Occurrences

In Windchill, an occurrence stores information about one named use of a part within an assembly part structure. The number of occurrences is related to the quantity of the part used in the next higher level assembly. You can define a number of occurrences equal to or less than the quantity value.

The name of an occurrence is stored in the Reference Designator attribute. Occurrences are created when Reference Designator names are defined. Attributes that are unique to an occurrence can be defined once the occurrence objects are created in the database.

For example, suppose you are working with the part structure of an automobile. The part structure for the automobile uses four wheels. A series of spatial coordinates defines the location of the wheels in the automobile, with one set of coordinates for each of the four occurrences of the wheel in the automobile. Once the occurrence for each wheel is defined and assigned a reference designator, the location attribute can be added. Storing the location information with each occurrence makes it possible to select the right-front wheel in the part structure and see that occurrence highlighted in the assembly image.

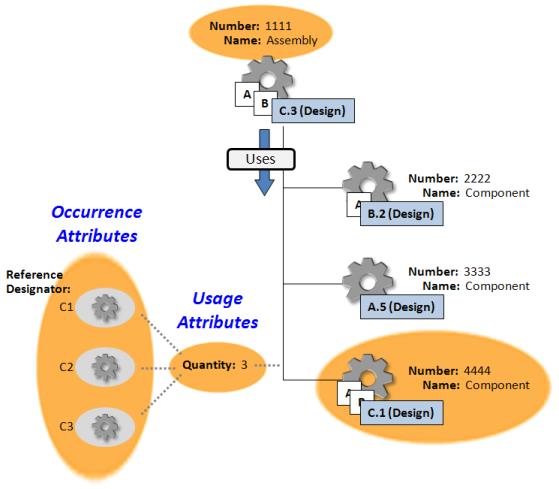

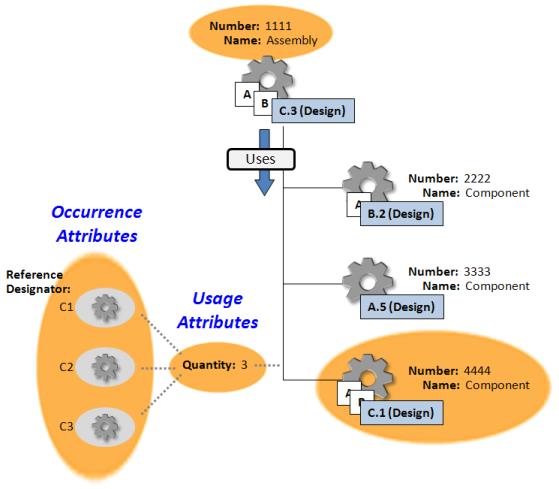

The following example shows how occurrence information is stored in a part structure:

In this diagram, assembly number 1111, version C.3 Design uses a quantity 3 of part number 4444. The values of the Reference Designator attribute are defined as “C1, C2, C3” which creates three named occurrences.

To learn more about creating and viewing occurrence information, see: