Weld Feature

You can add welds that were created using the Creo Parametric Welding application to your model, using one of the following methods:

• Manually create a weld feature weld by selecting Weld Feature as the weld type on the Weld Definition dialog box

You can use weld features in solid and midsurface compressed models to establish connectivity. The following types of welds created using the Creo Parametric Welding application can be used to create a simulation weld feature object:

• All solid welds created using the Welding application.

• Surface welds of type fillet or groove.

|

|

Lightweight welds are not supported.

|

During meshing, solid elements are created for solid weld objects while surface weld objects are compressed to shells as shown in the Fig 2. If the same model is compressed to a midsurface, the boundaries of the weld features are extended and projected and imprinted on the midsurfaces of the model. The weld connections are then recreated on the midsurfaces between these “projected” boundaries. For example, in Fig 3 below, the curves defining the fillet weld boundaries are projected to the midsurfaces (for both surface and solid welds), and the new fillet welds are created between the midsurfaces.

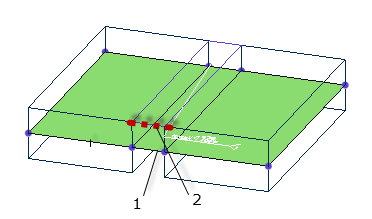

Fig 1. 1. surface fillet weld 2. solid fillet weld |

Fig 2. 1. surface fillet weld compressed to a shell 2. solid fillet weld meshed with solid elements |

Fig 3. 1. Model midsurfaces 2. New projected fillet weld elements |

Edge curves defining surface groove welds too are projected on the midsurfaces. A new surface is created between the midsurfaces. The following diagram illustrates this. In this example, the midsurfaces are assumed to be aligned. The weld surface partially overlaps these midsurfaces. If midsurfaces are not aligned, the weld surface connects imprints of the original weld edges on midsurfaces.

1. Original groove weld surface 2. Model midsurfaces 3. Projected groove weld surface |

1. New groove weld surface 2. Original groove weld surface |

When surface weld feature weld connections are used in solid model compression the original quilt surfaces are used for placing shell elements.