About the Profile Rib Feature

A profile rib feature is a thin fin or web protrusion that attaches to solid surfaces in a part. Profile ribs are usually designed to strengthen parts, and to prevent unwanted bending. They are often used between two perpendicular surfaces.

You create a profile rib by sketching the feature cross-sectional sketch between two surfaces, or by selecting an existing sketch.

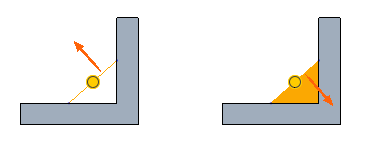

Next, you define the direction for creating the profile rib geometry, on one side of the sketch or the other side. The sketch and the reference surfaces must form a closed area for the rib to fill.

Then you define a width for the rib, and place the rib geometry in relation to the sketching plane, either on one side of the plane, or symmetrical about the plane.

You can create a profile rib between two straight surfaces.

You can also create a profile rib when one or both reference surfaces are revolved. In this case, the angled surface of the rib is conical, not planar. The section revolves about the axis of the parent feature. The rib geometry is trimmed with two planes parallel to the sketching surface. The distance between the planes corresponds to the width of the rib and attaching geometry.