About Working with Standard Parts from Windchill

To assemble standard parts from Windchill, the following configuration tasks must be performed.

Provide a Custom Configuration using the EMX _USER_CONFIG_PATH variable

In the beginning, it is necessary to provide a custom configuration.

The goal is that all users within a company are working with the same configuration.

1. Copy the standard configuration folder emx-installation-path\configuration from the EMX installation to a server location visible for all users, such as "<server-path>\emx-adaptions\configuration".

This folder should have writing restrictions for all users and should only be modified by the administrator.

2. Set the Windows variable EMX_USER_CONFIG_PATH to the value <server-path>\emx-adaptions for all users. EMX will then find the custom configuration at this location.

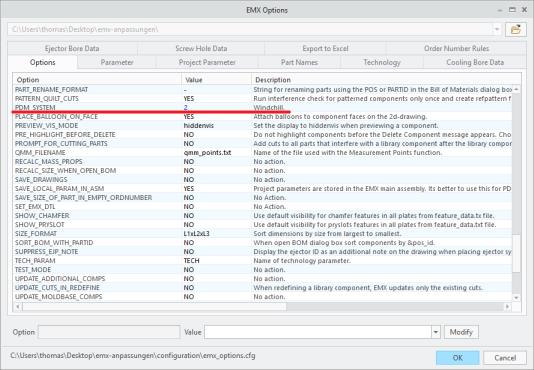

Set EMX Option PDM_SYSTEM

1. In EMX Options  , set the configuration option PDM_SYSTEM to 2 - Windchill.

, set the configuration option PDM_SYSTEM to 2 - Windchill.

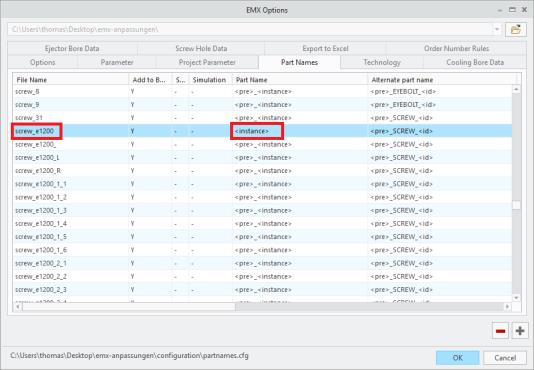

Configure Part Names in EMX Options

In > , adapt the part name rules so that the resulting part name is project-independent.

Remove ID (<id>) or project prefix (<pre>).

1. For screw E1200 with the according template file screw_E1200.prt, set the part name rule to <instance>.

As a result, the name is E1200_8_60. These instance names come from the dimension tables in the *.dat file.

Reduce Variety of Selectable Components in the Screw Dialog Box

When working with standard parts from Windchill, it is recommended to provide the component types which are administered in Windchill.

To achieve these goals, reduce the available suppliers and screw types.

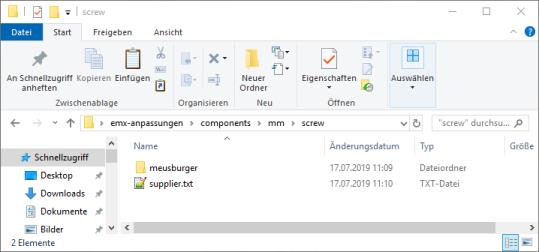

You can restrict the supplier list by providing an adapted supplier.txt file in the appropriate location. This file needs to be placed at the following path in the custom configuration at EMX_USER_CONFIG_PATH\components\mm\screw\supplier.txt

You can copy the equivalent file from the EMX standard installation at <emx-installation-path>\components\mm\screw\supplier.txt

A file located in the custom configuration has a higher priority than the equivalent file from the standard installation and will be used by default.

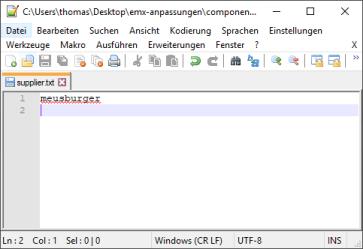

1. In the given example, the content of the file supplier.txt is therefore reduced to meusburger.

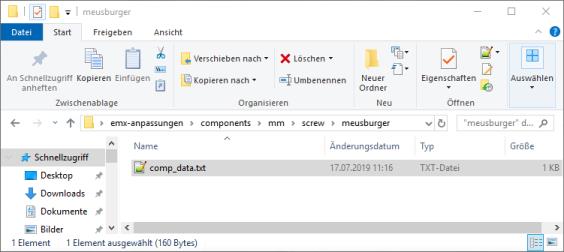

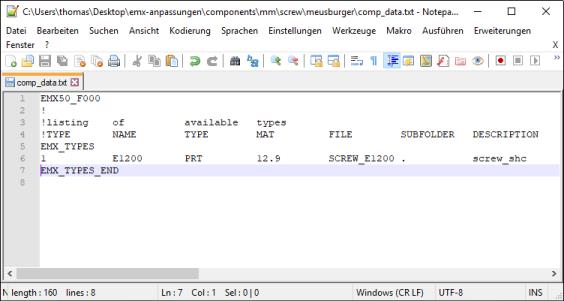

Restrictions for screw types follow a similar pattern. An adapted comp_data.txt file needs to be created. The location is inside a supplier specific folder: EMX_USER_CONFIG_PATH\components\mm\screw\meusburger\comp_data.txt

As a template, you can copy the equivalent file from the EMX standard installation: <emx-installation-path>\components\mm\screw\meusburger\comp_data.txt

In the comp_data.txt file, delete all lines except the relevant E1200 line.

In the screw dialog box, only E1200 screws from Meusburger can be assembled.

Create All Screw Instances

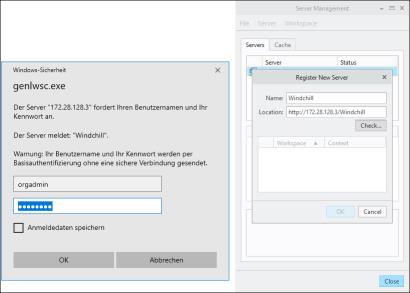

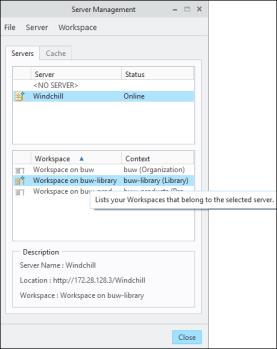

Before creating all instances of the E1200 screw, you must connect to the Windchill-Server and login as an administrator.

You must also activate the Workspace for the Windchill library.

Using the Component Editor  all instances of a component can be created.

all instances of a component can be created.

Perform the following steps:

1. Click Component Editor  .

.

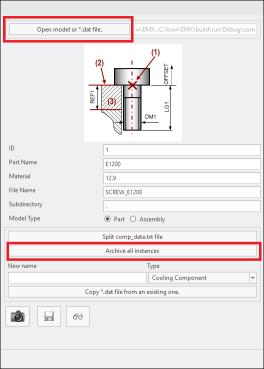

2. Open the file E1200.dat located in the standard installation directory <emx-installation-path>\components\mm\screw\meusburger\E1200.dat using Open model or *.dat file

3. Click Archive all instances. All Instances are saved to the current workspace.

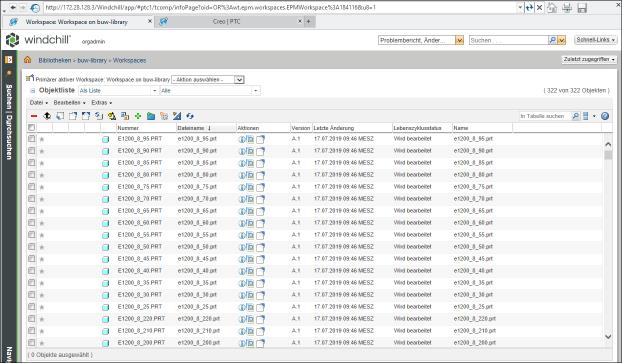

Check in all Instances to the Windchill Library

To provide the created instances to all users, you must save the models in a structured way in the Windchill library.

It is recommended to use a folder structure similar to the folder structure in the EMX standard installation.

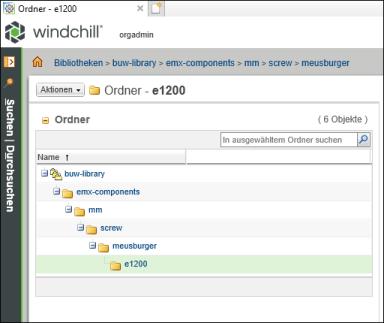

For example, for screw Meusburger E1200, the following structure is used.

buw-library > emx-components > mm > screw > meusburger > e1200

Using this structure has several advantages.

• EMX standard parts in the library can be extended in the future.

• Models are easy to locate.

Using the Windchill Check-In mechanism, you can store files in the e1200 folder.

EMX is now fully configured and screws can now be placed from Windchill.

Assembling EMX Components from Windchill (User)

From a user perspective not much changes during the assembly procedure of components.

However, within the screw dialog box you can locate the source of the model.

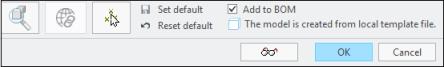

When a model is found in the common space by the part names rule, an additional icon with a short message The model is found in common space is displayed in the bottom area of the dialog.

When no model was found in common space and the standard assembly procedure is used, an alternative message The model is created from local template file appears.

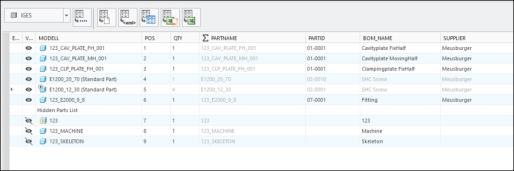

Additionally, the standard part status is also visualized in the Bill of Materials. Parameters can not be edited and are therefore disabled.