Manufacturing Process Management

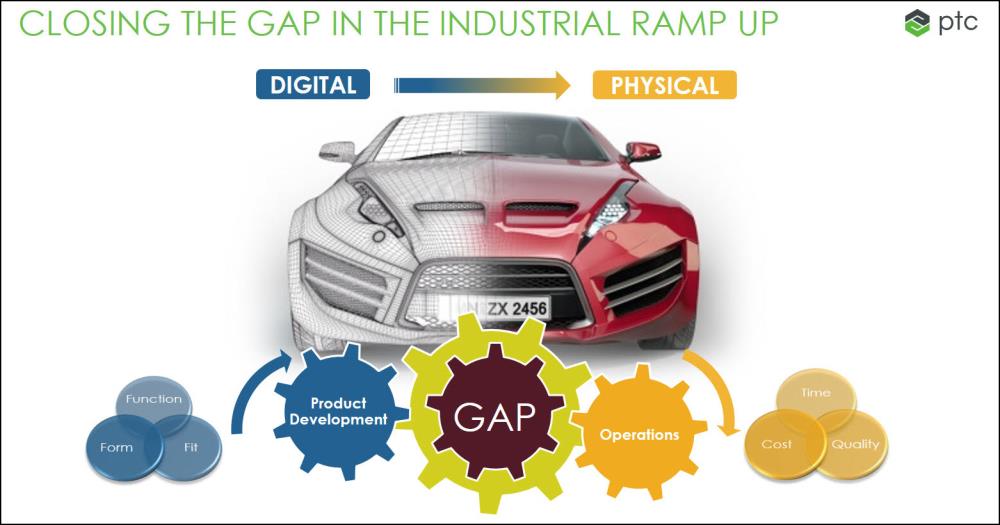

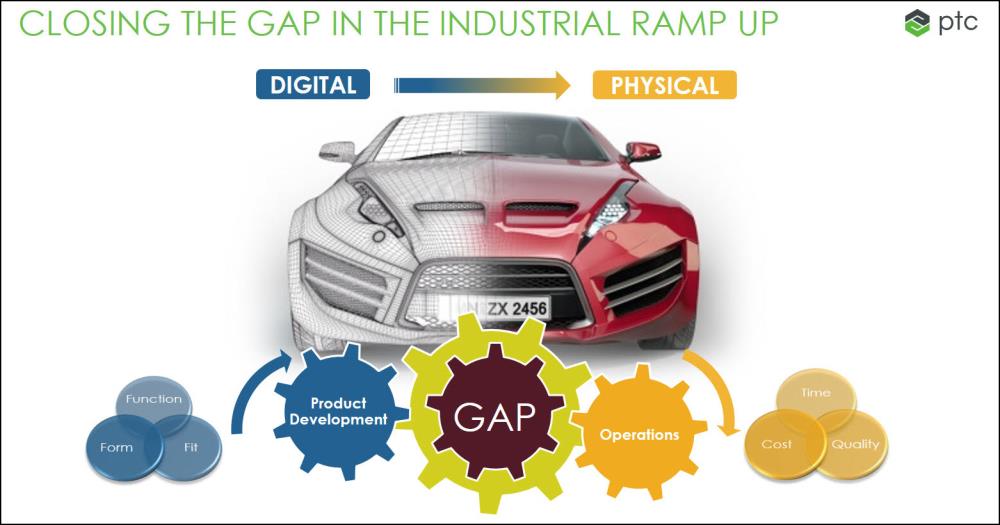

Manufacturing Process Management (MPM) is the process of defining and managing the manufacturing processes used to make parts, assemble final products, and perform inspections. In any product life cycle management (PLM) system, the MPM process is the necessary bridge from product design to production execution. As the digital manufacturing part of the PLM process, it is the bridge from product design to production planning, and on to resource and inventory scheduling.

Whereas the focus of many engineering centric processes is on defining "what" the product is, MPM focuses on defining "how" to produce it. More specifically, the MPM process is the business process through which the manufacturing engineer defines the detailed sequences of operations required in production to produce parts from raw material, to assemble the final product and to perform other production related tasks like inspection. During MPM, the manufacturing engineer accesses the digital product definition, considers the available manufacturing capabilities, and designs the mBOMs, process plans, and work instructions required to produce the product. MPM also involves giving early feedback to engineering based on preliminary versions of the manufacturing deliverables, validating and optimizing these deliverables, and releasing information to production systems (ERP/MES).

PTC's Manufacturing Process Management Solution, Windchill MPMLink, enables the manufacturing engineer to associatively transform the engineering BOM to the manufacturing BOM, to manage libraries of manufacturing resources and standardized manufacturing capabilities, to define digital definitions of process plans with associative links to the mBOMs and manufacturing resources, and to dynamically generate work instructions for the shop floor.