Alternate BOMs

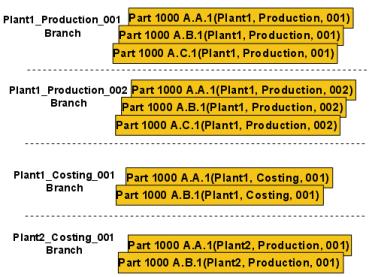

Alternative BOMs provide a different way to produce a product. They include a list of all the parts and their quantities required to build the product or assembly using the same manufacturing part number as an existing BOM. For example, you can use an alternate BOM to support the production of the same object in different manufacturing plants using a different material (gold vs. silver), or to take into account different BOM types (Production, Testing, Costing), or to support the definition of alternate production methods (for example, if lot size is significantly different).

Windchill MPMLink has extended standard Windchill view mechanisms with the ability to create Alternate BOMs. Adding these capabilities to Windchill MPMLink allows the manufacturing engineer to:

• Create different mBOMs for the same manufacturing part.

• Within the same plant, support different mBOM compositions for different BOM types. Create different types of BOMs (for example, production BOMs and service BOMs) using the same manufacturing parts.

• Within the same plant and for the same BOM Type, support definition of alternates due to various manufacturing constraints (ex: Lot Size).

When creating a part, the following attributes can be modified:

• BOM Type

• Alternate BOM

Along with the standard Windchill view mechanisms these attributes can be used to uniquely identify a different branch for a part.

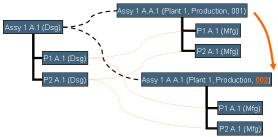

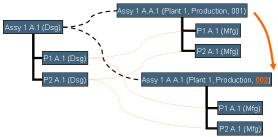

| Assemblies that have alternate BOMs have an indicator displayed in the navigation pane of the MAPSB, and all alternate BOMs are listed in the Alternate BOM tab. |