Creating High Speed Rest Rough Sequence

1. Click > . The HSM Rest Rough tab opens.

2. Click  and create a 8X2 BULL_MILL tool with a cutter diameter of 8 mm.

and create a 8X2 BULL_MILL tool with a cutter diameter of 8 mm.

and create a 8X2 BULL_MILL tool with a cutter diameter of 8 mm.

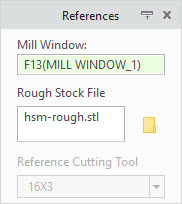

and create a 8X2 BULL_MILL tool with a cutter diameter of 8 mm.3. On the References tab, in the Rough Stock File collector, click  to import the rough stock file. The Open dialog box opens.

to import the rough stock file. The Open dialog box opens.

to import the rough stock file. The Open dialog box opens.

to import the rough stock file. The Open dialog box opens.4. Select hsm-rough.stl and click Open.

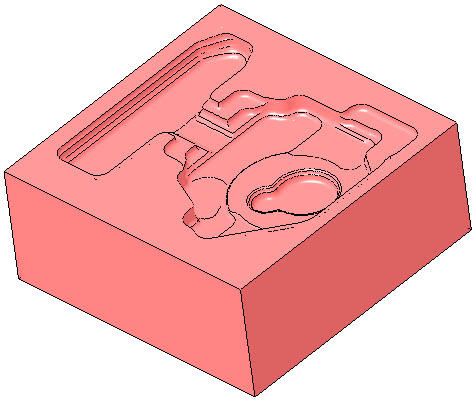

5. On the Parameters tab, the parameters are populated automatically, based on the tool diameter. To optimize the toolpath, set values as shown for the following parameters:

◦ FEED_UNITS = MMPM

◦ STEP_OVER = 3

◦ ROUGH_STOCK_ALLOW = 0.3

◦ MAX_STEP_DEPTH = 3

◦ SPINLDE_SPEED = 6000

6. Click the arrow next to  and then click

and then click  . The Material Removal tab opens.

. The Material Removal tab opens.

and then click

and then click  . The Material Removal tab opens.

. The Material Removal tab opens.7. On the Material Removal tab, click > . The Load stock dialog box opens.

8. Select hsm-rough.bin and click Open.

9. Click  to play the simulation. The Play Simulation dialog box opens.

to play the simulation. The Play Simulation dialog box opens.

to play the simulation. The Play Simulation dialog box opens.

to play the simulation. The Play Simulation dialog box opens.10. On the Material Removal tab, in the Stock Display list, select Sequence.

11. In the Play Simulation dialog box, click Sequence List to expand it. In the sequence list, double-click the color palette and set a new color that contrasts with the stock color.

12. Click  to play simulation.

to play simulation.

to play simulation.

to play simulation.

13. On the Material Removal tab, click > to open the Save current stock dialog box.

14. In the File Name box, type hsm-rest-rough.bin and click Save. This file will be used in the subsequent finishing material removal simulation.

15. On the Material Removal tab, click  and then on the HSM Rest Rough tab, click OK to complete the sequence.

and then on the HSM Rest Rough tab, click OK to complete the sequence.

and then on the HSM Rest Rough tab, click OK to complete the sequence.

and then on the HSM Rest Rough tab, click OK to complete the sequence.