Perform Generative Design Topology Optimization

Topology optimization evaluates single generative design iterations. The goal of the optimization is to achieve the best possible design relative to the defined set of criteria and constraints. These generative iterations are evaluated locally on your computer optimizing material layout within the specified design space, based on the set of loads and constraints defined for the system. These topology-optimized iterations are treated as CAD geometry for designers. The generative engine evaluates for different manufacturing requirements, such as CNC, molds, castings, forgings, and additive manufactured parts.

After the generative design study is fully defined,  Optimize is available. Click

Optimize is available. Click  Optimize to run topology optimization on your model. To view the optimization results in the graphics window, click

Optimize to run topology optimization on your model. To view the optimization results in the graphics window, click  Display Generative Result from the graphics toolbar. If you do not select

Display Generative Result from the graphics toolbar. If you do not select  Display Generative Result, the results do not appear in the graphics window, but optimization continues in the background.

Display Generative Result, the results do not appear in the graphics window, but optimization continues in the background.

Optimize is available. Click

Optimize is available. Click  Optimize to run topology optimization on your model. To view the optimization results in the graphics window, click

Optimize to run topology optimization on your model. To view the optimization results in the graphics window, click  Display Generative Result from the graphics toolbar. If you do not select

Display Generative Result from the graphics toolbar. If you do not select  Display Generative Result, the results do not appear in the graphics window, but optimization continues in the background.

Display Generative Result, the results do not appear in the graphics window, but optimization continues in the background.In the graphics window, the color of the model indicates the optimization status as follows:

• Blue—Optimization is in progress.

• Green—Optimization is completed and the result is fully converged.

• Yellow—Optimization is completed; however, the result did not converge.

In the graphics window, you can see the following statistics:

•  —Study not fully defined

—Study not fully defined

—Study not fully defined

—Study not fully defined•  —Study fully defined

—Study fully defined

—Study fully defined

—Study fully defined•  —Study calculation in progress

—Study calculation in progress

—Study calculation in progress

—Study calculation in progress•  —Study calculation finished successfully

—Study calculation finished successfully

—Study calculation finished successfully

—Study calculation finished successfully•  —Study calculation finished with issues

—Study calculation finished with issues

—Study calculation finished with issues

—Study calculation finished with issues•  —Study calculation failed

—Study calculation failed

—Study calculation failed

—Study calculation failed•  —Active design criteria for the study

—Active design criteria for the study

—Active design criteria for the study

—Active design criteria for the study•  —Active material for the study

—Active material for the study

—Active material for the study

—Active material for the study•  —Mass of the iteration

—Mass of the iteration

—Mass of the iteration

—Mass of the iteration•  —Size of the mesh elements and the number of elements in the model in bracket

—Size of the mesh elements and the number of elements in the model in bracket

—Size of the mesh elements and the number of elements in the model in bracket

—Size of the mesh elements and the number of elements in the model in bracketMove the pointer over the icons to view tooltips indicating the status with critical information. |

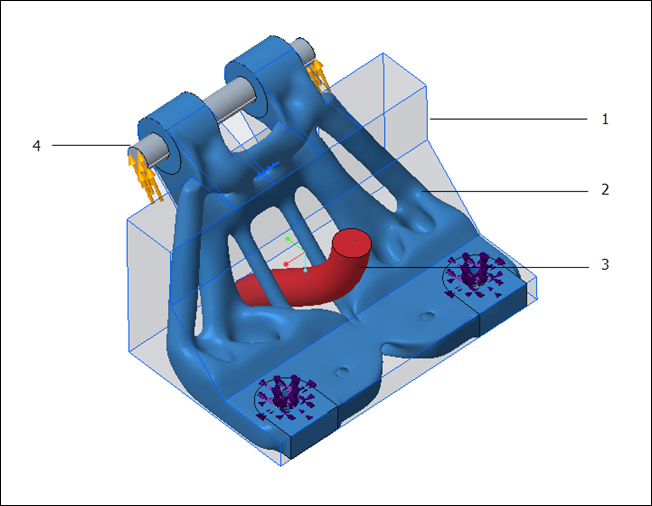

The following image shows a model that is being optimized:

1. Starting geometry

2. Preserved geometry and optimized model

3. Excluded geometry

4. Undesignated body

If you change the study parameters, such as forces, design spaces, active manufacturing method, or model geometry while optimization is in progress, it is stopped. Click  Optimize to restart optimization with new parameters as input.

Optimize to restart optimization with new parameters as input.

Optimize to restart optimization with new parameters as input.

Optimize to restart optimization with new parameters as input.If you exit the Generative Design application, optimization pauses. If you exit Creo Parametric before the optimization results converge, progress is not saved and you need to restart optimization.

If you exit the Generative Design application without creating a Generative Design feature, the optimization stops but all calculations and visual representations up until that point are saved. When you re-enter the application, the optimization pauses.

You can set Creo Parametric to start optimization automatically as soon as a study is defined by setting the configuration option generative_auto_optimization to yes. |