Numerics

Flow Numerics

Numerics under the Flow module refers to parameters and models you use to control the numerical solver. Numerical options are set or selected for the Flow module in the Properties panel.

|

Numerics Options

|

Values

|

Description

|

|---|---|---|

|

Time Accuracy

|

Appears when the Common module entity in the Properties panel Time Definition is set to Transient. Select the Flow module and in the Properties panel > >

|

|

|

First Order

|

Default value for Time Accuracy. Determines temporal updates implicitly, based on the previous time step only.

|

|

|

Second Order

|

Determines temporal updates implicitly, based on the previous two time step. The relative influence of the two previous time steps depends on the Time Blending Factor and a Blending Options (Everywhere or Boundary Only) with reference to location.

|

|

|

Crank/Nicolson

|

Determines temporal updates based on the previous time step alone, using a combination of an explicit or implicit formulation. The relative influence of implicit versus explicit depends on the Time Blending Factor and a Blending Options (Everywhere or Boundary Only) with reference to location.

|

|

|

Automatic Relaxation

|

Yes or No

|

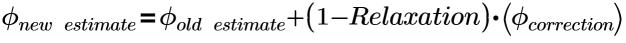

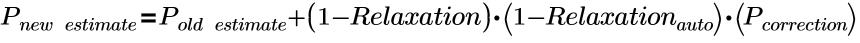

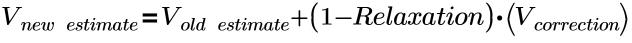

When you select the Automatic Relaxation value as Yes in the Properties panel, it adds additional linear relaxation for the pressure solution in Creo Flow Analysis as follows:  |

|

Relaxation

|

• Ranges from 0 to 1

• Typical values range from 0.0 to 0.8.

• Default value is 0

|

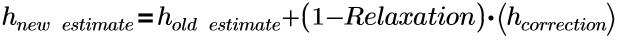

Controls the amount of correction applied during each iteration, using the following formula for Pressure and Velocity corrections:   • Relaxation of 0 has no value restrictions and allows complete application of correction. This is a recommended value, assuming there is no problem with the convergence. Higher values (> 0) are recommended to prevent diverging of a solution. • Value 1 is the most restrictive. It allows no correction of the solution from one iteration to the next. For Pressure, there is also an Automatic Relaxation. |

|

Diagonal Relaxation

|

• Ranges from 0 to infinity

• Typical values range from 0.001 to 1

• Default value is 0.3

|

Form of relaxation applied to the diagonal of the solution matrix. It has a similar effect to the influence of an old value at a previous time step. The flow module has separate values for the velocity and pressure corrections. During the solution process, the solver provides an estimate of the amount of correction needed to obtain an accurate solution. In general, relaxation refers to this suggested correction that is applied to the next iteration.

• Assuming there are no problems with the convergence, 0.3 is recommended for both Pressure and Velocity. If required, higher values (> 0.3) are recommended to prevent a solution from diverging.

• Value of 0 has no value restrictions and allows complete application of the correction.

• A large value is the most conservative, slowing down the corrections from one iteration to the next.

|

|

Numeric Scheme

|

Upwind

|

Sets the value at a cell interface based on the value from the cell that is upwind (upstream) of the interface of interest.

|

|

Central

|

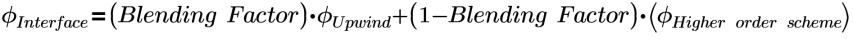

Sets the value at a cell interface using an average value from the cells on both sides of the interface of interest. You can use central differencing by setting Blending Factor and Bounded Scheme to control the convergence.

|

|

|

2nd Order Upwind

|

Sets the value at a cell interface based on a stencil of cells neighboring the interface of interest. You can use 2nd Order Upwind with a Blending Factor and a Bounded Scheme to help control the convergence.

|

|

|

• Blending Factor

|

0.1 to 0.5

|

Use the blending factor and the bounded scheme to stabilize convergence. Use Blending Factor with the higher order interpolation schemes such as Central and 2nd Order Upwind. This helps to stabilize the convergence by including the Upwind scheme using the equation listed below:  • Set Blending Factor to Central or 2nd Order Upwind schemes. • Higher values of the Blending Factor make the solution more stable. |

|

• Bounded Scheme

|

Use Bounded Scheme with the higher order interpolation schemes such as Central and 2nd Order Upwind. This helps to stabilize the convergence by limiting the range of the value of the interpolation to be not more or less than the maximum or minimum (respectively) of the cells neighboring the cell-face of interest.  In the Properties panel under the Flow module, you can set Bounded Scheme for velocity of Central or 2nd Order Upwind. |

|

|

Unlimited

|

No bounds are placed on the interpolation.

|

|

|

BC Only

|

Bounds are placed only on the faces next to the boundaries

|

|

|

Everywhere

|

Bounds are applied throughout the entire domain.

|

|

|

Linear Solver

|

AMG (Algebraic Multigrid Solver)

|

Default for Pressure

|

|

CGS (Conjugate Gradient Squared)

|

Default for Velocity

|

|

|

Sweeps

|

Default value is 50

|

The solution process in Creo Flow Analysis is iterative, including the Linear Solver. You can limit the total number of sweeps within a linear solver by setting the Sweeps to a maximum allowed value. If the solver reaches the maximum sweeps, it advances to the next variable.

• Number of sweeps is also controlled by the linear solver tolerance. In general, the solver should attain the desired tolerance before reaching the maximum number of sweeps.

• The number of sweeps used for a given iteration appear in the .out file as follows:

◦ INFO(Sim02:Flow:V:CGS): Residual: 4.19235 Sweeps = 1

◦ INFO(Sim02:Flow:P:AMG): Residual: 52.4886 Sweeps = 2

|

|

Linear Solver Tolerance

|

Default value is 0.1

|

The solution process in Creo Flow Analysis is iterative, including for the Linear Solver. You can control the total number of Sweeps within a Linear Solver by setting the Linear Solver Tolerance to the desired convergence tolerance. When the correction for the solver for a given variable falls below its Linear Solver Tolerance, the solver advances to the next variable.

• For the Flow module, Linear Solver Tolerance determines the Linear Solver convergence criterion for both the Pressure and Velocity solutions.

• A smaller value implies more precision.

• The cost of a smaller value is more sweeps which results in more computation time. In some cases, the added accuracy is not worth the additional expense. If the target Converge Criterion is very small, the solver may not be able to achieve it, and the solution advances to the full number of Sweeps allowed.

• The Residuals for Velocity and Pressure appear in the .out file as follows:

INFO(Sim02:Flow:V:CGS): Residual: 4.19235 Sweeps = 1 INFO(Sim02:Flow:P:AMG): Residual: 52.4886 Sweeps = 2

|

|

Pressure Velocity Coupling Method

|

Simple

|

Semi-Implicit Method for Pressure Linked Equations. Ref. Patankar, Numerical Heat Transfer and Fluid Flow, 1980, ISBN 0-07-048740-5

|

|

SIMPLEC

|

A general curvilinear coordinates pressure correction scheme (SIMPLEC). Semi-Implicit Method for Pressure-Linked Equations, Consistent. Ref: Doormaal, J., and G.D.Raithby, Enhancements of the SIMPLE method for predicting incompressible fluid flows, Num. Heat Transfer 7 (1984), 147–163

|

|

|

SimpleS

|

A Flow Analysis proprietary extension of the SIMPLEC algorithm.

|

Turbulence Numerics

Numerics under the Turbulence module refers to parameters and models used to control the numerical solvers forTurbulence variables. Numerical options are set or selected for the Turbulence module in the Properties panel. For the Turbulence module, you can set Numerics separately for the turbulent kinetic energy and the turbulent energy dissipation rate solutions.

|

Turbulence Module Numerics Options

|

Values

|

Description

|

|---|---|---|

|

Time Accuracy

|

Appears when the Common module entity in the Properties panel Time Definition is set to Transient. Select the Turbulence module and in the Properties panel > >

|

|

|

First Order

|

Default value for Time Accuracy. Determines temporal updates implicitly, based on the previous time step only.

|

|

|

Second Order

|

Determines temporal updates implicitly, based on the previous two time step. The relative influence of the two previous time steps depends on the Time Blending Factor and a Blending Options (Everywhere or. Boundary Only) with reference to location.

|

|

|

Crank/Nicolson

|

Determines temporal updates based on the previous time step alone, using a combination of an explicit or implicit formulation. The relative influence of implicit versus explicit depends on the Time Blending Factor and a Blending Options (Everywhere or. Boundary Only) with reference to location.

|

|

|

Relaxation

|

Controls the amount of correction applied during each iteration, using the following formula for Pressure and Velocity corrections:

|

|

|

Diagonal Relaxation

|

0.3, 0.3

|

Form of relaxation applied to the diagonal of the solution matrix. It has a similar effect to the influence of an old value at a previous time step.

|

|

Numeric Scheme

|

spatial interpolation

|

|

|

Upwind

|

||

|

Central

|

||

|

2nd Order Upwind

|

||

|

Linear Solver

|

CGS

|

Default for both the parameters

|

|

AMG

|

||

|

Sweeps

|

500, 500

|

Number of sweeps used for a given iteration appear in the *.out file as INFO(Sim01:Turbulence): Turbulence INFO(Sim01:Turbulence:tke:CGS): Residual: 0.633601 Sweeps = 1 INFO(Sim01:Turbulence:ted:CGS): Residual: 57.816 Sweeps = 1

|

|

Linear Solver Tolerance

|

Residuals for turbulent kinetic energy and the turbulent energy dissipation rate appear in the *.out file as follows:

• INFO(Sim01:Turbulence): Turbulence

• INFO(Sim01:Turbulence:tke:CGS): Residual: 0.633601 Sweeps = 1

• INFO(Sim01:Turbulence:ted:CGS): Residual: 57.816 Sweeps = 1

|

|

|

Turbulent Kinetic Energy

|

Default value is 0.1

|

|

|

Turbulent Energy Dissipation Rate

|

Default value is 0.1

|

|

|

Skew Term

|

Yes or No

|

Refers to the links between diagonally connected cells in the Mesh. While potentially slowing down the calculation, these terms typically offer negligible improvement in the solution. By default, they are not used in the solution of the Turbulence module, but can be activated using the Skew Term option. In the Properties panel you can activate Skew Term for Turbulent Kinetic Energy and the Turbulent Energy Dissipation Rate solution for the Turbulence module.

|

Heat Numerics

Numerics under the Heat module refers to parameters and models used to control the numerical solvers for the energy equation. Numerical options are set or selected for the Heat module in the Properties panel.

|

Heat Module Numerics Options

|

Values

|

Description

|

|---|---|---|

|

Time Accuracy

|

Appears when the Common module entity in the Properties panel Time Definition is set to Transient. Select the Heat module and in the Properties panel > >

|

|

|

First Order

|

Default value for Time Accuracy. Determines temporal updates implicitly, based on the previous time step only.

|

|

|

Second Order

|

Determines temporal updates implicitly, based on the previous two time step. The relative influence of the two previous time steps depends on the Time Blending Factor and a Blending Options (Everywhere or. Boundary Only) with reference to location.

|

|

|

Crank/Nicolson

|

Determines temporal updates based on the previous time step alone, using a combination of an explicit or implicit formulation. The relative influence of implicit versus explicit depends on the Time Blending Factor and a Blending Options (Everywhere or. Boundary Only) with reference to location.

|

|

|

Relaxation

|

Controls the amount of correction applied during each iteration, using the following formula for Pressure and Velocity corrections:

Formula for enthalpy “h” corrections  |

|

|

Diagonal Relaxation

|

0.3, 0.3

|

Form of relaxation applied to the diagonal of the solution matrix. It has a similar effect to the influence of an old value at a previous time step.

|

|

Numeric Scheme

|

Properties panel: > > >

|

|

|

Upwind

|

Defaults to the fluid phase

|

|

|

Central

|

Applicable to the fluid phase only. In the solid phase, the Central option is used exclusively by default. If central option is selected, then the default values for Blending factor and Bounded Scheme are 0.1 and BC only respectively.

|

|

|

2nd Order Upwind

|

Applies to the fluid phase only.

|

|

|

Linear Solver

|

CGS

|

|

|

AMG

|

Default for the Energy solution

|

|

|

Sweeps

|

Default for Sweeps is 50 for the solution of the heat equations.

Number of Sweeps used for a given iteration appear in the *.out file as follows:

• INFO(Sim01:Heat): Heat

• INFO(Sim01:Heat:T:AMG): Residual: 0.000775839 Sweeps = 1

|

|

|

Linear Solver Tolerance

|

Default linear solver tolerance for the energy equation is 0.1.

Residuals for the heat module appear in the *.out file as follows:

• INFO(Sim01:Heat): Heat

• INFO(Sim01:Heat:T:AMG): Residual: 0.000775839 Sweeps = 1

Residuals above are normalized relative to the first iteration at the start of the timestep or steady-state simulation. They are not the residual within the linear solver.

|

|

|

Temperature Upper Limit

|

6000

|

|

|

Temperature Lower Limit

|

0.1

|

|

|

Max. Temperature Adjustment

|

50

|