Automatically Allocate Parts to An Existing Process Plan Based On Derived Logic

In the Process Plan Browser, you can use the  Auto Allocate Assembly action to automatically allocate new parts to operations based on the previous allocation of the parts from other related assemblies. The

Auto Allocate Assembly action to automatically allocate new parts to operations based on the previous allocation of the parts from other related assemblies. The  Auto Allocate Assembly action is available on the Tree Picker toolbar.

Auto Allocate Assembly action is available on the Tree Picker toolbar.

Auto Allocate Assembly action to automatically allocate new parts to operations based on the previous allocation of the parts from other related assemblies. The

Auto Allocate Assembly action to automatically allocate new parts to operations based on the previous allocation of the parts from other related assemblies. The  Auto Allocate Assembly action is available on the Tree Picker toolbar.

Auto Allocate Assembly action is available on the Tree Picker toolbar.• Once you click the  Auto Allocate Assembly action, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. Auto Allocate Assembly action, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related.• The auto allocation using the  Auto Allocate Assembly action happens only if the value of the Allow Allocation from Multiple Assemblies for a Process Plan is set to Yes. The default value of this preference is No. Auto Allocate Assembly action happens only if the value of the Allow Allocation from Multiple Assemblies for a Process Plan is set to Yes. The default value of this preference is No. |

Business Use Case

A process plan can have multiple operations present under it. Multiple assemblies can be already related to a process plan. Some of the components from those assemblies can already be allocated to the operations of the same process plan. Consider a scenario where parts in a truck are already allocated under the operations in the process plan. The truck can have multiple variants. Majority of the parts are common in all the variants. You can auto allocate parts that are common among the variants by opening each variant in the Tree Picker and clicking Auto Allocate Assembly. For example, Truck M has four variants; V1, V2, V3, and V4. 80 % of the parts are common between M, V1, V2, V3, and V4. The common parts from Truck M are already allocated to operations in the process plan. You can open the individual assemblies of V1, V2, V3, and V4 in the tree picker and click Auto Allocate Assembly action to complete the automatic allocation of the common parts. Based on the logic, the system finds the operations under which the respective parts of variants were already allocated for Truck M. The system then allocates the same parts for V1, V2, V3, and V4 to the same operations.

The following use cases provides more information about the logic that the system applies while auto allocating the parts under operations:

Use Case 1 : Process Plan Created in Usage Mode

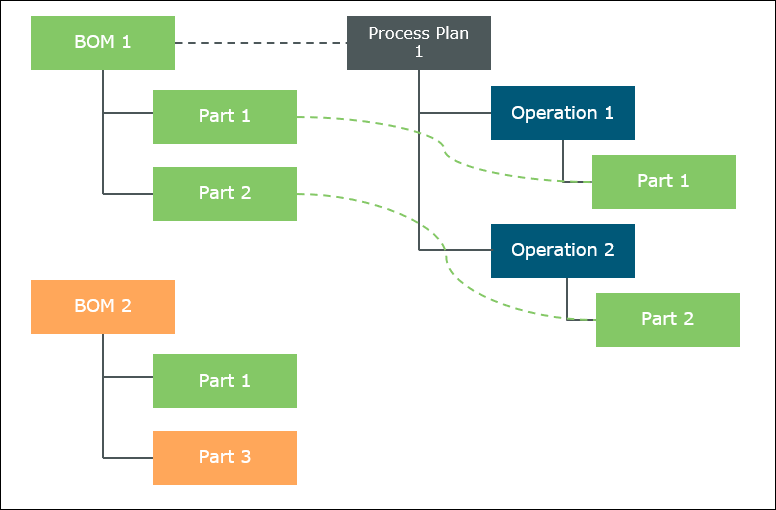

Consider that the following structure is present in the Structure tab of Process Plan Browser :

• BOM 1 is already related to Process Plan 1.

• Part 1 is already allocated under Operation 1.

• Part 2 is already allocated under Operation 2.

1. Open BOM 2 in the Tree Picker of the Process Plan Browser.

Part 1 is the common part between BOM 1 and BOM 2.

2. Click  Auto Allocate Assembly in the Tree Picker toolbar.

Auto Allocate Assembly in the Tree Picker toolbar.

Auto Allocate Assembly in the Tree Picker toolbar.

Auto Allocate Assembly in the Tree Picker toolbar.

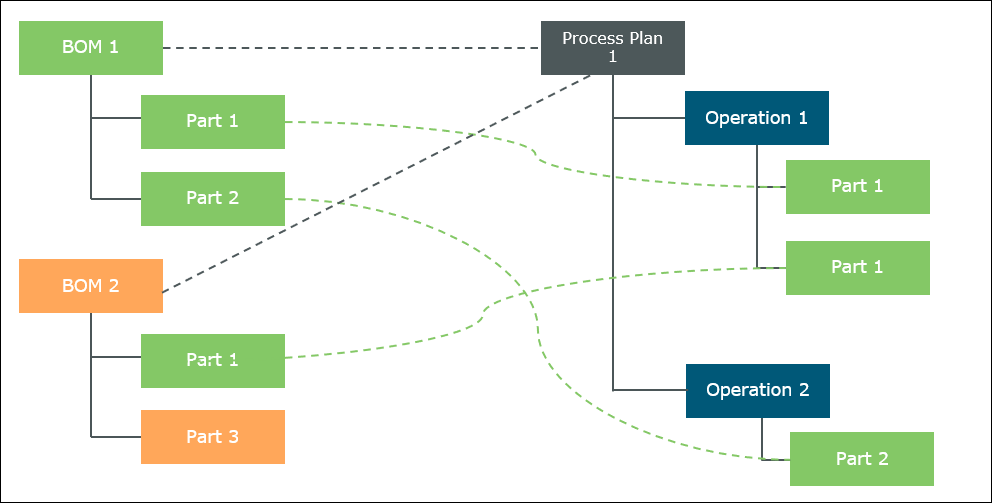

Once you click  Auto Allocate Assembly, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. In this case, the system relates BOM 2 to Process Plan 1.

Auto Allocate Assembly, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. In this case, the system relates BOM 2 to Process Plan 1.

Auto Allocate Assembly, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. In this case, the system relates BOM 2 to Process Plan 1.

Auto Allocate Assembly, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. In this case, the system relates BOM 2 to Process Plan 1.The system then verifies if the common part between BOM 1 and BOM 2 is already allocated to any operation in the process plan. If the system finds such operation, it allocates the part in the newly related assembly under the same operation. In this case, the system finds that Part 1 in BOM 1 is already allocated under Operation 1. Because of this, the system allocates Part 1 in BOM 2 under the same operation, that is, Operation 1.

The system did not find Part 3 allocated for any previous assembly under any operation. Hence, it did not allocate Part 3 under any operation. The parts that are not allocated by the  Auto Allocate Assembly action must be allocated manually. In this case, you must allocate Part 3 in BOM 2 manually.

Auto Allocate Assembly action must be allocated manually. In this case, you must allocate Part 3 in BOM 2 manually.

Auto Allocate Assembly action must be allocated manually. In this case, you must allocate Part 3 in BOM 2 manually.

Auto Allocate Assembly action must be allocated manually. In this case, you must allocate Part 3 in BOM 2 manually.• Consider that Part 1 is used multiple times in BOM 1 and BOM 2. In this case, the system compares the position of the usages of Part 1 in BOM 1 and BOM 2 to identify the unique part. If the system finds a usage with matching positions, it allocates this particular usage to an operation. In this case, position means the placement of the individual part instance in 3D view. • The already allocated parts from new assemblies are not allocated by the system. |

Use Case 2: Process Plan Created in Occurrence Mode

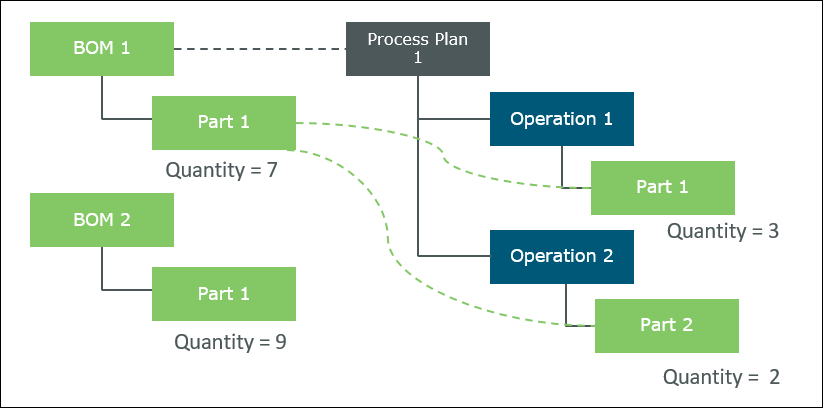

Consider that the following structure is present in the Structure tab of Process Plan Browser :

• BOM 1 is already related to Process Plan 1.

• Quantity 7 of Part 1 is present under BOM 1.

• Quantity 3 of Part 1 is already allocated under Operation 1.

• Quantity 2 of Part 1 is already allocated under Operation 2.

1. Open BOM 2 in the Tree Picker of Process Plan Browser.

Part 1 is the common part between BOM 1 and BOM 2.

2. Click  Auto Allocate Assembly in the Tree Picker toolbar.

Auto Allocate Assembly in the Tree Picker toolbar.

Auto Allocate Assembly in the Tree Picker toolbar.

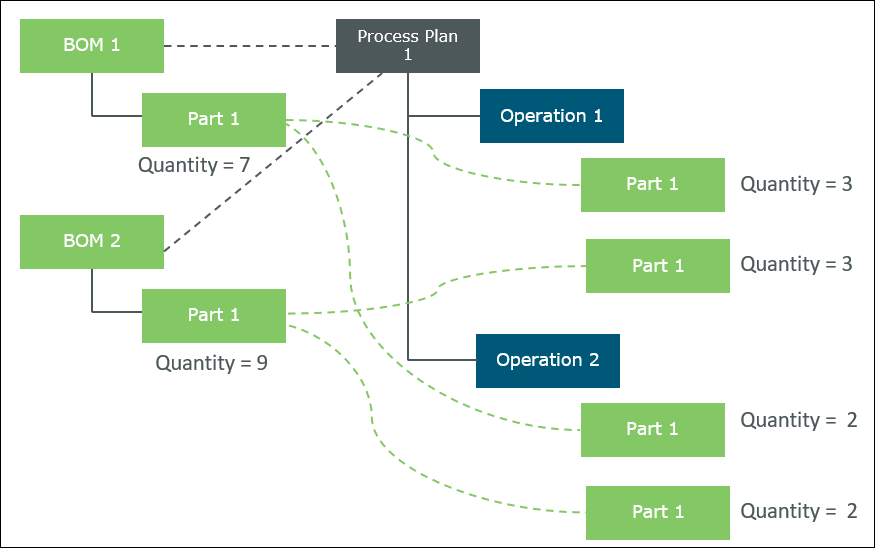

Auto Allocate Assembly in the Tree Picker toolbar.Once you click  Auto Allocate Assembly, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. In this case, the system relates BOM 2 to Process Plan 1.

Auto Allocate Assembly, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. In this case, the system relates BOM 2 to Process Plan 1.

Auto Allocate Assembly, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. In this case, the system relates BOM 2 to Process Plan 1.

Auto Allocate Assembly, the system relates the assembly opened in Tree Picker to the process plan, if the assembly is not already related. In this case, the system relates BOM 2 to Process Plan 1.

The system then verifies if the common part between BOM 1 and BOM 2 is already allocated to any operation in the process plan. If the system finds such operation, it allocates the same quantity of the part under the same operation based on matching position value. Because of this, the system allocates quantity 3 of Part 1 in BOM 2 under Operation 1 and quantity 2 of Part 1 in BOM 2 to Operation 2.

The remaining quantity of Part 1 in BOM 2 that is not allocated must be allocated manually.

• For process plans created in occurrence mode, the system compares the positions of the individual occurrences for allocation. • Consider that Part 1 in BOM 2 has quantity 4. This is less than the total allocated quantity under Operation 1 and Operation 2. In such case, for allocation the system compares the positions of the individual occurrences, that is, placement of the individual part instance in a 3D view |