About Advanced Manufacturing Resource Browser

Planning is important when setting up a manufacturing plant. The Advanced Manufacturing Resource Browser feature in MPMLink helps you to plan and set up a manufacturing plant. The Advanced MRB is available when certain actions are performed in the Manufacturing Resource Browser (MRB).

Consider the following scenario:

• A car engine manufacturing company has its corporate office in Sweden.

• All the manufacturing processes are controlled from a central location, in Sweden. The central location is also known as the specification plant or master plant. In MRB, the central location may or may not be a physical manufacturing plant.

• The specification plant in Sweden determines and then creates the standards, specifications for the manufacturing units, manufacturing strategies, and the manufacturing process to be implemented in the manufacturing plants.

• Manufacturing plants are in Brazil and India. The manufacturing plants, are actual physical plants. All the manufacturing processes in the manufacturing plants are controlled from the central location in Sweden.

• The manufacturing plants in Brazil and India follow the specifications set by Sweden.

The structure of the operations to be implemented in the central and other plant locations is created in the MRB. To perform any operation related to manufacturing, you need machines such as industrial robots, milling machines and so on. Sweden, the central location, defines the specification of the machines in Brazil and India that must be used to perform the manufacturing operations. Although the machines in Brazil and India may not be from the same manufacturer, the machines must all satisfy the specifications defined by Sweden.

In MRB you can create a structure of operations, by creating two plant structures:

• A structure depicting the central location

• A structure depicting the actual manufacturing plants.

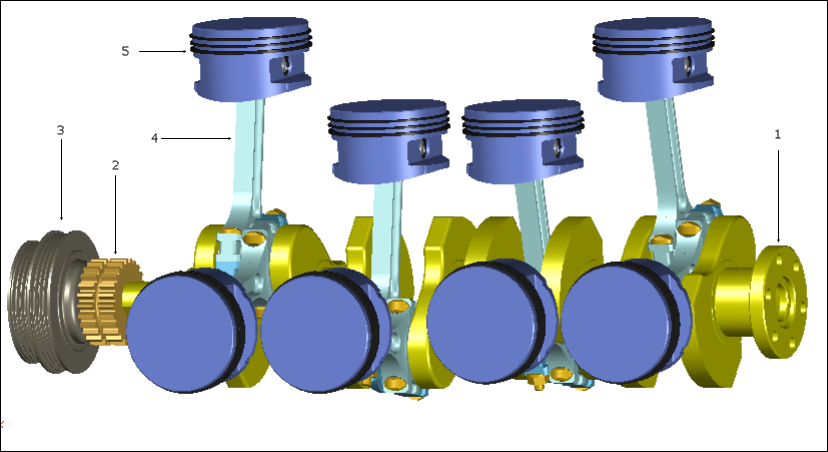

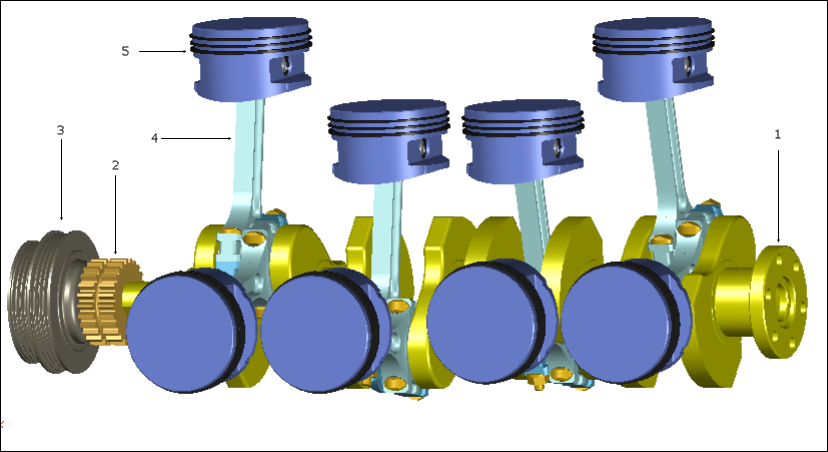

The procedures that follow make up a workflow for assembling a part of the following engine assembly. The engine assembly consists of five main parts:

1 – Crankshaft Assembly

2 – Sprocket

3 – Pulley

4 – Connecting Rod

5 – Piston Assembly

For this workflow, the SCARA and 6-Axis machines, and Delta industrial robots are used to perform the various assembling operations.

If you were creating a manufacturing plant setup in MRB to manufacture the above assembly, you would perform the steps described in each section of following workflow: