Product Development Foundations

Product development ranges widely in scale from simple to complex. There are a variety of strategies to develop products varying from single parts and static Bill-of-Materials (BOM) to configurable structures that represent a whole family of products.

Parts form the foundation of the BOM structure and can identify a single item, such as a bolt or a resistor, or an entire product such as a computer or aircraft, comprising thousands to millions of parts. BOMs contain all critical product details such as part quantity, unit of measure, and other key product characteristics.

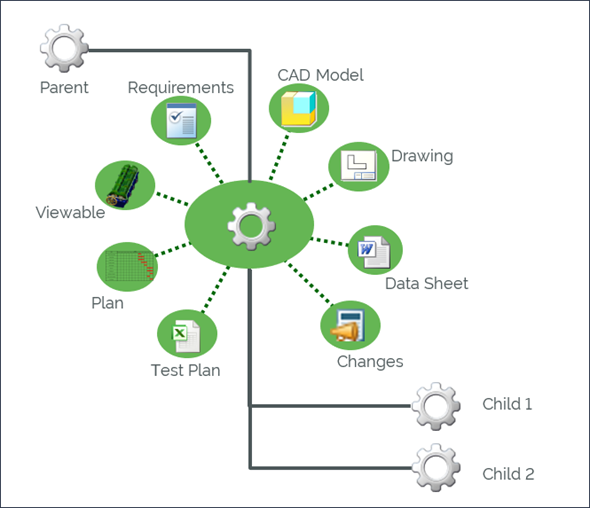

With Windchill, parts enable delivery of a holistic digital product definition with a multidisciplinary BOM allowing the enterprise access to a broad range of product information including Parts and BOM, related CAD data, Visualization, Documents, Classification data and Supplier Parts. All this information can be leveraged in downstream process requirements such as Manufacturing or Services BOMs and documentation. This rich information also serves a broader set of enterprise requirements across supply chain, manufacturing, service, product management, and more.

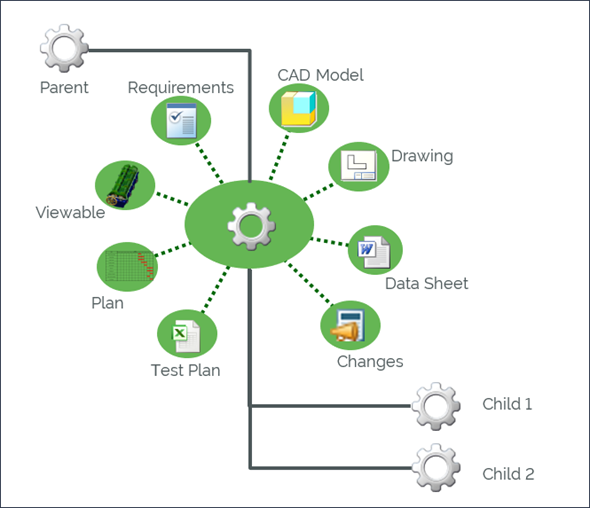

There are several strategies for developing BOMs using parts. For any given company, there might be one or more of these strategies that make sense both within and across a product line.

• Single BOM: represents the structure of a product as it evolves over time.

• Configurable BOM: represents the platform supporting a broad range of market demands.

For any given company, there can be a mix of strategies used in planning and creating product definitions that can differ by product offerings, business units and more. Windchill is flexible in enabling a company to leverage different BOM strategies as required.

Single BOM

Managing BOMs allows the creation of a rich digital product definition containing not just the part structure, but access to a broad set of information required to understand that product. It provides the enterprise access to full set of data that can be used in planning, purchasing, service and customer requirements. To create or evolve a BOM, any of the following methods may be used in combination.

• Manually: A user manually builds a BOM with existing and new parts. While creating the BOM, users define required information such as quantity, Find Number, or other attributes about the parts and their usage. This provides the framework for a complete BOM – or a complete digital product definition – that includes mechanical, electrical, software-related information, and more. Organizations gather this additional information using one of the methods described below. With this method, a user may also create related CAD data allowing one to build a CAD assembly via a “Top-Down” strategy.

• From CAD: By leveraging existing CAD models and assemblies – such as MCAD and ECAD – a user may generate a BOM from scratch. This is generally known as the “Bottom-up” method that allows the rapid creation of a BOM. Options exist to determine which CAD models should drive the BOM structure and which CAD models are just information required for CAD modelling. This lowers the effort while accelerating the BOM creation. It also allows for a more complete BOM definition by incorporating a broader range of information into the BOM.

• Import from Spreadsheets: One of the quickest ways to create a BOM is by calling upon existing data from legacy systems or provided by supply partners in the form of a spreadsheet. Spreadsheets are a common tool for modifying this data before importing it into a part-centric BOM management solution to create the BOM. Certain solutions will enforce your enterprise policies as this data is fed into the system.

• Reuse existing parts and BOMs: Rather than rebuilding BOMs, existing BOMs can be reused to quickly create new products with techniques such as Save As. Use of these techniques allows you to reuse most of an existing BOM while only creating new parts where required including related CAD and documents.

Configurable BOM

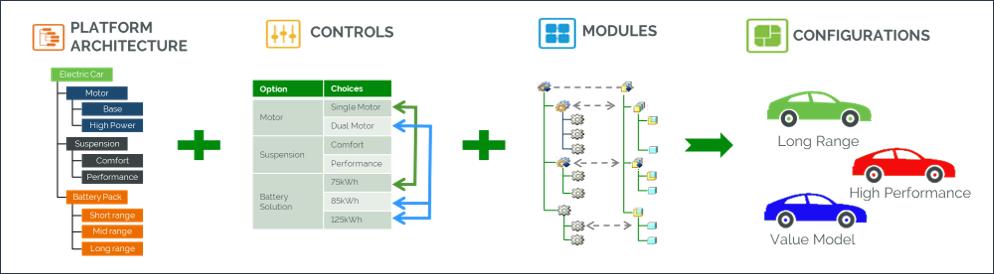

The configurable BOM solutions in Windchill help companies plan, innovate, and consolidate their product platforms to support a broad range of market demands for their product families while optimizing number of variants required for each module of the product. This includes capabilities to define and manage product families, options, logic and enterprise configurations, interfaces, configurable deliverables such as CAD that can be managed with change management governance. These capabilities can be used for virtual validation such as Interference Detection as well as leveraging in downstream requirements such as manufacturing process planning and service documentation. Additionally, the logic and configurable platform can be shared with external tools such as CPQ or ERP to enable enterprise reuse of logic to ensure alignment across the team.

• Manage Complex Platform Configurations

◦ Manage product definition across the full lifecycle

◦ Support change management of the entire bill of information

◦ Maintain complete configurations of product families

• Plan and Define the Platform

◦ Allow for the architecting and development of modular platforms

◦ Analyze market requirements and plan for platform offerings

◦ Allow for the definition of a modular product architecture

◦ Plan product families using platform logic

◦ Support the analysis and validation of variant configurations

• Share the Platform

◦ Share product configurations and logic throughout the extended enterprise

◦ Leverage platform definition and configuration logic in manufacturing planning

◦ Send configuration-specific manufacturing BOM to production

◦ Provide Bill of Process information based on product variants

◦ Synchronize changes from design through to plant-specific production and ERP systems

Managing Product Definition Throughout the Lifecycle

All the BOM strategies can be managed using the powerful Configuration and Change Management capabilities in Windchill. Windchill provides configuration management capabilities to define how the product matures as well as what is available to engineering, manufacturing, supply chain, and other organization roles enabling any participant to get the accurate product and other relevant information. Managing configuration information as part of the normal development process can be accomplished in many ways depending upon the requirements of the business process. Capturing this information enables delivering it back to users dynamically based on their specific configuration requirements such as Effectivity, Baselines, Lifecycle States, As-Matured, and more.

Windchill enables the management and tracking of changes to part and BOM information in a holistic fashion with the entire digital product definition. The system allows definition of change processes that scale with the requirements of an organization and change over time from simple to complex and fast and light to highly rigorous. These Change processes can incorporate Issue Management, Deviation/Waiver and ties to the Quality process as well. The change management process provides a broad range of abilities to manage the lifecycle:

• Highly scalable change processes enabling user participation and enterprise visibility

• Streamlining interaction with Change and Work-in-Process

• Improving decision quality with planning and validation tools during the Change process