To Set Intermittency Options

You can create intermittent welds for fillet welds, groove welds, or butt welds.

1. With the Fillet Weld, Groove Weld, or Butt Weld tab open, click the Intermittency tab.

2. To make the weld intermittent, select the Intermittent weld check box.

3. To set the intermittency type, next to Type, select an option:

◦ Linear—Use linear pitch (distance between weld segments).

◦ Angular—Use angular pitch (angle between weld segments).

4. To set the method of determining the spacing between the intermittent weld segments, next to Pitch, select an option:

◦ Automatic—Calculates the pitch automatically. Then do the following:

1. To define the intermittent weld segment length, in the weld segment value box, type a value.

▪ For linear pitch, type a length value.

▪ For angular pitch, type a value in degrees.

2. To define the number of weld segments to create, next to Number of welds, type a value.

3. To set the method of distributing the intermittent weld segments along the trajectory, next to Weld spacing, select an option:

▪ End with gap—Distribute the weld segments so every weld is followed by a gap. There is a weld at the start of the trajectory, and a space at the end. The gap length is automatically adjusted to fit.

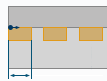

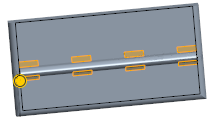

Linear:

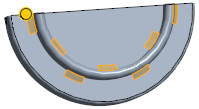

Angular:

▪ End with weld—Distribute the weld segments symmetrically from the middle of the trajectory, with a weld at the start of the trajectory, and a weld at the end. The gap length is automatically adjusted to fit.

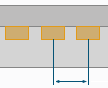

Linear:

Angular:

◦ By value—Defines the pitch by using a value. Then do the following:

1. To define the intermittent weld segment length, in the weld segment value box, type a linear length value, or an angular value in degrees.

2. To define the pitch, in the pitch value box, type a linear length value, or an angular value in degrees.

▪ ANSI—Pitch is measured from the middle of one weld segment to the middle of the next weld segment.

▪ ISO—Pitch is measured from the end of one weld segment to the beginning of the next weld segment.

3. Optionally, to define the number of weld segments created, select the Number of welds check box, and then type a value. If this check box is not selected, then welds are created along the entire length of the trajectory.

5. For double-sided intermittent welds, to stagger the weld segments so a weld segment on one side is across from a gap on the other side, select Staggered.

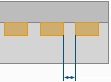

Linear staggered:

Linear not staggered:

Angular staggered:

Angular not staggered: