Changing and Updating Outside Diameters

Use the sample files provided at

<Creo load point>\Common Files\help\sample_models\piping when working in this exercise. It is recommended that you create a copy of the

piping folder on your computer and

set up piping data before you start working with the tutorial.

Workflow

1. Create a pipe segment.

2. Change pipe diameter in the Pipe catalog.

3. Update pipe diameter in the model.

Create a Pipe Segment

1. On the

Home tab, click

New

New. The

New dialog box opens.

2. Under

Type, click

Assembly

Assembly.

3. Click OK to create a new assembly.

4. Click

Applications >

Piping

Piping. The

Piping tab opens.

5. On the Piping tab, select the Spec Driven check box.

6. Click

Create Pipe

Create Pipe. The

Create Pipeline dialog box opens.

7. In the Number box, type a.

8. Click OK. The Create Pipeline dialog box closes.

9. Click

Set Start

Set Start. The

Define Start dialog box opens.

10. Select ASM_DEF_CSYS in the graphics window.

11. Click OK. The Define Start dialog box closes.

12. Click

Extend

Extend. The

Extend dialog box opens.

13. Drag a dragger handle along the z-axis and click Apply. A pipe segment is created.

14. Click Cancel. The Extend dialog box closes.

Change Pipe Diameter in the Pipe Catalog

1. In the piping folder, double-click the piping_data folder, and open the master_catalog folder.

2. Double-click the pipe folder and open the pipe_steel.csv file.

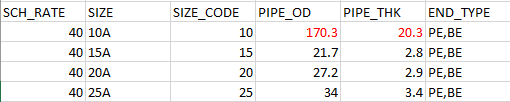

3. Update the following pipe diameter and pipe thickness values in the catalog:

SCH_RATE | SIZE | SIZE_CODE | PIPE_OD | PIPE_THK | END_TYPE | SCH_RATE |

40 | 10A | 10 | 170.3 | 20.3 | PE,BE | 40 |

In the following image, new values are in red:

4. Change the MATERIAL_DENSITY value to 0.78.

5. Save the Pipe master catalog file.

Update Pipe Diameter in the Model

1. Click Piping > Setup > Update Model. The Update Model dialog box opens.

2. Under

Model Information, click

to select all the options to update.

3. Click OK. The Confirm Cancel dialog box opens. Click Yes to confirm the update. The dialog boxes close and Spec-Driven Piping updates the active assembly information.

4. Click

Piping Info

Piping Info. The

Report Pipeline dialog box opens.

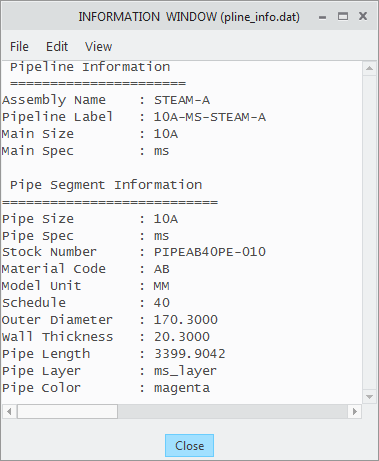

5. Select the segment 10A-MS-STEAM-A in the graphics window and click OK on the Select dialog box. The INFORMATION WINDOW opens.

|  The values of outer diameter and wall thickness are as entered in the Pipe MCAT file. |

6. Close the INFORMATION WINDOW and the Report Pipeline dialog box.

New. The New dialog box opens.

New. The New dialog box opens. New. The New dialog box opens.

New. The New dialog box opens. New. The New dialog box opens.

New. The New dialog box opens. Assembly.

Assembly. Piping. The Piping tab opens.

Piping. The Piping tab opens. Create Pipe. The Create Pipeline dialog box opens.

Create Pipe. The Create Pipeline dialog box opens. Set Start. The Define Start dialog box opens.

Set Start. The Define Start dialog box opens. Extend. The Extend dialog box opens.

Extend. The Extend dialog box opens.

to select all the options to update.

to select all the options to update. Piping Info. The Report Pipeline dialog box opens.

Piping Info. The Report Pipeline dialog box opens.