Working with Homogenized Lattices in Creo Simulate

About Homogenization

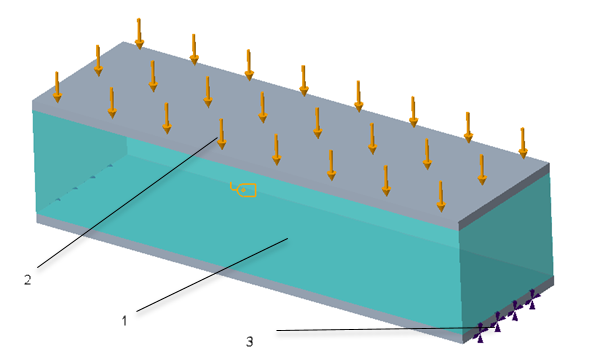

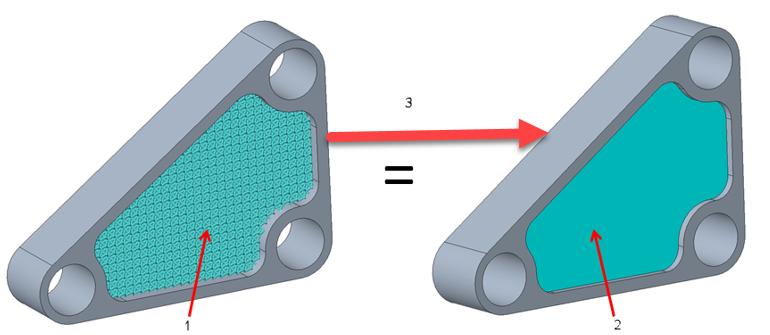

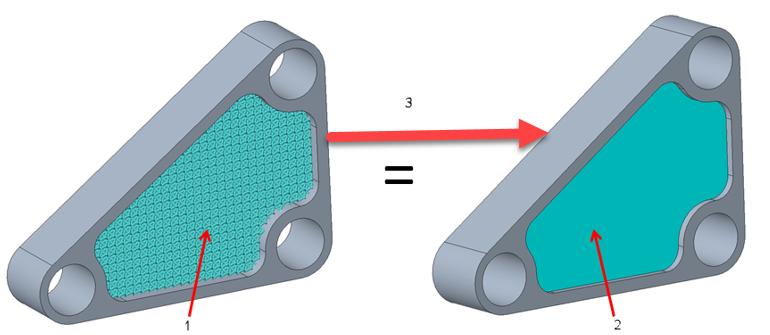

If the number of cells in a lattice is large—that is greater than 24,000, it is impractical to store or simulate full or simplified geometry models since these tasks require a considerable amount of computational resources. When the object to be modeled contains a very large number of repeated lattice cells, then the behavior of the object is similar to that of a body that consists of a continuous material. To facilitate the modeling of large lattice structures, the lattice structure is represented as a continuous solid with effective material properties that are equivalent to those of the lattice structure. A solid with these effective material properties will have the same mass properties, stiffness, thermal conductivity, porosity etc. as the original lattice structure. The derivation of these effective material properties is called Homogenization.Creo 6.0 uses homogenization methods that facilitate the modeling of large lattice structures by computing and providing Creo Simulate the equivalent effective properties. The process is depicted graphically in the figure below.

1. Lattice structure

2. Homogenous Continuum

3. Process of Homogenization

Workflow for Running an Simulation Analysis with a Homogenized Lattice

Create lattice features for homogenized volumes by using options on the Lattice feature tab in Creo Parametric.

1. Create a solid model or open an existing model.

2. On the Lattice feature tab in Creo Parametric , note the following when creating a lattice feature for homogenized volumes:

◦ Select

Homogenized

Homogenized for the representation of the lattice.

◦ If you select Create shell on the Lattice Region tab, ensure that the homogenized volume is not fully enclosed. Select at least one excluded shell surface for the homogenized volume.

◦ Select Beams for Lattice Type.

◦ Select one of the following supported cell shapes on the Cell Type tab:

▪ Square

▪ Hexagonal

▪ Octagonal

3. After defining homogenized volumes in a part, open the part in Creo Simulate. The homogenized volume is displayed in a different color (cyan) in order to differentiate it from the rest of the model.

1. Homogenized Volume

2. Applied Load

3. Applied constraint

4. Assign loads, constraints and materials to the model. The material that is assigned to the homogenized volume must have anisotropic material properties.

5. Create a linear static analysis or a modal analysis.

6. Run the analysis. Creo Simulate creates a unit cell or RVE for the volume that you want to represent as a homogenized lattice and runs two successive analyses as follows:

◦ The first analysis is a background analysis that runs on the unit cell or RVE (representative volume element). In this step the equivalent homogenized material properties are calculated for the RVE.

◦ In the second step the user-defined analysis runs. It uses the equivalent material properties that are calculated in the previously run background analysis. The homogenized material properties that include the equivalent material density and the values of the 6x6 skyline stiffness matrix (upper triangular) are available in therpt file in the analysis folder. These values are used to run the second analysis that is the user-defined analysis.

◦ Evaluate results when the analysis completes.

Homogenized for the representation of the lattice.

Homogenized for the representation of the lattice.