Automatically Allocating Parts to an Operation in PPB Using Attribute Mapping and Range-Based Approach

In the Process Plan Browser (PPB), you can allocate multiple parts to an operation in a single click. You can use the automatic part allocation feature in MPMLink by using the following two methods:

1. Matching two attributes — You can specify the same values for the attributes created on operations and part usages. If the system finds the same attribute values, it allocates the part usage under the operation.

2. Creating an attribute to define the range — You can specify a range for operations under a process plan. After specifying the range, you can use the Auto Allocate Assembly or Auto Part Allocation actions to allocate the parts with values within the specified range to operations under the process plan. Before specifying a range, you must specify a delimiter value in the Delimiter to Define the Range preference. The default delimiter value for this preference is >. You can also specify the delimiter of your choice. For example, -, @, >>, <, and so on.

You can create an attribute on the Manufacturing Operation Usage Link to define the range. To assign individual values to parts, you can create an attribute on Part Usage and use it to assign individual values to parts.

|

|

• The data type of the attributes created on the Manufacturing Operation Usage Link and Part Usage can be String, Integer Number, or Real Number. However, the data type cannot be Boolean.

• The names of the attributes created on the Manufacturing Operation Usage Link and Part Usage can be the same or different, based on your business use case.

|

For both methods, you can then map the attributes created on operations and part usages using the Attribute Mapping Name for Automatic Part Allocation preference. This preference defines the attribute mapping name for the automatic part allocation. You can specify the value in the following format: Part_Usage_Attribute:Operation_Usage_Attribute. For example, Part_Usage:Operation_Usage. The values indicate the mapping between the part usages and the operation usages. You must specify the part usage attribute before the operation usage attribute. The default value is VMS:VMS.

For more information, see the following use cases:

Use Case 1: Auto Allocating Parts using One-to-One Mapping

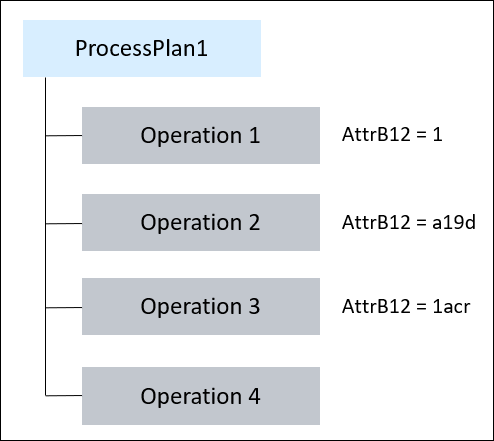

1. Consider that the following structure is present in Process Plan Browser.

Use the Type and Attribute Management utility to create and add the attribute AttrB12 on Manufacturing Operation Usage Link.

You can view the attribute AttrB12 in the Uses tab of the Process Plan Browser.

ProcessPlan1 has four operations under it. The value of the range attribute AttrB12 is 1, a19d, and 1acr for Operation 1, Operation 2, and Operation 3, respectively.

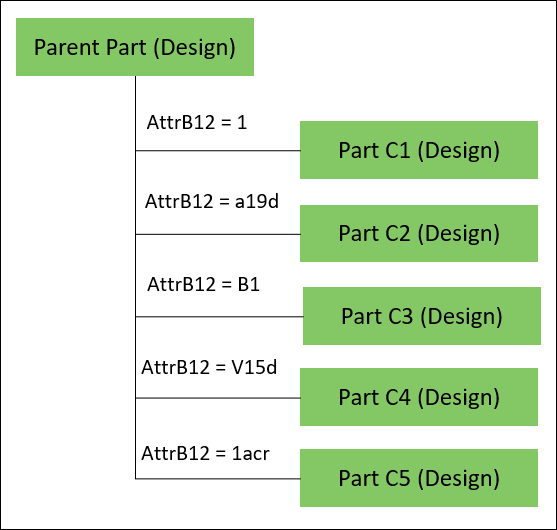

2. The following structure is present in the BOM Transformer:

Use the Type and Attribute Management utility to create and add the attribute AttrB12 on Part Usage. You can view the AttrB12 attribute in the Uses tab of the BOM Transformer.

The value of the attribute AttrB12 is 1, a19d, B1, V15dand 1acr for Part C1 (Design), Part C2 (Design), Part C3 (Design), Part C4 (Design), and Part C5 (Design).

The data type of the attributes created on the Manufacturing Operation Usage Link and Part Usage can be String, Integer Number, or Real Number. However, the data type cannot be Boolean. |

3. Set the value of the Attribute Mapping Name for Automatic Part Allocation preference to AttrB12:AttrB12.

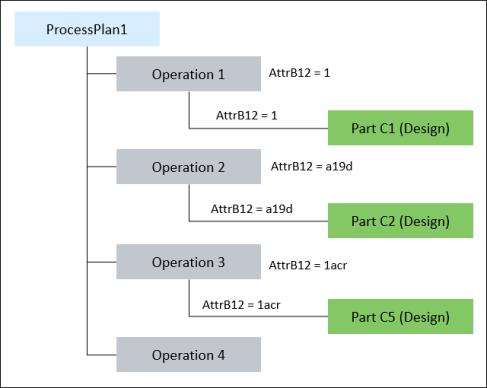

4. In PPB, initiate the Auto Allocate Assembly action. The updated structure appears as follows:

◦ The system allocates Part C1 (Design) under Operation 1 as the value of the attribute AttrB12 for Part C1 (Design) matches with the value of the attribute AttrB12 for Operation 1.

◦ The system allocates Part C2 (Design) under Operation 2 as the value of the attribute AttrB12 for Part C2 (Design) matches with the value of the attribute AttrB12 for Operation 2.

◦ The system allocates Part C5 (Design) under Operation 3 as the value of the attribute AttrB12 for Part C5 (Design) matches with the value of the attribute AttrB12 for Operation 2.

◦ Part C3 and Part C4 are not allocated as they do not satisfy the specified criteria.

Use Case 2: Auto Allocating Parts Using Range Attribute

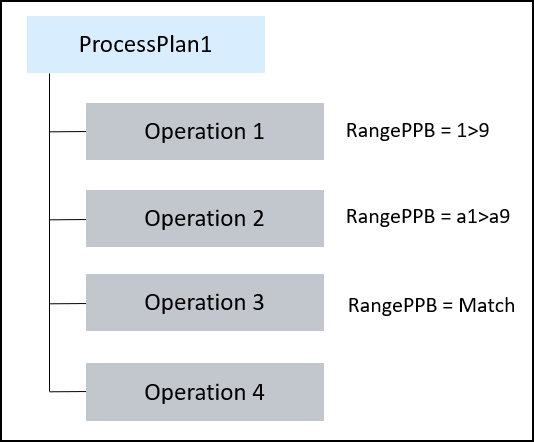

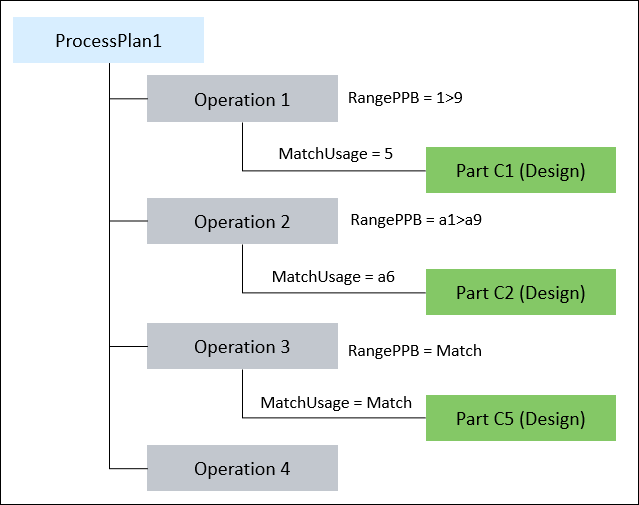

1. Consider that the following structure is present in the Process Plan Browser (PPB):

Use the Type and Attribute Management utility to create and add the range attribute RangePPB on Manufacturing Operation Usage Link. You can view the attribute RangePPB in the Uses tab of the Process Plan Browser.

ProcessPlan1 has four operations under it. The value of the range attribute RangePPB is 1>9, a1>a9, and Match for Operation 1, Operation 2, and Operation 3, respectively.

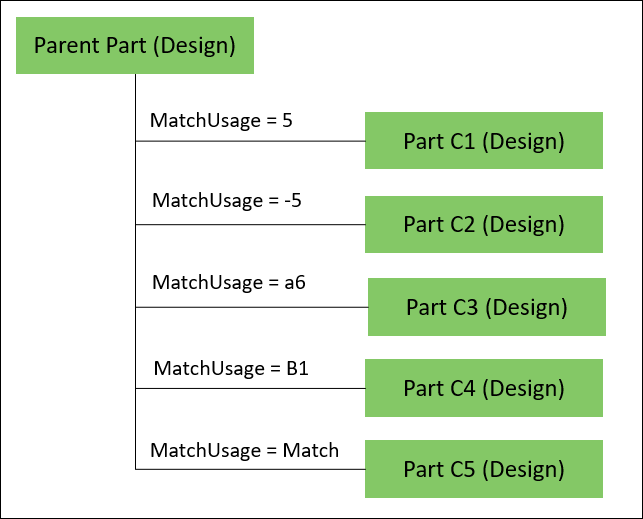

2. The following structure is present in the BOM Transformer:

Use the Type and Attribute Management utility to create and add the range attribute MatchUsage on Part Usage. You can view the MatchUsage attribute in the Uses tab of the BOM Transformer.

The value of the range attribute MatchUsage is 5, -5, a6, B1, and Match for Part C1 (Design), Part C2 (Design), Part C3 (Design), Part C4 (Design), and Part C5 (Design).

The data type of the attributes created on the Manufacturing Operation Usage Link and Part Usage can be String, Integer Number, or Real Number. However, the data type cannot be Boolean. |

3. Set the value of the Attribute Mapping Name for Automatic Part Allocation preference to MatchUsage:RangePPB. The values indicate the mapping between the part usages and the operation usages. You must specify the part usage attribute before the operation usage attribute.

4. In PPB, initiate the Auto Allocate Assembly action. The updated structure appears as follows:

◦ The system allocates Part C1 (Design) under Operation 1 as the value of the range attribute MatchUsage for Part C1 (Design) is 5 and the value of the range attribute RangePPB for Operation 1 is 1>9.

◦ The system allocates Part Cw (Design) under Operation 2 as the value of the range attribute MatchUsage for Part C2 (Design) is a6 and the value of the range attribute RangePPB for Operation 2 is a1>a9.

◦ The system allocates Part C5 (Design) under Operation 3 as the value of the range attribute MatchUsage for Part C5 (Design) is Match and the value of the range attribute RangePPB for Operation 3 is Match.

◦ Part C3 and Part C4 are not allocated as they do not satisfy the specified criteria.

Key Points

• If the specified range values for two different operations are the same or overlapping, the system does not allocate any parts under the operations even if they satisfy the specified range criteria.

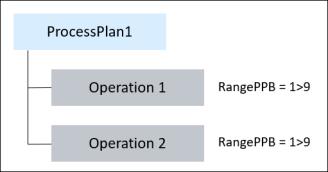

Example 1

The value of the attribute RangePPB for Operation 1 and Operation 2 is 1>9.

When you initiate the Auto Allocate Assembly action, the system does not allocate any part under any of the two operations.

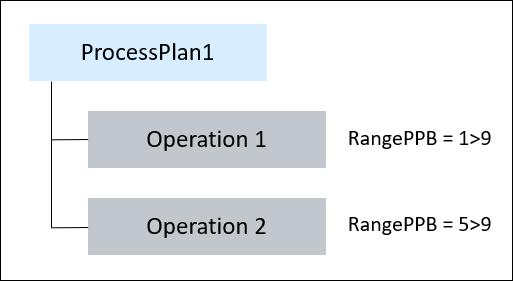

Example 2

The value of the attribute RangePPB for Operation 1 is 1>9 and for Operation 2 is 5>9.

When you initiate the Auto Allocate Assembly action, the system does not allocate parts under any of the two operations for which the RangePPB attribute is 5, 6, 7, 8 or 9. The parts with the RangePPB attribute values 1, 2, 3, or 4 can be allocated.

• The system processes the range that you specified in lexicographic order.

• If you want to define the open range for an operation usage attribute value, then you can specify a value such as A3>.

• An operation usage can have multiple ranges such as A1>A8, B1>B3, C4>C8. You must specify these values separated by a semicolon. For example, A1>A8;B1>B3;C4>C8. In this case, parts with parts usage values as A2, B2, and C5 are allocated to an operation.

• Out of the box, you cannot use the following reserved characters as a delimiter: &, &&, and &&&.

• If there are multiple parts with the same usage attribute value, all the parts are allocated to the matching operation.

• The Auto Part Allocation action is enabled only when the value of the Auto Part Allocation preference is set to Yes.