Reliability Prediction Basics

Reliability predictions fall into two categories:

• Parts count–Reliability prediction analyses carried out during the concept stages of a project when exact numbers and types of components are not known.

• Parts stress–Reliability prediction analyses carried out later in a project when parts lists are available and the results of component stress analyses are becoming available.

Reliability, R, has already been defined as the characteristic of an item expressed by a probability that it will perform a required function under stated conditions for a stated period of time. R is therefore a probability of failure, in that an item will operate for a stated period of time and then fail.

Now, assume the following:

• The item under consideration is a series system, i.e., the failure of one component will cause system failure.

• Each component failure is totally independent of another.

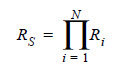

Then, from the Product Rule described on page 2-22, the reliability of that RS system, RS, will be given by:

Where RI is the reliability of each of its constituent components.

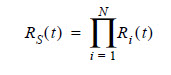

Now, introducing the time factor t:

Where:

RS(t)=The probability that the system will not fail before time t.

RI(t)=The probability that the th component of the system will not fail before time t.

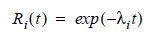

Finally, assuming that the reliability of each component,RI(t) , is exponentially (randomly) distributed with a constant failure rate of λI, then:

Therefore, the system reliability will be:

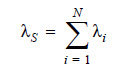

In general, a reliability prediction considers the impact of each component on the overall design in order to determine the reliability of the overall product. This is achieved by summing the failure rates of all the constituent parts of that design. This includes all components, including connectors, interconnections (solder/crimp/ welded joints, etc.) and printed circuit cards.

Hence:

Where:

λS= The system failure rate.

λI= The failure rate of each of the independent components in the system.

The failure rate model for a component for an operational mode is:

Where:

λp= The predicted failure rate of the particular component under stated environmental, temperature and electrical stress conditions.

λB= The operational base failure rate of the component.

KpE= The environmental factor for the operational environment of the component.

KS= The temperature and electrical stress factor for the component.

When an item comprises components in series, the predicted failure rate (λp) of the item can be obtained by summing the predicted failure rates of the individual components. Thus, the predicted operational failure rate of an item is given by: