Common Error and Warning Messages

While working in Creo EZ Tolerance Analysis, you might encounter some messages or graphical icons that indicate warnings or errors with the defined Stackups. The following sections describe the common errors and warnings and provide guidance on how to resolve them.

Potentially Significant 3D effects

Creo EZ Tolerance Analysis is specifically designed to solve 1-dimensional (1D) Stackup problems, but not 2- or 3-dimensional (2D or 3D) Stackup problems. See the1D vs 2D and 3D Problemssection for more details.

However, Creo EZ Tolerance Analysis can, often recognize that the defined Stackup may be ignoring some 2D or 3D effects. In such cases, you get a warning about the defined 1D Stackup that may benefit from being evaluated with a 2D or 3D tolerance Stackup method using a 3D tolerance analysis tool.

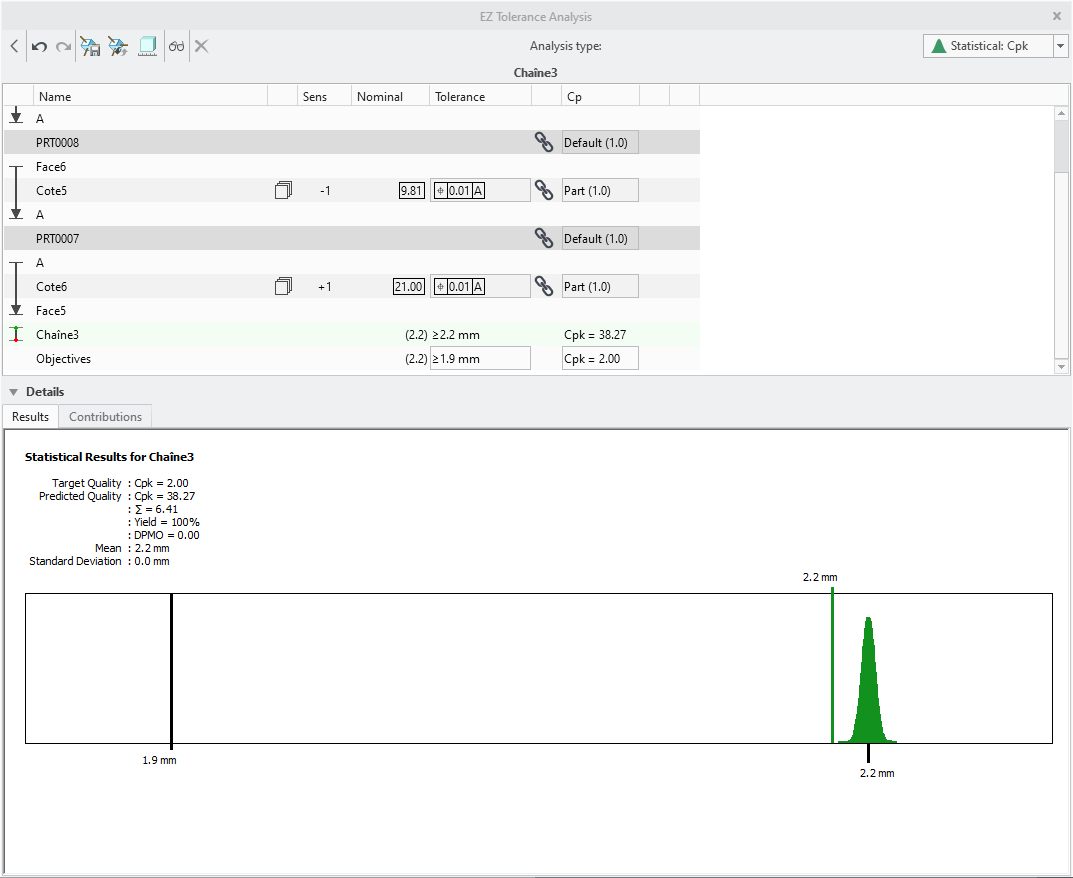

In the summary view of theStackup Tablea small yellow triangle warning glyph on the lower right of the icon indicates whether the objectives of the Stackup have been met  or not met

or not met  . The presence of this warning glyph indicates that the analysis results are ignoring potentially significant 3D effects.

. The presence of this warning glyph indicates that the analysis results are ignoring potentially significant 3D effects.

or not met

or not met  . The presence of this warning glyph indicates that the analysis results are ignoring potentially significant 3D effects.

. The presence of this warning glyph indicates that the analysis results are ignoring potentially significant 3D effects.You will also see a warning icon and a message regarding the potential 3D effects on the Stackup results graph:

While not all cases are detected, here are the scenarios where the notifications appear:

• When the surfaces that define the critical Stackup distance do not overlap.

• When some of the assembly constraints between parts are outside the coverage for the surfaces selected for the critical Stackup distance.

• When the size of the surfaces constraining the parts to one another are significantly smaller than the surface involved in the Stackup distance definition.

• When a part is attached with a pattern of two or more fasteners, and the measurement direction is in the plane of the mating faces to a surface that is outside of the pattern.

Creo EZ Tolerance Analysis may flag Stackups that truly can be modeled with a 1D method. The most common situation when this occurs is when several equivalent assembly constraints are present between parts in the assembly. For example, a shaft mounted on each end into a bearing or bushing, or a circuit board mounted on several standoffs with multiple fasteners. These Stackups are flagged because the 1D Stackup definition involves the creation of a single— dimension loop through the parts, while the other constraints that help to stabilize the part in the assembly are not included in the Stackup definition. The flag is a warning message about considering the relationship between the parts and assessing whether modeling a more advanced 3D tolerance analysis tool like CETOL 6σ from Sigmetrix is required.

Missing or Invalid References

Creo EZ Tolerance Analysis maintains references to geometric features in the Creo models and re-evaluate these references whenCreo EZ Tolerance Analysis is opened. If the model geometry has changed such that a particular geometric reference cannot be found when opening Creo EZ Tolerance Analysis, an error message alerts you and suggests the tools for repairing the invalid references.

The following types of geometric references that are maintained by Creo EZ Tolerance Analysis which may become missing or invalid:

• Components whose features are used in the Stackup

• Start or End feature for the Stackup measurement

• Annotation plane reference

• Assembly constraint features (mating faces)

• Features added to parts

Invalid References Dialog

If any missing or invalid references are detected while opening Creo EZ Tolerance Analysis, the Invalid References dialog box opens.

This dialog box lists the items with missing or invalid references and provides a brief instruction on how to resolve them.

In some cases, the Stackup will not be repairable using the tools within Creo EZ Tolerance Analysis. The two cases where the Stackup cannot be repaired are:

• A component refenced by the Stackup is missing.

• A feature referenced by the Stackup is still present in the model, but its orientation is no longer valid with respect to the Stackup direction.

In these cases, if the condition cannot be resolved outside of Creo EZ Tolerance Analysis, for example, by restoring a missing component, then the Stackup may be deleted.

Error and Warning Icons in the Stackup Table

Any Stackups in the model that are impacted by invalid references are identified in the summary view of theStackup Tableby an error icon, and the Stackup name is shown in bold red text. Additionally, the nominal value and results show as N/A, indicating that the results cannot be calculated due to the invalid references.

When you switch to the detail view for one of the impacted Stackups, the error icons in the left side column indicate the parts and features that are impacted by the invalid references. The error iconindicates the primary item with an invalid reference. In most cases, this is the item that can be repaired to resolve the problem.

The warning iconis shown on the Stackup results row toindicate that the Stackup results cannot be calculated until the invalid references have been resolved.

Since the Stackup results cannot be calculated, the results graph and the contributions table are not displayed in the area below theStackup Table. Instead, a warning message indicates that the results cannot be calculated and list the items that need repair. The items in the list can be clicked to open the repair tool for that item.

Repairing an Invalid Reference

To repair a failed reference, either right-click on the row in theStackup Tableand chooseRepairfrom the pop-up menu, or select the item in Results or Contributions tabs below the table.

Creo EZ Tolerance Analysis opens the Repair Feature dialog box and updates the model display to make it easier to select the new reference. The part whose feature is being repaired is shown shaded, the parts that are not involved in the Stackup are hidden, and the other parts of the Stackup are shown dimmed.

After selecting the replacement reference, clickOK in the dialog box.

You can then select the next feature to be repaired. If this is the last feature to be repaired, Creo EZ Tolerance Analysis automatically recalculates the Stackup results and presents the Results graph and Contributions table.

In cases where the invalid reference is the annotation plane reference, there is no feature in the Stackup table in need to repair, so you will need to select the item in the Results or Contributions tabs to activate the Repair dialog box. |