Temperature Results

Temperature Result

Temperature result shows the temperature distribution of the plastic at the end of filling. You can identify the following issues from the temperature result:

• Determine the region of high frictional heating—The flow resistance becomes very high near the gates and the low thickness region. The high flow resistance leads to frictional heating of the plastic melt. You should check for any temperature rise near the gate and low thickness region from the temperature result.

• Check if the temperature variation corresponds to change in the process conditions and design—You may modify the product design or process condition to get optimized results. Therefore, if you change the wall thickness, the temperature distribution changes because it is difficult for a thicker cavity to dissipate heat to the mold.

You can modify the design or the analysis settings to fix the molding issues.

Center Temperature Result

Center temperature result shows the melt temperature of the middle layer in the thickness direction at the end of filling. Center temperature is an indicator of the thermal energy supplied to the fresh hot melt. If the center temperature is too low, flow hesitation occurs, which can cause short shot problem.

Bulk Temperature Result

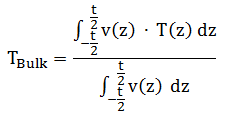

Bulk temperature is the velocity-weighted average melt temperature in the thickness direction at the end of filling. The equation for calculating the bulk temperature (TBulk) is as follows:

Assuming the direction of the model thickness is

where t is the thickness of the model, v is the velocity of the melt, and T is the temperature of the melt.

The result ignores the temperature contribution from the frozen layer. You can observe the effect of heat convection and viscous heating from this result. The bulk temperature shows the effect of heat convection on the temperature distribution of the hesitation and the viscous heating area.

The bulk temperature distribution reflects the trend of the flow path and therefore the actual path of pressure transmission.