|

|

Since theWindchill ESI services use the standard Windchill PDMLink log4 based logging mechanism, the information in the following sections applies to the EAI software components only.

|

|

|

Since theWindchill ESI services use the standard Windchill PDMLink log4 based logging mechanism, the information in the following sections applies to the EAI software components only.

|

|

|

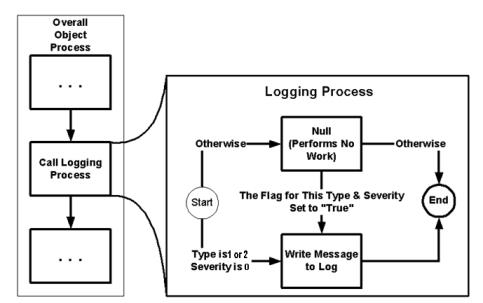

Logging can be extended to other key milestones through customization.

|

|

|

To control the size and roll-over of these log files, you can modify the values of the Max Log Files (default = 10) and Max Log File Size (default = 1000 KB) parameters. For further information, refer to the Process Engine section of the Deployment Palette chapter in the TIBCO BusinessWorks Palette Reference.

|

|

Field

|

Length

|

Description

|

|

Transaction Number

|

200

|

TheWindchill ESI transaction number that is being processed.

|

|

Target

|

25

|

Uniquely identifies the target where the object is being published and has the following format:

<Destination>,<TargetID>

where:

<Destination> exists as a child of the <Transaction element in the Windchill ESI response. It takes a value of the form <SAP System ID> . <SAP Client> where SAP System ID and SAP Client are mandatory parameters that are provided while creating an SAP type distribution target in Windchill.

<Target ID> takes a value of the form <TargetNumber>:<Plant>.

where:

<Target Number> is the number attribute on the ESITarget object representing the distribution target in Windchill and <Plant> is the plant name associated with the SAP destination. < Plant> will have an empty value if the distribution target represents a “No Plant” destination.

For example:

The following Target indicates an object being published to plant 1100 of SAP system PTCPROD, client 800 and represented by an ESITarget object having the number PTC_1:

PTCPROD.800,PTC_1:1100

A Target that is not plant-specific might look like this:

PTCPROD.800,PTC_1

|

|

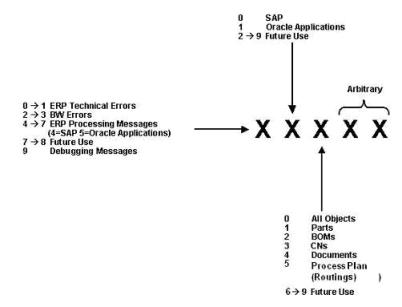

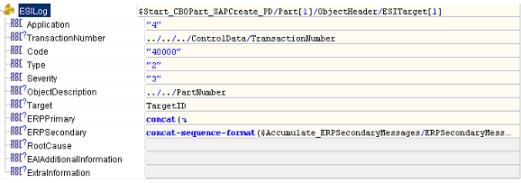

Application

|

1

|

Identifies the application that originated the message. For further details, see the Application section.

|

|

Type

|

1

|

Indicates the type of message. For further details, see the Type section.

|

|

Severity

|

1

|

Indicates the severity level of the message. For further details, see the Severity section.

|

|

Message Code

|

5

|

Unique message code identifier, used as the cross reference key to the appropriate localized message text. This field is hard-coded by the developer or a customizer when invoking the Logging Service. For further details, see the Message Code section.

|

|

EAI Primary Message Text

|

Descriptive text such as a message description (corresponds to the Message Code).

This text is localized based on the ESILog/Locale global variable. For more information see Internationalization Considerations.

For example: Received ESI Response.

|

|

|

Descriptive Text

|

Any descriptive text. For example: Object Number.

|

|

|

Root Cause Analysis Message

|

Text describing possible root cause of error, or where user may find more information about the error.

This text is localized based on the ESILog/Locale global variable. For more information see Internationalization Considerations.

The logging of this information is enabled via a global variable ESILog/RootCause. See the Logging Flags section for more details.

For example: "For more information regarding this error, please refer to the SAP Application Log (transaction SLG1)"

|

|

|

ERP Primary Message

|

300

|

If applicable, this is the primary API return message from the ERP system. For SAP distribution targets, this includes the following SAP message parameters, delimited by colons, with leading and trailing spaces removed:

• Type (usually A, E, S, I, W, or X)

• ID

• Number

• Text

This text is not localized. For more information see Internationalization Considerations.

The logging of this information is enabled via a global variable ESILog/ERPPrimary. See the Logging Flags section for more details. Since this information applies to different message types and severities, it may be repeated several times in the log.

For example:

S:MM:356:The material GS_700_IB4D has been created or extended

|

|

ERP Secondary Message

|

300

|

If applicable, the secondary API return message is sent from the ERP system. For SAP distribution targets, this includes the following SAP message parameters, delimited by colons, with leading and trailing spaces removed:

• Type (usually A, E, S, I, W, or X)

• ID

• Number

• Text

Each secondary information entry is delimited by semicolons

This text is not localized. For more information see Internationalization Considerations.

The logging of this information is enabled via a global variable ESILog/ERPSecondary. See the Logging Flags section for further details. Since this information applies to different message types and severities, it may be repeated several times in the log.

For example:

H:MK:102:Trying to create: GS_700_IB4D 1200; S:M3:800:Material GS_700_IB4D created; H:MK:103:Trying to change: GS_700_IB4D 1200; S:M3:810:No changes made

|

|

EAI Additional Information

|

2500

|

Any pertinent information from EAI components (non-ERP). This text is not localized. For more information see Internationalization Considerations. Since this information applies to different message types and severities, it may be repeated several times in the log.

For example, in the case of an error, this field might contain a stack trace.

|

|

Extra Information

|

2500

|

Additional field for customization.

|

|

Application Number

|

Description

|

|

1

|

TIBCO BusinessWorks.

|

|

2

|

Windchill PDMLink.

|

|

3

|

TIBCO EMS.

|

|

4

|

TIBCO Adapter for SAP.

|

|

5

|

TIBCO Adapter for Oracle Applications.

|

|

6+

|

Reserved for future use.

|

|

Type Value

|

Message Type

|

Description

|

|

1

|

Functional

|

Provides status information on the processing of the business objects between Windchill and the Windchill ESI business logic or between the Windchill ESI business logic and the distribution target. For example, creating parts or changing BOMs.

|

|

2

|

Technical

|

Provides status information relating to technical aspects of processing. For example, failed to parse response message.

|

|

Severity Field Value

|

Severity Type

|

Description

|

Action Required by Administrator

|

|

0

|

Fatal

|

Indicates a failure occurred and that the EAI components have stopped processing.

|

Yes. Requires immediate attention from an EAI systems administrator.

|

|

1

|

Error

|

Indicates that a non-fatal error has occurred. The EAI components continue processing.

|

Yes. May require EAI systems administrator attention in the case of technical errors. May require attention from aWindchill PDMLink user for functional errors.

|

|

2

|

Warning

|

Indicates that an important or significant condition occurred but did not cause the Windchill ESIbusiness logic to stop abnormally.

|

Action sometimes required through standardWindchill PDMLink tools.

|

|

3

|

Success

|

Indicates that desired action was completed successfully.

|

None

|

|

4

|

Informational

|

Indicates that a normal processing step was performed.

|

None

|

|

9

|

Debug

|

Intended to track the progress of the BusinessWorks flow for debugging purposes.

|

None.

|

Flag | Description |

ESILog/Functional_Debug | Enables logging of messages that are type functional and severity debug. |

ESILog/Functional_Informational | Enables logging of messages that are type functional and severity informational. |

ESILog/Functional_Success | Enables logging of messages that are type functional and severity success. |

ESILog/Functional_Warning | Enables logging of messages that are type functional and severity warning. |

ESILog/Functional_Error | Enables logging of messages that are type functional and severity error. |

ESILog/Technical_Debug | Enables logging of messages that are type technical and severity debug. |

ESILog/Technical_Informational | Enables logging of messages that are type technical and severity informational. |

ESILog/Technical_Success | Enables logging of messages that are type technical and severity success. |

ESILog/Technical_Warning | Enables logging of messages that are type technical and severity warning. |

ESILog/Technical_Error | Enables logging of messages that are type technical and severity error. |

Flag | Description |

ESILog/ERPPrimary | Enables logging of ERP primary messages. For more information, see the Components of a Log Entry section. |

ESILog/ERPSecondary | Enables logging of ERP secondary messages. For more information, see the Components of a Log Entry section. |

ESILog /RootCause | Enables logging of root cause messages. For more information, see the Components of a Log Entry section. |

Field | Description |

EAI Primary Message | Text generated by EAI software components that describes the object/action/status of the subtransaction. This text is localized based on the locale (from the com_infoengine_locale property) of the data in the Windchill ESI Response. For more information see Internationalization Considerations or the Implementing Windchill ESI. For example: "Successfully created part in SAP." |

EAI Secondary Message | Text generated by EAI software components that tells the user of any warning or functional decision messages. This text is localized based on the locale (from the com_infoengine_locale property) of the data in the Windchill ESI Response (For more information see Internationalization Considerations or theImplementing Windchill ESI for more details). Including this information in the message is enabled via a global variable ESIMessaging/EAISecondary. For more information, see the Return Messaging Flags section. For example: "Creating document version failed but assuming functional success." |

Root Cause Analysis Message | Text generated by EAI software components that indicates the possible root causes of the error or provides hints and tips on where to find additional information about the error. This text is localized based on the locale (from the com_infoengine_locale property) of the data in the ESIResponse (For more information see Internationalization Considerations or the Implementing Windchill ESI for more details). Including this information in the message is enabled via a global variable ESIMessaging/RootCause. For more information, see the Return Messaging Flags section. For example, "For more information about this error, see the SAP Internal Application Log (transaction SLG1)." |

ERP Primary Message | If applicable, the primary API return message from the ERP system. For SAP distribution targets, when using SAP BAPIs, this may include the following SAP message parameters, delimited by colons, with leading and trailing spaces removed: • Type (A, E, S, I, W, X) • ID • Number • Text For SAP CCAP and CSAP remotely-enabled API function modules, this field may be the object name or internal SAP object number. This text is not localized (See the Internationalization Considerations section in the Installing and Configuring Windchill ESI in an SAP Environment for more details). Including this information in the message is enabled via a global variable ESIMessaging/ERPPrimary.For more information, see the Return Messaging Flags section. For example: S:MM:356: The material GS_700_IB4D has been created or extended |

ERP Secondary Message | If applicable, the secondary API return message from the ERP system. For SAP distribution targets, when using SAP BAPIs, this may include the following SAP message parameters, delimited by colons, with leading and trailing spaces removed: • Type (A, E, S, I, W, X) • ID • Number • Text For SAP CCAP and CSAP remotely-enabled API function modules, this field will typically remain empty. Each secondary information entry is delimited by semicolons This text is not localized. For more information, see the Internationalization Considerations section in the Installing and Configuring Windchill ESI in an SAP Environment. Including this information in the message is enabled via a global variable ESIMessaging/ERPPrimary. For example: H:MK:102:Trying to create: GS_700_IB4D 1200; S:M3:800:Material GS_700_IB4D created; H:MK:103:Trying to change: GS_700_IB4D 1200; S:M3:810:No changes made |

EAI Additional Information | Any pertinent information from EAI components (non-ERP). This text is not localized. See the Return Messaging Flags section for more details. For example, in the case of an error, this field might contain a stack trace. |

Extra Information | An additional field for customization. |

Flag | Description |

ESIMessaging/ERPPrimary | Enables returning ERP primary information to Windchill PDMLink. For more information, see the Components of ESIPostResult Message section. |

ESIMessaging/ERPSecondary | Enables returning ERP secondary information to Windchill PDMLink. For more information, see the Components of ESIPostResult Message section. |

ESIMessaging/RootCause | Enables returning root cause information to Windchill PDMLink. For more information, see the Components of ESIPostResult Message section. |

ESIMessaging/EAISecondary | Enables returning functional decision/warning information to Windchill PDMLink. For more information, see the Components of ESIPostResult Message section. |

Code/ Action | Severity | Send Sub- transactions Messages to Windchill | Send Overall Transaction Messages to Windchill | Continue Processing1 | Stop Processing |

0 | None2 | X | |||

1 | 0 | X | |||

2 | 0 | X | X | ||

3 | 0 | X | X | X | |

4 | 1 | X | X | ||

5 | 1 | X |

Error Code Number | Windchill PDMLink Notification | Final Action |

0 | NoWindchill PDMLink notification | Processing stops |

1 | NoWindchill PDMLink notification | Processing stops |

2 | Windchill ESI sends a PostResult message toWindchill PDMLink for the overall release transaction. | Processing stops |

3 | Windchill ESI sends a PostResult message toWindchill PDMLink for the subtransaction as well as for the overall release transaction. | Processing stops |

4 | Windchill ESI sends a PostResult message toWindchill PDMLink for the subtransaction. | Continues processing and returns to where the error handler was called |

5 | NoWindchill PDMLink notification | Continues processing and returns to where the error handler was called |