About Predefined Constraint Sets

Predefined constraint sets define the movement of a component in an assembly. A predefined constraint set contains constraints that define a type of connection, with or without a motion axis. Connections define a particular type of motion. After you decide which connection allows the type of motion you want, select it from the list and appropriate constraints appear. These constraints cannot be deleted, changed, or removed. New constraints cannot be added. A unique icon  is used in the Model Tree to indicate a component that is placed with predefined constraint sets.

is used in the Model Tree to indicate a component that is placed with predefined constraint sets.

is used in the Model Tree to indicate a component that is placed with predefined constraint sets.

is used in the Model Tree to indicate a component that is placed with predefined constraint sets.The Rigid, Weld, User-Defined, Ball, and Gimbal predefined sets do not have motion axes. The Ball and Gimbal constraint sets have motion, but have no axis.

All predefined constraint sets are editable in Mechanism Design. For more information search the Help Center.

Select the motion axis in the Navigation and Collection area. The Motion Settings Properties area appears for you to specify motion axis properties.

Set Types

Components placed with predefined constraint sets are underconstrained by intent to retain one or more degrees of freedom. After configuring a predefined constraint set, drag the component to ensure that it is placed correctly to allow the desired motion.

• Rigid—Connects two components so that they do not move relatively to each other. They are constrained with any valid set of constraints. Components so connected become a single body. Rigid connection set constraints are similar to a user-defined constraint set.

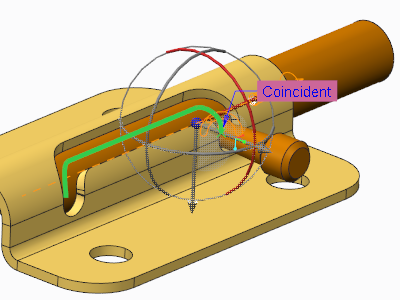

• Pin—Connects a component to a referenced axis so that the component rotates or moves along this axis with one degree of freedom. Select an axis, edge, curve, or surface as an axis reference. Select a datum point, vertex, or surface as a translation reference. A Pin connection set has two constraints: axis alignment and coincident.

• Slider—Connects a component to a referenced axis so that the component moves along the axis with one degree of freedom. Select edges or aligning axes as alignment references. Choose surfaces as rotation references. A Slider connection set has two constraints: axis alignment and coincident to restrict rotation along the axis.

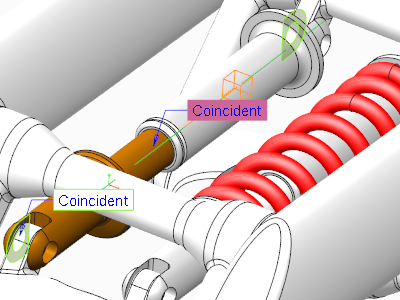

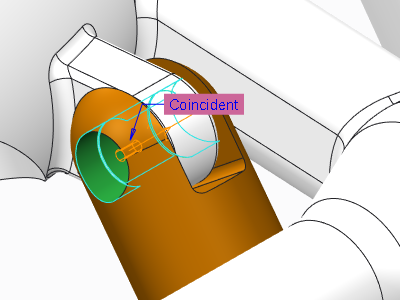

• Cylinder—Connects a component so that it moves along and rotates about a specific axis with two degrees of freedom. Select axes, edges, or curves as axis alignment references. A Cylinder connection set has one constraint.

• Planar—Connects components so that they move in a plane relatively to each other with two degrees of freedom in the plane and one degree of freedom around an axis perpendicular to it (arrows in the figure below). Select surface references for a coincident constraint. A Planar connection set has a single planar mate or align constraint. The mate or align constraint may be flipped or offset.

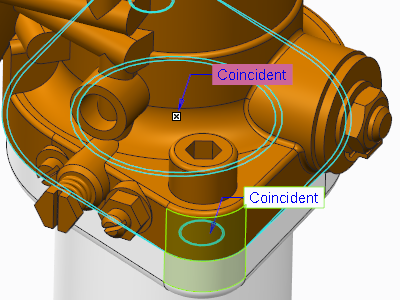

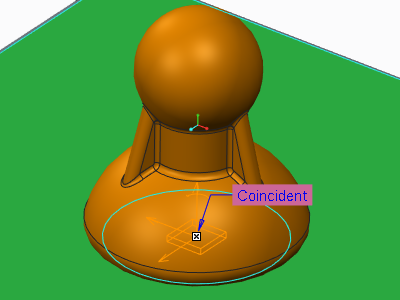

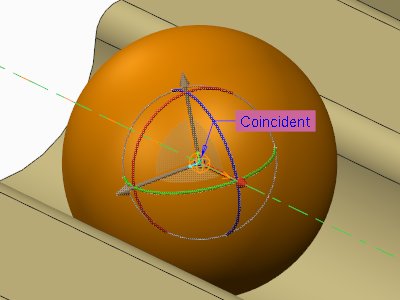

• Ball—Connects a component so that it can rotate in any direction with three degrees of freedom (360° rotation). Select points, vertex, or curve ends for alignment references. A Ball connection set has one point-to-point coincident constraint.

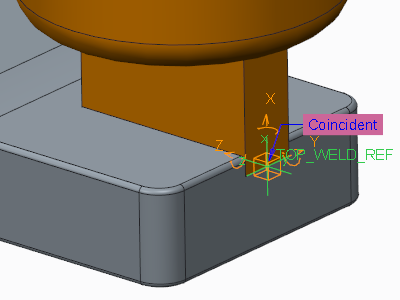

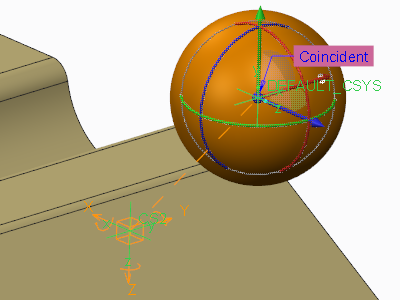

• Weld—Connects one component to another so that they do not move relatively to each other. The component is placed in the assembly by aligning the coordinate system of the component with a coordinate system in the assembly. The component can be adjusted using the open degrees of freedom in the assembly. A Weld connection has one coincident constraint for coordinate system alignment.

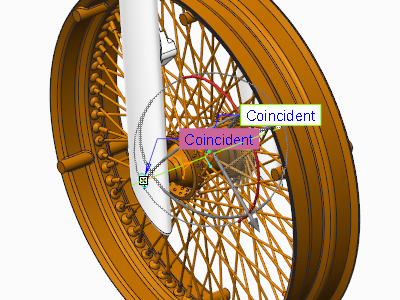

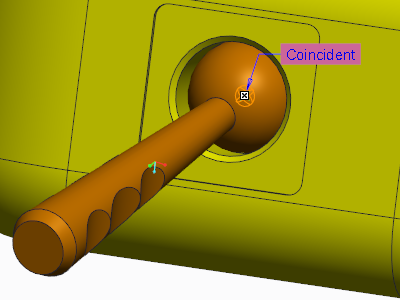

• Bearing—A combination of Ball and Slider connections with four degrees of freedom. There are three degrees of freedom (for 360° rotation) and movement along a referenced axis. For the first reference choose a point on the component or the assembly. For the second reference choose an edge, axis, or curve on the assembly or the component. The point reference can rotate freely about the edge and move along its length. A Bearing connection has one point-on-edge coincident constraint.

• General—Has one or two configurable constraints that are identical to those in a user-defined set. Tangent, point on curve, and point on nonplanar surface cannot be used for a General connection.

• 6DOF—Does not affect the motion of the component in relation to the assembly because no constraints are applied. The coordinate system of the component is aligned to a coordinate system in the assembly. The X, Y, and Z assembly axes are motion axes allowing rotation and translation.

The X, Y, and Z assembly axes are motion axes allowing rotation and translation. The 3 translation DOFs are independent. Only the x-axis rotation DOF is independent. The y-axis is dependent on the x-axis, you can lock the x-axis, with a servo motor, for independent rotation of the y-axis. The z-axis depends on both the x-axis and y-axis. Both the x-axis and the y-axis must be locked to have clear z-axis rotation.

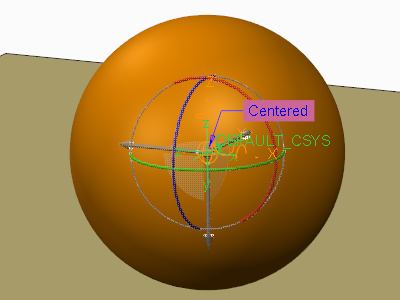

• Gimbal—A pivot joint with one centered constraint. The coordinate systems centers are aligned, but not the axes to allow free rotation.

• Slot—A point on a nonstraight trajectory. This connection has four degrees of freedom, where the point follows the trajectory in three directions. Choose a point on the component or the assembly for the first reference. The referenced point follows the non-straight reference trajectory. The trajectory has endpoints that are set when the connection is configured. A Slot connection has a single point alignment to multiple edges or curves constraint.