Configurations Options for Creo NC

add_multax_on_before_defsub

no*, yes

yes—Adds MULTAX/ON in DEFSUB for the NC subroutine.

allow_mfg_in_assem_mode

yes, no*

Allows you to open a manufacturing model in assembly mode:

yes—Adds the Open in Assembly mode option to the list in the File Open dialog box when you click the arrow next to Open.

allow_safety_rad_over_prt_accu

no*, yes

yes—Considers the safe radius while generating the toolpath in Milling NC sequences, even if that radius is less than the part accuracy.

allow_workpiece_silhouette

no*, yes, auto

Specifies which model is used for creating a Silhouette Mill Window:

• no—The system creates the window by using the silhouette of the reference part. If the manufacturing assembly contains more than one reference part, you have to select which part to use for creating the silhouette. You can not select a workpiece.

• yes—The system allows you to use both reference parts and workpieces to create a Silhouette Mill Window. You have to select which part to use.

• auto—If the manufacturing assembly contains only one workpiece, the system automatically uses it to create the silhouette. If there are multiple workpieces, you have to select which one to use. You can not select a reference part, unless there are no workpieces present in the manufacturing assembly.

arc_radius_limit

Sets the upper limit for a radius in a CIRCLE statement of NCL file. The value must be positive. If not, 10*part_size is considered. The default is -1.

|

|

If the radius value associated with the CIRCLE command is less than the specified value of arc_radius_limit, the CIRCLE statement is output in the NCL file.

If the radius value associated with the CIRCLE command is more than the specified value of arc_radius_limit, multiple GOTO points are output in the NCL file instead of the CIRCLE statement.

|

assy_mfg_open_mode

mfg, process, feature, any_mode*

Specifies the way of opening manufacturing models:

• mfg—Open using the Assembly Creo NC application.

• process—Open using the Manufacturing Process Planning for Manufacturing application.

• feature—Open using the Expert Machinist application.

• any_mode—Open using the available license. For example, open the model in Assembly Creo NC application if you have the license for this application.

Once the model is open, you can switch between applications by using the Applications option on the top menu bar.

autodrill_udf_dir

<directory name>

The default directory for storing the Hole Strategies that are used in Auto Drilling. Use the full path name to avoid problems.

autodrilling_config_filename

<file name>

Retrieve automatically and load the configuration file for the auto-drilling table.

autodrilling_holestyle_param

<user defined parameter name>

Parameter name included in hole features of a manufacturing reference model. The parameter value identifies the MUDF for holemaking that is automatically applied in Creo NC to drill these holes.

back_drill_spndl_colnt_mtn

no*, yes

yes—Maintains the spindle and coolant statements in a systematic order with respect to the spindle orientation in the CL data, in Back-Drill NC sequence.

campost_dir

<directory name>

If the configuration option ncpost_type is set to ncpost, the campost_dir configuration option specifies the CAM-Post load point directory to enable you directly set-up the post-processors and generate MCD files. Use the full path name to avoid problems.

chk_part_surfs_profpock

no*, yes

This option applies to gouge checking in Milling. Set this option to yes if you want the system to automatically include all reference part surfaces as Check Surfaces for Profiling and Pocketing NC sequences.

cl_arrow_scale

<positive number>

This option enables you to control the size of the tool path arrow when displaying the tool path for operations and NC sequences. The default is 1. If you set it to 0, the arrow does not display. If you specify any other positive number, the arrow scales accordingly.

cl_rotate_sign_convention

table*, tool

Defines the ROTATE sign direction convention with respect to either rotation table or cutting tool.

curve_traj_offset_opt_default

Enables default state of Offset Cut option for the trajectory sequence.

on—The Offset Cut option is selected.

off—The Offset Cut option is not selected.

auto*—The option state depends on the selected chain reference.

disable_custom_tool_prm_warning

no*, yes

Custom parameter file contains the definitions of parameters that you frequently use. Use the mfg_custom_tool_param_file or mfg_custom_sequence_param_file configuration options to specify the XML file in the local directory.

If the custom parameters file is missing or modified, error message is displayed with an option to keep the user-defined parameter definitions. By default, error messages are displayed whenever there are discrepancies in regards to the custom parameters file.

• no—Continue launching user interaction dialog when there is an error or change in the file that has user-defined tool parameters.

• yes—Disables launching user interaction dialog when there is an error or change in the file that has user-defined tool parameters.

disable_toollen_in_travel_envlp

no*, yes

yes—Adjusts the adapter and tool length with respect to the tool travel.

display_mfg_icon_for_mfg_assy

no*, yes

Displays manufacturing icons for manufacturing assembly files in File Open and Save dialog boxes:

• no—Display assembly icons for manufacturing assembly files.

• yes—Display manufacturing icons for manufacturing assembly files.

dm_nc_process

yes, no*

Automatically generates a .xml file with the process information when you save a manufacturing model in Creo Parametric. The .xml file is then automatically attached to the NC assembly CAD Document as its secondary content of category MPMLink Process Info. When you upload to Windchill the NC assembly CAD Document with the .xml file attached as its secondary content, MPMLink uses the process information in the .xml file to further define manufacturing processes. MPMLink uses the process information to create specific steps in a process plan or create resources for use in process plans

• yes—Generates the document whenever CAD document is saved.

• no—Does not generate the document.

enable_2x_traj_multi_loops

yes, no*

• yes—Allows selection of multiple loops on the selected surfaces in 2–Axis trajectory milling.

• no—Does not allow selection of multiple loops on surfaces.

enable_bld_oper_goto_pnt_fix

yes*, no

• yes—Enables tool motion according to the movement specified in the GOTO point for a manufacturing assembly containing a build operation.

• no—Enables only Simultaneous tool movement irrespective of the offset settings in the GOTO point for a manufacturing assembly containing a build operation.

enable_classic_strghtcut_srfml

yes, no*

yes—Enables the Straight Cut option in the classic Surface Milling NC sequence.

enable_clearance_plunge_fix

yes, no*

• yes—Avoids zero-length automatic plunge motions and corrects the connecting motions.

enable_cmm_refcsys_pprint_fix

yes*, no

By default, the CL data does not have PPRINT/DMIS text for setting up reference CSYS as a first step in an operation. Set it to yes if you want to output the PPRINT/DMIS text in the CL data.

The CL data will have the following lines for setting up reference CSYS:

• Sequence name

• Sequence comments

• Sequence type

• sequence ID applicable for reference CSYS

enable_cutcom_apprexit_fix

yes*, no

• yes*—Removes the GOTO commands in the CL data between the approach or exit chains and the cutting chains while the cutter compensation is specified.

• no—Keeps all GOTO commands in the CL data.

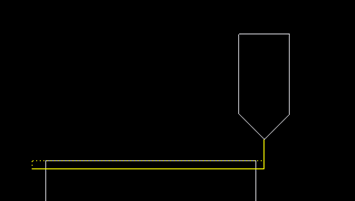

enable_cutcom_helix_corner

yes*, no

• yes*—The corner point of the linear helical chains is used in the cutcom output.

|

|

|

The enable_cutcom_helix_corner is set to no.

|

The enable_cutcom_helix_corner is set to yes.

|

enable_cutcom_plnr_apprexit_fix

yes*, no

• yes*—Removes the GOTO commands in the CL data between the approach or exit chains and the cutting chains while the cutter compensation for planar open loops is specified.

• no—Keeps all GOTO commands in the CL data.

enable_cutcom_rm_tiny_ents

yes*, no

• yes*—Removes the GOTOs by adjusting circle and line ents as long as the adjusted point or portion of ent is within the stock allowance region while the cutter compensation is on.

• no: Keeps all GOTO commands in the CL data.

enable_feed_rate_for_helix

yes*, no

• yes*—Outputs feed rate value for helical chain changes when ARC_FEED_CONTROL parameter is set to TOOL_PERIMETER.

enable_finishing_circ_record

yes—Generates circle records for finishing sequence profile cuts when the sequence parameter circ_interpolation is set to arc_only.

no*—Does not generate circle records.

enable_mfg_drill_tpath_fix

yes*, no

yes—Enables an improved combination of rules in Holemaking NC sequences.

enable_mfg_leadtilt_ang_fix

yes, no*

yes—Creates a toolpath with accurate tool tilt angle at the junctions of non-tangent toolpath segments.

no—Does not make any changes in the default tool tilt angle.

enable_mfg_reorder_regen_fix

yes, no*

yes—Reduces the regeneration time while reordering manufacturing features if tool relations are used to drive NC sequence parameters

enable_new_mfg_pat_inst_naming

yes, no*

yes—Outputs the name pattern instance in the NCL file and in the Model Tree in the <name of step instance-name of operation> format.

enable_offcrv_with_split_fix

yes*, no

yes—Improves the CUTCOM output for steps with open curve references.

enable_param_n_tool_upd_dialog

yes, no*

• yes—Opens a dialog box for modification of manufacturing parameters and tools during a paste special operation, and during UDF placement procedures.

• no—Does not open any dialog box for modification of tools and manufacturing parameters during a paste special operation, and UDF placement procedures.

enable_pprint_seq_comment_end

yes, no*

yes—If you specify comments for OPERATION_COMMENTS and NC_SEQUENCE_COMMENTS, COMMENTS END is added in the NCL file to indicate the end of an NC sequence and an operation comments.

enable_traj_2cntr_toolaxis_fix

yes*, no

• yes—Avoids flipping of tool axis direction in a two-contour trajectory sequence.

enable_traj_crvs_no_alt_refs

yes*, no

• yes—Does not replace the missing curve cut references with alternate references in a trajectory milling sequence.

• no—Replaces the missing curve cut references with alternate references, if available, in a trajectory milling sequence. You can manually select the missing curve references, if required.

enable_traj_fix_nrmsrf_axisdfs

yes*, no

yes—Enforces axis definitions specified by the normal surface references in a trajectory step.

gpostpp_dir

<directory name>

If the configuration option ncpost_type is set to gpost, the gpostpp_dir configuration option specifies the directory containing the post-processor files to be used by GPOST. Use the full path name to avoid problems.

grv_turn_bothdir_cutcom_output

yes, no*

• yes—In groove turning sequences, when the ALTERNATE_SIDE_OUTPUT parameter is set to yes, the CUTCOM OFF statement is output before the tool retracts from each side. The GOTO commands or points are output during all entry and exit motions.

• no—Does not output the CUTCOM OFF statement before the tool retracts from each side.

include_all_tools_in_list

yes, no*

Specifies whether tools for the current step and the active head on the machine tool are included in the tools list.

• yes—Includes all the available tools in the list.

• no—.Includes tools valid for the current step by default.

mfg_solid_tool_display

yes, no*

yes—Displays the corresponding solid tool used for the playpath when using the CL player.

mfg_udf_info_setup_file

<file name>

Enables you to specify the path to the Mfg criteria-UDF name mapping file. The manufacturing criteria functionality in the process table is available only if you specify the mfg_udf_info_setup configuration option.

mfg_areaturn_cutcom_each_slice

yes, no*

yes—The CUTCOM output for an Area Turning step is separate for each slice.

mfg_assign_param_formula

Specifies whether to set default values of manufacturing parameters by using XML-based formulas.

yes—Apply the default values of manufacturing parameters by using XML-based formulas.

no—Ignore the default values of manufacturing parameters by using XML-based formulas.

mfg_auto_ref_mfg_template

yes, no*

Specifies whether Creo NC must automatically assign references for steps created from a template. For example, if the template contains a reference coordinate system having a user-defined name as MYCSYS and if the manufacturing model also contains a coordinate system having a user-defined name as MYCSYS, Creo NC automatically assigns the reference.

• yes—Creo NC automatically assigns one or more of the following references from the template, as applicable:

◦ Coordinate system

◦ Retract surface

◦ Mill window

◦ Curve for Trajectory milling (2-axis)

◦ Mill surface

◦ Mill volume for Profile milling

◦ Drill group for Holemaking

Creo NC assigns the reference based on the name and the type.

• no—You must assign the geometric references for all steps created from a template. This is the default.

mfg_auto_ref_prt_as_chk_srf

yes*, no

This option applies to gouge checking in Milling. The system automatically includes all solid surfaces of all reference parts as Check Surfaces for Surface and 5-Axis Trajectory milling. To disable this functionality and select the Check Surfaces manually, set this option to no.

mfg_auto_retract_clear_dist

1.0, 0.005

1.0 if the length unit of the manufacturing template is mm.

0.005 if the length unit of the manufacturing template is inches.

The distance between the automatically created retract plane and the coordinate system of the step.

If a step that you extract to the process table cannot use the retract plane of the operation, Creo NC applies the value that you specify for the mfg_auto_retract_clear_dist configuration option to the step to create the step retract plane.

mfg_cdplayer_refresh_grscreen

yes, no*

yes—Refreshes the graphics screen. The Refresh Tool Display option becomes available in the View menu of the PLAY PATH dialog box.

mfg_circ_interpolate_gouge_fix

yes, no*

yes—Avoids gouges when CIRC_INTERPOLATE parameter is set to ARC_ONLY or ARC_AND_POINTS when the arc is helical.

mfg_clfile_excl_seq_warn

yes, no*

yes—Posts a warning while generating Operation output any of the steps are incomplete. The steps are excluded from the CL output. The Abort option is generated in the CL data output.

no—The warning about incomplete steps is not posted and the steps are not generated in the CL data output.

mfg_comp_auto_upd_chk_off

yes, no*

yes—Clears the Automatic Update intersection option while inserting a UDF into an NC assembly.

mfg_custom_sequence_param_file

<file name>

Specifies the location and name of the custom sequence parameter definition file. Use the full directory path and name.

mfg_custom_tool_param_file

<file name>

Specifies the location and name of the tool parameter definition file. Use the full directory path and name.

mfg_customize_dialog

yes*, no

yes—Uses the Customize dialog box for customizing NC Sequences.

no—Uses the old cascading menus.

mfg_cutlin_helix_norm_gouge_fix

yes*, no

yes—Avoids gouges in Cutline Milling sequences with closed cutlines when SCAN_TYPE is set to TYPE_HELICAL. Toolpath is created relative to surface normals when USE_SURF_NORMS parameter is used..

mfg_cutline_save_mesh

yes*, no

Specifies whether Creo NC stores the mesh generated by Creo Simulate along with the tool path or not. Creo NC uses the mesh to compute the tool path for Cut Line Surface Milling.

• yes—Creo NC checks whether a mesh has been stored with the NC sequence. If the mesh is valid, that is, the geometry has not changed since the earlier computation, Creo NC uses it to compute the tool path. If a mesh has not been stored or is not valid, a new mesh is generated and stored with the NC sequence. This is the default.

• no—A new mesh is always generated to compute the tool path. Creo NC ignores and deletes any stored mesh.

mfg_cycl_inherit_frm_site_tbl

yes, no*

yes—Inherits sequence parameters from the site table while switching the drill cycle in the Holemaking NC sequence.

mfg_deepgrv_turn_typ1_conn_fix

yes, no*

yes—Generates accurate groove turning toolpath by avoiding connection through rest material when SCAN_TYPE is set to TYPE_1_CONNECT.

mfg_disbl_clcmd_on_noncut_pass

yes,no*

yes—Enables CL commands for non-cut passes.

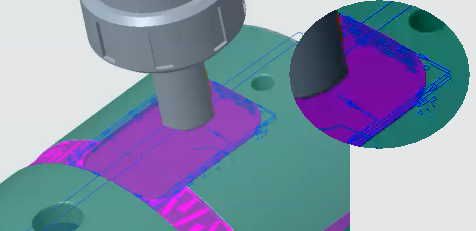

mfg_display_rework_corner

yes, no*

yes—Displays the remaining area while computing the tool path for corner finishing, thus enabling you to check your choice of the threshold angle. The steep and shallow areas are highlighted using separate colors.

no—Does not display the remaining area.

mfg_drill_axis_arrow_color

yes, no*

yes—Controls the color of axis arrow using the system color. After you set this option to yes, you can change the color of the arrow by changing the color of Selected category.

mfg_drill_cln_undesired_wp_dep

yes, no*

yes—While retrieving the manufacturing assembly, the drilling-sequence dependencies on the respective workpieces that are nor needed are removed keeping intact the needed dependencies.

no—All drilling sequence dependencies on the workpieces are kept intact while retrieving the manufacturing assembly.

mfg_drill_orient_along_ref_hole

yes, no*

yes—Changes the drilling tool direction to correct the orientation for concentric holes.

mfg_engrav_avoid_clines_tpath

yes*, no

yes—The engraving toolpath skips the geometry center lines.

no—The engraving toolpath calculates the geometry center lines.

mfg_finish_round_corner_fix

yes, no*

yes—Generates accurate and smooth toolpaths at the round corners in the finishing sequences.

mfg_groove_merge_colinear_pnts

yes, no*

yes—Outputs the first and last collinear GOTO points of the same feed for a groove turning sequence in the NCL file.

mfg_grvturn_same_toolwidth_Fix

yes, no*

yes—If a groove has the same width as tool width (considering the stock allowances), this option helps generate accurate groove turning toolpath to the bottom of the groove.

mfg_grvturn_sideturn_gouge_fix

yes, no*

yes—When SCAN_TYPE is set to SIDE_TURN, this option avoids gouge in groove turning by minimizing the side turn plunge.

mfg_grvturn_typ1_full_tpathfix

yes, no*

yes—Creates accurate toolpath in a groove turning sequence when the SCAN_TYPE parameter is set to TYPE_1 and the groove walls are angled.

mfg_grvturn_wall_colision_fix

yes, no*

yes—Avoids plunging in the rest material in groove turning sequences when SCAN_TYPE is set to TYPE_ONE_WALL.

mfg_ijk_num_digits

<integer number>

Sets the number of digits for i, j, k tool coordinates in a CL data file. The default is 10.

mfg_info_location

top_left*, bottom_right

Default position of the Manufacturing Info dialog box.

mfg_mill_window_depth_fix

yes, no*

yes—Ensures that the toolpath is accurately generated when you are using a mill window. The depth of a mill window is correctly assessed based on the reference normal direction.

mfg_millvol_outside_wp_fulltrim

yes*, no

yes—In Volume Milling sequences, when TRIM_TO_WORKPIECE parameter is set to FULL_TRIM, this option ensures that the toolpath is generated only if the mill volume intersects the workpiece.

no—Toolpath might get generated even when the mill volume does not intersect the workpiece.

mfg_modal_command_file

<file name>

Enables you to make some of the APTn index topics modal, which means that you repeatedly get a list of major keywords corresponding to this topic upon completing a command line.

mfg_new_cl_player_for_sync

yes*, no

yes—Enables the CL player for synchronized NC sequences.

mfg_ncseq_edit_performance_fix

yes, no*

yes—Optimizes the time required for editing the NC sequences. This option also optimizes the time required for editing the existing tool motions and creating new tool motions.

mfg_optimized_drill_toolpath

yes, no*

yes—Calculates optimum drill toolpath when SCAN_TYPE is set to SHORTEST.

mfg_output_same_feed_rate_hsm

yes, no*

yes—Outputs the feed rate statement in the NCL file, even if the first feed rate of the current HSM sequence is identical to the last feed rate of the previous HSM sequence.

mfg_param_auto_copy_from_tool

No*, All, Misc, Cutting

Specifies which are the tool parameters that are to be copied from the tool definition to the NC sequence:

No—None of the tool parameters are copied automatically.

All—Copies all the tool parameters from the tool definition to the NC sequence.

Misc—Copies only the miscellaneous parameters - custom parameters, spindle direction, coolant pressure, type, and the user defined parameters specific to the NC sequence.

Cutting—Copies all the cutting conditions—feed, speed and depth. Creo NC uses the roughing condition for ROUGHING, RE-ROUGHING, VOLUME MILLING and LOCAL MILLING and the finishing conditions for all other toolpaths.

Creo NC copies these parameters based on the set configuration option only when you create an NC sequence. If you make any modifications to an existing NC sequence, you must copy the changes manually for the changes to reflect in the NC sequence.

mfg_pattern_performance_fix

yes, no*

yes—Enables a performance improvement of the NC pattern in the CL output.

mfg_process_table_setup_dir

<directory name>

In Process Manager, specifies the directory where the Process Table settings are stored. Use the full path name to avoid problems. For example, /home/users/process_mgr/table_settings.

mfg_process_template_dir

<directory name>

In Process Manager, this configuration option sets the default directory for storing all manufacturing template files created from the Process Table, including process templates and replacement templates. The specified directory is accessed by default in the following cases:

• Creating templates from the Process Table.

• Creating steps and workcells in the Process Table using  .

.

.

.• Placing and replacing templates while creating and editing annotation features, respectively.

• Replacing templates in the design model using the Update Mfg AEs command.

• Replacing templates in the manufacturing model during extraction.

• Use the full path name when you specify a value for this configuration option. For example,/home/users/process_mgr/templates. • If you do not define a value for this configuration option, the value is set to the current working directory. |

mfg_prof_rapid_feed_prev_slice

yes*, no

yes—By default, the connecting movements between slices are set to free feed or RAPID. If you set it to no, the tool speed between the end of a previous slice and start of a next slice is set to CUT_FEED. This option applies to Profile Milling sequences.

mfg_reaming_retract_feed_fix

yes*, no

yes—Enables adding ZFEED for retract feed to reaming NC sequence.

mfg_scan_tool_cutting_data

no*, yes

yes—Scans and removes the unwanted cutting data parameters of the tool referred in the relations, if such parameters exist in a manufacturing assembly.

mfg_recompute_stk_model_warning

yes*, no, auto_compute

yes—Asks for confirmation before proceeding with stock model recomputation.

no—Cancels stock model recomputation with no confirmation.

auto_compute—Recomputes the stock model automatically with no confirmation.

mfg_session_setup_dir

<directory name>

Specifies the directory where the manufacturing related setup files for the current session are stored. The tool_dialog_setup_file.xml file is one such file that stores setup information about the tool parameters.

Creo NC ignores the mfg_session_setup_dir configuration option if you specify the mfg_tool_dialog_setup_file configuration option. |

mfg_setup_file

<file name>

The absolute path to the file that stores the column setup information for the following:

• Process table in the Process Manager

• Tools Setup dialog box

• Parameters table in the Edit Parameters dialog box

This configuration option overrides the mfg_session_setup_dir configuration option.

mfg_single_grv_toolwidth_fix

yes*, no

yes*—When the tool diameter and the groove width are same, it generates a groove turning toolpath where the rough stock allowances are reflected in the toolpath as expected.

no—The rough stock allowances may not reflect in the toolpath as expected when the tool diameter and the groove width are same.

mfg_skip_synch_head_both

yes, no*

yes—The HEAD/BOTH and HEAD/OFF statement are skipped in the CL data output for synchronized steps.

no—Generates both HEAD/BOTH and HEAD/OFF statements in the CL data output for synchronized steps.

mfg_skew_circ_goto_convert_fix

yes, no*, principal_axis

yes—Converts and outputs circle records as GOTO points if the normal to the circle plane is not aligned with the tool axis.

no—Outputs circle records in the NCL file without converting circle records to GOTO points, even if the normal to the circle plane is skewed from the tool axis.

principal_axis—Converts and outputs circle records as GOTO points except when the normal to the circle plane is parallel or perpendicular to the tool axis.

mfg_solid_tool_display

yes, no*

yes—Displays the corresponding solid tool used for the playpath when using the CL player.

mfg_start_model_dir

<directory name>

Specifies the directory containing the manufacturing model templates. All the manufacturing models in this directory are available for selection as manufacturing model templates. Use the full path name to avoid problems. For example, /home/users/nc/start_models.

If this option is not set, you can use the system-supplied manufacturing templates.

mfg_stock_model_stk_file_dir

Specifies the default directory for storing the stock model information in the STK file format. Use the full pathname to avoid problems. If the default directory is not set, the stock model information is saved in the working directory.

As a best practice, use a directory on the local drive as the default directory. Avoid a directory on a remote machine for the default directory. The path to a Windchill directory is not supported. |

mfg_synch_master_slave_output

yes, no*

yes—The MASTER/SLAVE keywords are generated along with the HEAD# statement in the CL data output for synchronized steps.

no—MASTER/SLAVE keywords are not generated along with the HEAD# statement in the CL data output for synchronized steps.

mfg_tap_mat_rem_coef

1*, a value between 0 and 1

The coefficient that Creo NC uses to multiply with the estimated material removed to calculate the actual estimated material removed. This is an optional parameter. This parameter is applicable only for steps in Process Table that use tapping tool.

If you specify or modify the mfg_tap_mat_rem_coef configuration parameter for a process table step that uses the tapping tool, Creo NC does not recalculate the estimated material removed value for the step. To recalculate the estimated material removed value for the step, you must remove and add the material removal feature from the step. |

mfg_thrd_turn_output_minstp

no*, yes

Yes—Outputs MINSTP in the CL data. It is a 6-digit output that eliminates post-processing error.

No—Outputs MINSTEP in the CL data.

mfg_tool_dependency_enbld

yes*, no

This configuration option allows you to break the dependency of the Solid Tool with the Manufacturing assembly:

yes—The solid tool model is saved when you save the manufacturing assembly.

no—The solid tool model is not saved when you save the manufacturing assembly.

While retrieving the saved assembly, the solid tool is retrieved along with the assembly.

mfg_tool_dialog_setup_file

<file name>

The absolute path to the file that stores the tool parameter column setup information for the Tools Setup dialog box. This configuration option overrides the mfg_session_setup_dir configuration option.

mfg_tool_preview_by_pick

No*, Yes

Enables you to pick the position of the cutting tool after preview. You can preview the cutting tool in the graphics window.

Yes—Enables you to select a tool location on the toolpath, on a surface, on an edge, on a curve, or on a face. It could also be a vertex, datum point, or coordinate system.

No—Enables you to move the tool by dragging it in the graphics window.

mfg_traj_apprfeed_arcdash_fix

yes, no*

yes—In a Trajectory NC sequence, approach feed is considered instead of CUT_FEED if the value of ARC_FEED is set to dash (-).

mfg_traj_end_height_enable

no*, yes

yes—Enables user to select a surface to define the End height in the Curve Cut dialog box in 4-axis and 5-axis trajectory milling sequences.

mfg_trn_byarea_avoid_duplicate

no, yes *

yes—Avoids duplicate toolpath pass in area turning sequences when the STEP_DEPTH_COMPUTATION and the SCAN_TYPE configuration options are set to BY_AREA and TYPE_1_CONNECT, respectively.

mfg_turn_byarea_last_slice

yes*, no

Creates last slice in the last zone in turning sequences when STEP_DEPTH_COMPUTATION is set to BY_AREA.

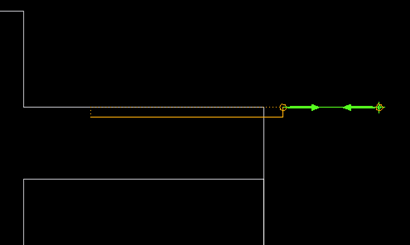

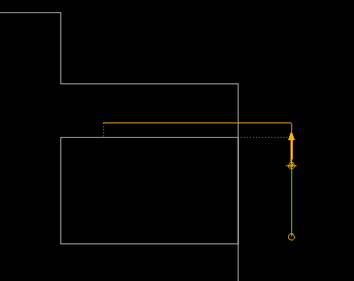

mfg_turn_iso_thread_apprexit_tm

no*, yes

yes—The approach and exit tool motions are created considering the new rectangular thread cycle in the ISO thread turning sequence.

mfg_turn_iso_thread_apprexit_tm set to no | mfg_turn_iso_thread_apprexit_tm set to yes |

|---|---|

Tool display at the end of the tool path:  | Tool display at the end of the tool path:  |

Normal Approach motion when CLEAR_DIST is set to 0:  | Normal Approach motion when CLEAR_DIST is set to 0:  |

Tangent Exit motion when CLEAR_DIST is specified:  | Tangent Exit motion when CLEAR_DIST is specified:  |

When CLEAR_DIST is set to 0, all approach motions are applied to the thread depth motion. When both THREAD_DEPTH and CLEAR_DIST are set to 0, all approach motions are applied to the cut motion. |

mfg_turn_profile_trim_shape

yes*, no

yes—Maintains consistency between turn profile preview and the actual turn profile when trim options such as, Line Connect, Trim in X, Trim in Z, or Trim to Corner options are used.

mfg_turn_rgh_prof_overtravel

yes, no*

yes—Enables overtravel on profile pass when the ROUGH_OPTION parameter is set to ROUGH_AND_PROF in Area turning.

mfg_turn_stock_gouge_fix

yes, no*

When TRIM_TO_WORKPIECE is set to YES and when Stock boundary is less than the Turn Profile, this option avoids gouge in turning.

mfg_turn_overtravel_conn_fix

yes*, no

In Area turning sequences, the END_OVERTRAVEL parameter dictates the connection passes.

mfg_volmil_clear_dist_fix

No*, Yes

This configuration option is applicable to dashboard-based volume milling sequence.

Yes—Calculates the clearance distance using the workpiece outline, mill volume ormill window, retract plane, and the user specified height.

No—Calculates the clearance distance using the workpiece outline.

The rapid motion endsand the PLUNGE_FEED begins at the clearance distance above the surface to be milled.

mfg_volmill_const_pitch_helix

No*, Yes

Yes—Generates a helical toolpath with constant pitch in Volume Milling.

mfg_vol_helicalentry_gougefix

No*, Yes

Yes—Avoids gouging during the helical entry motion in volume milling sequences.

No—Does not check for gouges during the helical entry motion in volume milling sequences.

mfg_vol_roughprof_entryexit_fix

No*, Yes

Yes—Allows you to use the combination of roughing and profiling parameters for entry and exit motions.

For combined roughing and profile passes, such as ROUGH & PROF, POCKETING, you must select the LEAD_IN, NORMAL, or the LINE_TANGENT option for the CUT_ENTRY_EXT and CUT_EXIT_EXT parameters. These options drive the profile passes.

The entry and exit motions for rough passes are driven by the values of the RAMP_ANGLE and HELICAL_DIAMETER parameters that are independent of the values of CUT_ENTRY_EXT and CUT_ EXIT_EXT

For ROUGH_ONLY or PROF_ONLY passes, you must select appropriate CUT_ENTRY_EXT and CUT_EXIT_EXT values. For example, RAMP or HELIX for ROUGH_ONLY passes.

mfg_warn_del_ft_act_in_sync

yes, no*

yes—Issues a warning when a feature used in synchronization is being deleted or suppressed.

Also, issues a warning when launching synchronization again if such a feature has been deleted or suppressed.

mfg_workpiece_transparency

<decimal number>

Controls the workpiece transparency in shaded model display. You can change the value in the range between 0.1 and 1. The bigger the value, the more transparent the workpiece. The default value is 0.5.

If you change the mfg_workpiece_transparency value, it affects only the newly assembled or created workpieces. When you retrieve a manufacturing model, its existing workpiece is not affected by the current value of the mfg_workpiece_transparency option. For more information, see the topic Workpiece Display. |

mfg_xyz_num_digits

<integer number>

Sets the number of digits for x, y, z tool coordinates in a CL data file. The default is 10.

nc_autodoc_param_dir

<directory name with full path>

Defines the location of the setup file. This file describes the process parameters to be included in the parameter table.

nc_autodoc_report_dir

<directory name with full path>

Defines the location to store the report and images created when you generate a shop floor report.

nc_autodoc_setup_dir

<directory name with full path>

Defines the location of the documentation setup files. These file describe the process parameters to be included in the parameter table.

nc_autodoc_template_dir

<directory name with full path>

Defines the location of the stylesheet and default images to be used in the shop floor report. If you do not set this configuration option, Creo Parametric uses the report template and default images stored in the Creo Parametric load point.

nc_jobman_visible

no*, yes

yes—Enables the Job Manager functionality, which allows you to compute the tool path for an NC sequence out-of-process, whether remotely or on the same machine, while you continue working on other NC sequences, or other Creo models.

nccheck_type

ModuleWorks*, nccheck, external

Controls which NC Check simulation module to use:

• ModuleWorks—Use an integrated simulation environment on the Material Removal tab.

• nccheck—Use NC-CHECK.

• external—Use an external tool.

ncl_file_extension

<file extension>

Sets the default file extension for CL data files. If you do not set this option, the default CL file extension is .ncl.

• File extension length is limited to 3 characters. If you specify a longer file extension, it will be truncated and a warning will be issued. • Do not change the CL file extension if you are using a default post-processor, a dedicated post-processor, or a post-processor created with NCPOST. |

ncpost_type

gpost*, ncpost

Each Creo NC module includes a standard set of NC post-processors that can be executed directly or modified using an optional module. This configuration option controls which post-processing module to use:

• gpost—Use the G-Post™ post-processors provided by Intercim Corporation.

• ncpost—Use the NCPOST post-processors.

output_start_goto_pnt_of_seq

yes, no*

yes—Outputs duplicate GOTO point at the start of NC feature, if previous NC feature ends at same GOTO point.

pro_mf_cl_dir

<directory name>

Sets the default directory for the manufacturing CL data files. Use the full path name to avoid problems. For example,

/home/users/library/mfg_cl.

pro_mf_param_dir

<directory name>

Sets the default directory for the manufacturing parameter files. Use the full path name to avoid problems. For example, /home/users/library/mfg_params.

pro_mf_tprm_dir

<directory name>

Sets the default directory for the manufacturing tool files. Use the full path name to avoid problems. For example,

/home/users/library/toolcrib.

pro_mf_workcell_dir

<directory name>

Sets the default directory for the manufacturing workcell files. Use the full path name to avoid problems. For example, /home/users/library/workcells.

pro_mfg_cmdsyn_dir

<directory name>

Sets the default directory for the syntax menu files in Creo NC. Use the full path name to avoid problems. For example, /home/users/library/mach_cmdsym.

profile_output_utils

yes, no*

This option affects the CL data output for Profile milling sequences:

• yes—NC sequence parameter OUTPUT_POINT is available with the following options:

◦ TIP—The tool path is output with respect to the tool center

◦ ON_PROFILE—The tool path is output with respect to the profile of the tool.

• no—NC sequence parameter OUTPUT_POINT is not available

proncpost_dbf

<file name>

Specifies the location and name for NCPOST database file. Use the full directory path and name.

prorembatch_queue_manager

<proc_name>:<host>:0:<proc_num>:1

Enables tool path computation on a separate host machine.

The elements are as follows:

• <proc_name>—Processor name (can be any descriptive name).

• <host>—Remote machine’s hostname.

• 0—Type of transport, always set to 0.

• <proc_num>—RPC number of processor. Must match the PRORB_RPCNUM environment variable on remote machine; if you specify 0, the system will use the default RPC number.

• 1—Version of queue manager, currently 1.

remove_mfgpat_inst_frm_table

yes, no*

yes—Removes the NC pattern instance name from the Pro/TABLE of the drawing.

reverse_spiral_finish_type

0, 1, 2

This configuration option is applicable to the Finishing steps when the FINISH_OPTION parameter is set to SHALLOW_CUTS or COMBINED_CUTS and SHALLOW_AREA_SCAN parameter is set to SPIRAL_SCAN.

The configuration option accepts three values: 1, 2, and the default value 0. Any other value is treated as a default value.

For the default value 0, one of the following options set for the SPIRAL_SCAN_DIRECTION parameter is considered.

• INSIDE_OUT—Toolpath starts from inside and follows the outer boundary.

• OUTSIDE_IN—Toolpath starts from outside and follows the outer boundary.

For value 1: Regardless of the option set for SPIRAL_SCAN_DIRECTION, the toolpath starts from inside and follows the outer boundary.

For value 2: Regardless of the option set for SPIRAL_SCAN_DIRECTION, the toolpath starts from inside and follows the constant load strategy.

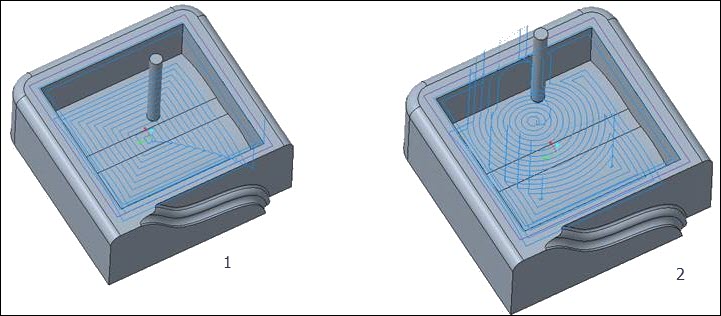

1. Toolpath for value 1

2. Toolpath for value 2

shade_mfg_ref_models

yes*, no

yes—Shades reference parts when generating shaded images.

no—Does not process reference parts when generating the shaded image. This saves time.

skip_relation_mfg_process_xml

yes*, no

yes—Omits the relation strings in the CAD document of the NC assembly.

The configuration option dm_nc_process generates the NC process information as part of the CAD Document of the NC Assembly in the XML Format whenever the CAD documentis saved. If you have many sequences with numerous parameters, and if you set the dm_nc_process configuration option to yes, it takes longer to save the document.

Set the skip_relation_mfg_process_xml configuration option to yes to delete the relation strings from the output and save the CAD document faster.

smmp_add_rapid_for_punch

yes, no*

yes—Adds the RAPID command to the CL output file when avoiding a clamp in PUNCH.

solid_tool_offset_num_validate

yes, no*

yes—An offset number of solid multi-tap tool that you enter is validated.

store_tool_path_file

yes*, no

Specifies how manufacturing tool path information is computed:

• yes—The tool path information is stored in a file called filename.tph, where filename is the name of the manufacturing model.

• no—The tool path is recomputed every time you retrieve the manufacturing model or change any manufacturing parameters.

suppress_hsm_progress_dialog

yes, no*

yes—Suppresses the Toolpath calculation progress window for the HSM sequences.

tapping_use_brkout_dist_enbld

yes, no*

yes—The Use breakout distance option is selected, and the value of the BREAKOUT_DISTANCE parameter is used for calculating the depth in the Tapping NC sequence.

template_mfgcmm

<assembly name>

Enables you to specify the model that is used as the default start model for CMM. Use the full directory path and name.

template_mfgemo

<assembly name>

Enables you to specify the model that is used as the default start model for Expert Machinist. Use the full directory path and name.

template_mfgnc

<assembly name>

Enables you to specify the model that is used as the default start model in Creo NC.

Use the full directory path and name.

tool_motion_list_length

<integer number>

Controls the number of rows visible in the tool motions list without scrolling. This value is applicable to all dashboard-based NC steps.

tool_path_preview_default

on, off, auto*

Controls whether the tool path preview is displayed by default when creating a new step or editing an existing one.

• on—Displays the tool path preview.

• off—Does not display the tool path preview.

• auto—Displays the tool path preview for certain tool paths.

travel_bounds_display

No*, Yes

Specifies whether the machining limits of a workcell are visible or not.

Yes—Displays the machining limits of a workcell.

travel_bounds_tranparency

<decimal number>

Controls the transparency of the highlighted machine limits. You can change the value in the range between 0.1 and 1. The bigger the value, the more transparent the highlighted machine limit. The default value is 0.8.

turn_output_cutcom_tm_apprexit

yes, no*

When you manually set the approach and exit motions and set the CUTCOM parameter to ON, the CL data outputs accurate CUTCOM statement as per the cut direction.

yes—The CL data shows accurate cutter compensation for approach and exit tool motions in turning sequences.

use_mmks_units_for_ejpin

yes, no*

yes—Uses the MMKS unit system when creating ejector pins.

use_stdtip_osetno_for_flashtip

yes, no*

yes—If the tip with Flashed orientation does not have an offset number, the tip uses the offset number of the corresponding tip with Standard orientation and outputs it in the NCL file.

wcell_fixt_info_setup_file

<file name>

Enables you to specify the path to the workcell-fixture information setup file. This is a .xml file that stores the information about workcells and the compatible fixtures for each workcell. The workcell fixture compatibility functionality in the process table is available only if you specify the wcell_fixt_info_setup_file configuration option.

workpiece_instances

none, operations, steps, operations_and_steps

Specifies the way Creo Parametric generates geometric representations of the workpiece during the manufacturing process.

• none—Geometric representations are not generated.

• operations—Geometric representations are created for each operation and named as <workpiece-name>_<operation-name>.

• steps—Geometric representations are created for each step and named as <workpiece-name>_<step-name>.

• operations_and_steps—Geometric representations are created for steps as well as operations.