at time t is given by:

Where:

As(t’)=The system availability at time t after the last periodic maintenance.

The function AS(x) represents the availability of the system at time x when there is no inspection. The time t’ is always less than the time of periodic inspection interval, T. Therefore, the time t’ is expressed as t = nT + t’, where n is the number of periodic inspections during time t’; hence, n is always zero or a positive integer.

System reliability of a periodically maintained system, R(t), is given by:

Where:

Rs(t’)=The system reliability over time t’ after the last periodic maintenance.

The function RS(x) represents the reliability of the system over time x when there is no inspection. Hence, RS(T) is the reliability of the system over a mission time T, that is, over an inspection interval.

When the inspection/maintenance time is negligible and the system is as good as new after maintenance, the reliability and availability of a periodically maintained system (or event in case of fault tree) is higher than or equal to the reliability and availability of the same system without periodic inspection. |