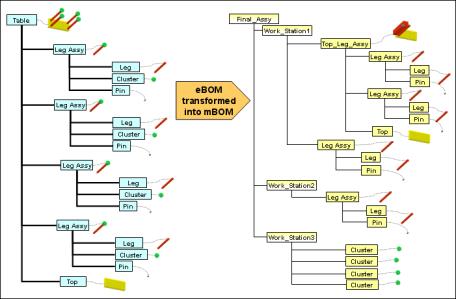

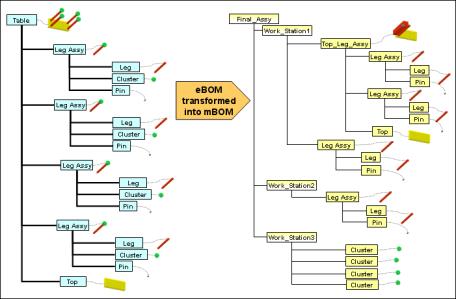

Transforming an eBOM into an mBOM

Transforming an engineering bill of materials (eBOM) into a manufacturing bill of materials (mBOM) is a key component of the manufacturing process. Typically the as-designed, or engineering view of how a product is to be produced, differs from the as-planned, or manufacturing view of how the product is intended to be built.

Windchill MPMLink allows both design and manufacturing engineers to not only modify their respective bill of materials, but to maintain associative BOM links (equivalent links) between the two. This ensures that any changes made to the design of a product are communicated to the manufacturing engineers, and the impact of such changes are immediately known.

| This procedure can only be used if you have set your Pasting Parts preference to Paste with Associative BOM Links. |

The transformation of an eBOM into an mBOM can be done in the following ways:

• By renaming eBOM parts (New Part Number):

Use when the eBOM parts and the mBOM parts must have different part numbers, or when multiple mBOM assemblies are to be used for a single eBOM assembly.

• By re-using the eBOM part in the mBOM (Add selected part):

Use when the eBOM part does not need to be changed when used in the mBOM, and when no separate management (for example change management, effectivity, revision, etc.) of the part is needed.

Use when the mBOM part retains the same part number as the eBOM part, but separate management is required.

• By using the Visualization tab to copy and paste parts.

| Not all engineering parts require transformation when planning their manufacturing. In this case, the engineering part can be used as-is in a parent manufacturing assembly. |