Multicomponent Mixing using a Nozzle: Exercise 1—Extracting the Fluid Domain

Fluid domain extraction is the creation of a closed geometric region that surrounds the fluid.

1. Click Home > Select Working Directory and navigate to the Advanced_FlowAnalysisModels folder. Click OK.

2. Click

File >

Open

Open.

3. From the File Open dialog box, browse to the Multi-component-mixing folder and select MIXING_NOZZLE.asm. Click Open.

4. Click

in the Graphics toolbar to display the style elements. Select

Shading

Shading, or

Shading with Edges

Shading with Edges.

5. Click the Applications tab.

6. Click

Flow Analysis

Flow Analysis. The

Flow Analysis tab opens.

7. Click

New Project

New Project. If the Residual plot opens, close it.

8. Click

Create Fluid Domain

Create Fluid Domain. The

Fluid Domain Creation tab opens.

9. Click the Openings tab.

10. Click the Faces box. The Surface Sets dialog box opens.

11. In the Surface Sets dialog box, under Included surfaces right-click all the surfaces and click Remove All.

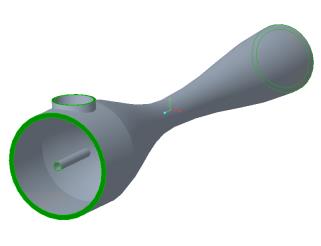

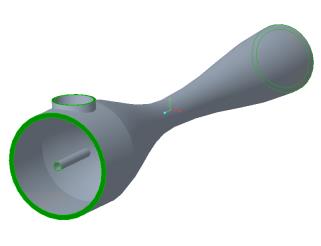

12. In the graphics window, press CTRL and select the four surfaces shown below. Four surfaces appear in the

Surface Sets dialog box, under

Included surfaces.

13. Click OK.

14. In the

Fluid Domain Creation tab click

to create the fluid domain.

Splitting the Boundary

1. In the Model Tree, right-click MIXING_NOZZLE_1_FLUID.PRT.

2. Click

. The part opens in a new window. Make this the active window.

3. In the MIXING_NOZZLE_1_FLUID.PRT window, click the Editing list.

4. Click

Split Surface

Split Surface.

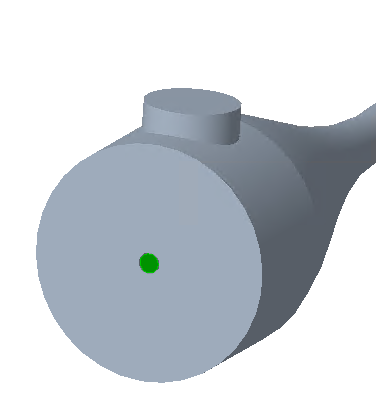

5. In the Split Surface tab, click Placement.

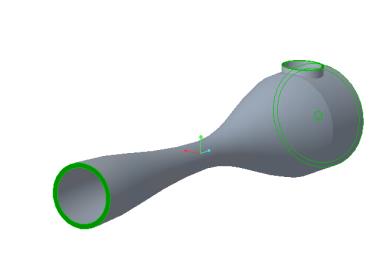

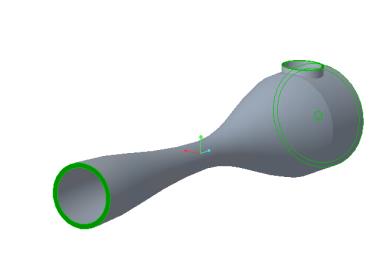

6. Select the nozzle opening as shown below.

7. Click the

Selected contours box and select the fuel pipe opening as shown below.

8. Click

.

9. In the

Operations group, click

Regenerate

Regenerate. Toggle to the assembly in the window.

Adding the Simulation Domain

1. In the

Simulation Domains group, click

Select Simulation Domains

Select Simulation Domains.

2. Click Add fluid domain.

3. In the Model Tree, select MIXING_NOZZLE_1_FLUID.PRT and click OK.

4. MIXING_NOZZLE_1_FLUID.PRT appears in the Model Tree. Boundaries for the boundary conditions

BC_1,

BC_2,

BC_3, and

MIXING_NOZZLE_1_FLUID are created automatically. They appear in the Flow Analysis Tree under

Boundary Conditions

Boundary Conditions >

General Boundaries

General Boundaries Adding and Renaming Boundaries

1. Under Domains, select MIXING_NOZZLE_1_FLUID.

2. In the

Operations group, click

Add Boundary Condition

Add Boundary Condition. The

Surface Sets dialog box opens.

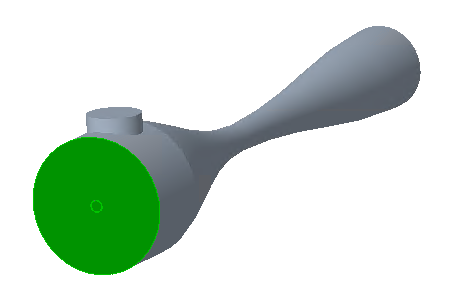

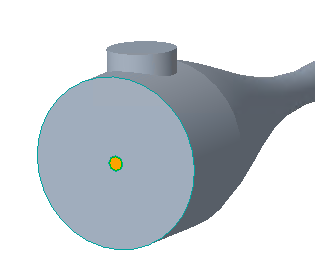

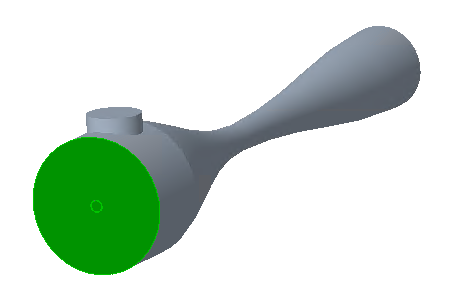

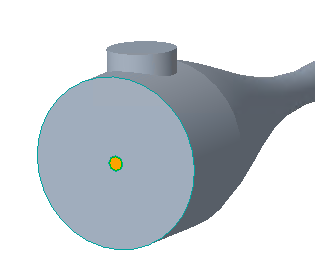

3. In the graphics window, select the fuelpipe opening shown below.

4. In the Surface Sets dialog box, click OK. BC_4 appears under General Boundaries in the Flow Analysis Tree

5. Click OK.

6. In the Flow Analysis Tree under

Boundary Conditions

Boundary Conditions >

General Boundaries

General Boundaries, right-click

BC_1 and select

Rename

Rename.

7. In the

New name box, type

Nozzle_Outlet and click

.

8. In the Flow Analysis Tree under

Boundary Conditions

Boundary Conditions >

General Boundaries

General Boundaries, right-click

BC_2 and select

Rename

Rename.

9. In the

New name box, type

Nozzle_Side_Inlet and click

.

10. In the Flow Analysis Tree under

Boundary Conditions

Boundary Conditions >

General Boundaries

General Boundaries, right-click

BC_3 and select

Rename

Rename.

11. In the

New name box, type

Nozzle_Inlet and click

.

12. In the Flow Analysis Tree under

Boundary Conditions

Boundary Conditions >

General Boundaries

General Boundaries, right-click

BC_4 and select

Rename

Rename.

13. In the

New name box, type

Fuelpipe_Inlet and click

.

Open.

Open. Open.

Open. Open.

Open. in the Graphics toolbar to display the style elements. Select

in the Graphics toolbar to display the style elements. Select  Shading, or

Shading, or  Shading with Edges.

Shading with Edges. Flow Analysis. The Flow Analysis tab opens.

Flow Analysis. The Flow Analysis tab opens. New Project. If the Residual plot opens, close it.

New Project. If the Residual plot opens, close it. Create Fluid Domain. The Fluid Domain Creation tab opens.

Create Fluid Domain. The Fluid Domain Creation tab opens.

to create the fluid domain.

to create the fluid domain. . The part opens in a new window. Make this the active window.

. The part opens in a new window. Make this the active window. Split Surface.

Split Surface.

.

. Regenerate. Toggle to the assembly in the window.

Regenerate. Toggle to the assembly in the window. Select Simulation Domains.

Select Simulation Domains. Boundary Conditions >

Boundary Conditions >  General Boundaries

General Boundaries Add Boundary Condition. The Surface Sets dialog box opens.

Add Boundary Condition. The Surface Sets dialog box opens.

Boundary Conditions >

Boundary Conditions >  General Boundaries, right-click BC_1 and select

General Boundaries, right-click BC_1 and select  Rename.

Rename. .

. Boundary Conditions >

Boundary Conditions >  General Boundaries, right-click BC_2 and select

General Boundaries, right-click BC_2 and select  Rename.

Rename. .

. Boundary Conditions >

Boundary Conditions >  General Boundaries, right-click BC_3 and select

General Boundaries, right-click BC_3 and select  Rename.

Rename. .

. Boundary Conditions >

Boundary Conditions >  General Boundaries, right-click BC_4 and select

General Boundaries, right-click BC_4 and select  Rename.

Rename. .

.