Inventory

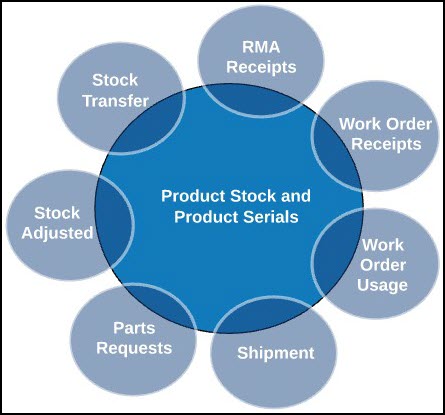

The following diagram depicts the high-level Inventory Process.

The basic Inventory module in ServiceMax enables tracking stock operations related to field service locations (customers’ locations and technicians’ trunk stock locations) as well as internal storage locations such as warehouses. It supports stock adjustment, stock transfer, parts requests, and receipts, and maintains the complete history of stock transactions of items across multiple locations. This module also provides interactive stock lookup tools.

ServiceMax inventory enables capturing, monitoring, and automatic updates of parts inventory. To track inventory in a warehouse, repair center, or field location, a stock location must be defined. With ServiceMax, you also have the option to track product inventory with serial numbers. Stock can also be tracked based on status such as Available, In Transit, and Consumed. The inventory is updated automatically based on user actions in various transactions such as RMA, Shipment, Work Order, and Stock Transfer.

Service Parts and Reverse Logistics module supports complex business processes related to inventory, which encompass the following:

• Bulk returns through dealers.

• Inventory movement through receiving and shipping centers, transferring hubs, and delivery and repair locations.

• Rule-based routing of IBs and parts between customers and repair centers.

• Management of repairs, advanced returns, replacements, and product substitutions.