Overview of PTC FlexPLM

Product development is a complex process. Outsourcing, globalization, the Internet, and a strong customer focus all add to our existing intense time and cost pressures. As a result, the product development process must now engage a variety of cross-functional participants in a value chain that includes developers, suppliers, partners, and customers in multiple geographic locations.

The most efficient way to control this process is by using a product lifecycle management (PLM) system to manage products from concept through the end of life. PLM has gained wide acceptance as the primary means to improve product development processes across the product development chain.

PLM is unique from other enterprise systems you might have used or encountered, because it is about products, not transactions. It should be viewed simply as an extension of your company’s existing enterprise transaction infrastructure.

PLM gives people at all levels and functions in the organization the ability to:

• Create digital representations of products

• Collaborate cross-functionally in an organization and throughout the product chain

• Control and manage product information and product development processes throughout the product’s lifecycle

PLM in the Retail, Footwear, and Apparel Industry

The retail, footwear, and apparel (RFA) product development process is fundamentally different than that of discrete manufacturing, which has driven the development of traditional PLM. The RFA industry’s volatile supply chains require a different form of PLM flexibility. Retail, footwear, and apparel product designs are intensely driven by emotional concepts and decisions, fashion trends, material innovation, and new fabric technology—development considerations not taken into account in manufacturing-driven PLM methodologies. Traditional PLM offerings have not adequately addressed the collaborative and creative nature of the retail, footwear, and apparel industry.

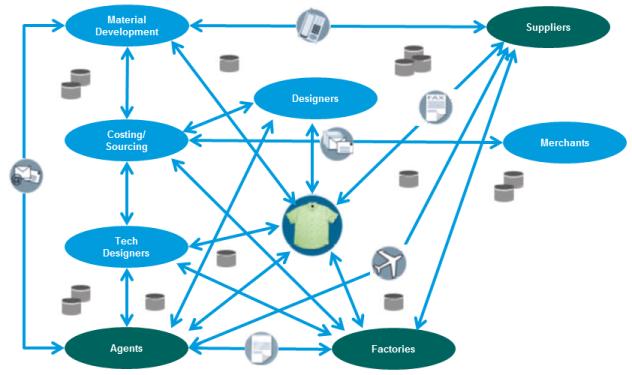

The illustration below shows the complexity of the RFA value chain. In a non-PLM development process, there are numerous points of communication with limited process visibility. The process is not centralized, resulting in multiple versions of a product, needless duplication of effort, and an overall lack of control of the process.

Benefits of PTC FlexPLM

PTC FlexPLM, in conjunction with Windchill technology, was developed specifically to address the needs of the RFA industry. PTC FlexPLM addresses the four most important retail, footwear, and apparel initiatives:

• Reduce Time to Market—With PTC FlexPLM, everyone in the product life cycle process is a player. Having everyone involved improves collaboration with vendors, reduces the number of specification changes, and improves your design productivity by including all relevant participants in each stage of the design process.

• Reduce Total Product Cost—Two significant characteristics of the RFA industry are its short product development timeframes and the large aggregation of materials needed to produce a single garment. Couple this with the demand from manufacturers and retailers for earlier and larger commitments of inventory, and cost considerations can be overwhelming. PTC FlexPLM allows an enterprise to reduce the number of samples and to improve design review efficiency. These cost savings can be measured in many areas, including color and fit management, line development, and consumption of raw materials.

• Improve Product Quality—Product quality can often be improved by increased attention to detail. PTC FlexPLM allows precise management of data access and accuracy, adherence to quality standards, and improved control over product specifications.

• Improve Information Exchange—The effective and uncluttered exchange of information is essential to the success and profit of any business. PTC FlexPLM offers the RFA enterprise improved collaboration, both internally and with customers. PTC FlexPLM consolidates the locations of product information to avoid duplication or fault categorization of product data. Additionally, improved collaboration with suppliers and vendors results in more rapid construction times and more accurate product results.

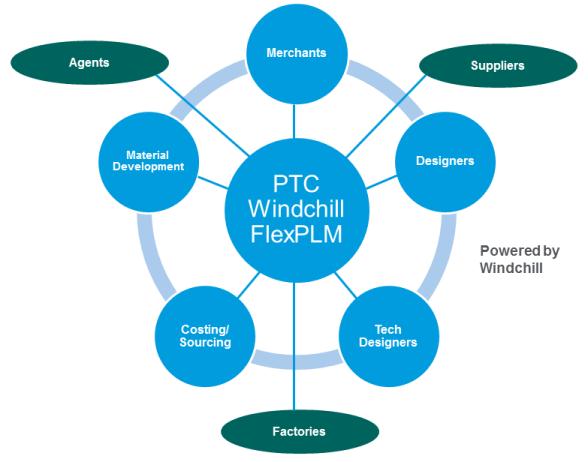

With these initiatives in mind, PTC FlexPLM brings process automation control to the dynamic RFA industry. Instead of the scattered and disjointed product development process shown in the previous illustration, PTC FlexPLM brings a structured, centralized, and controlled approach to the RFA enterprise.